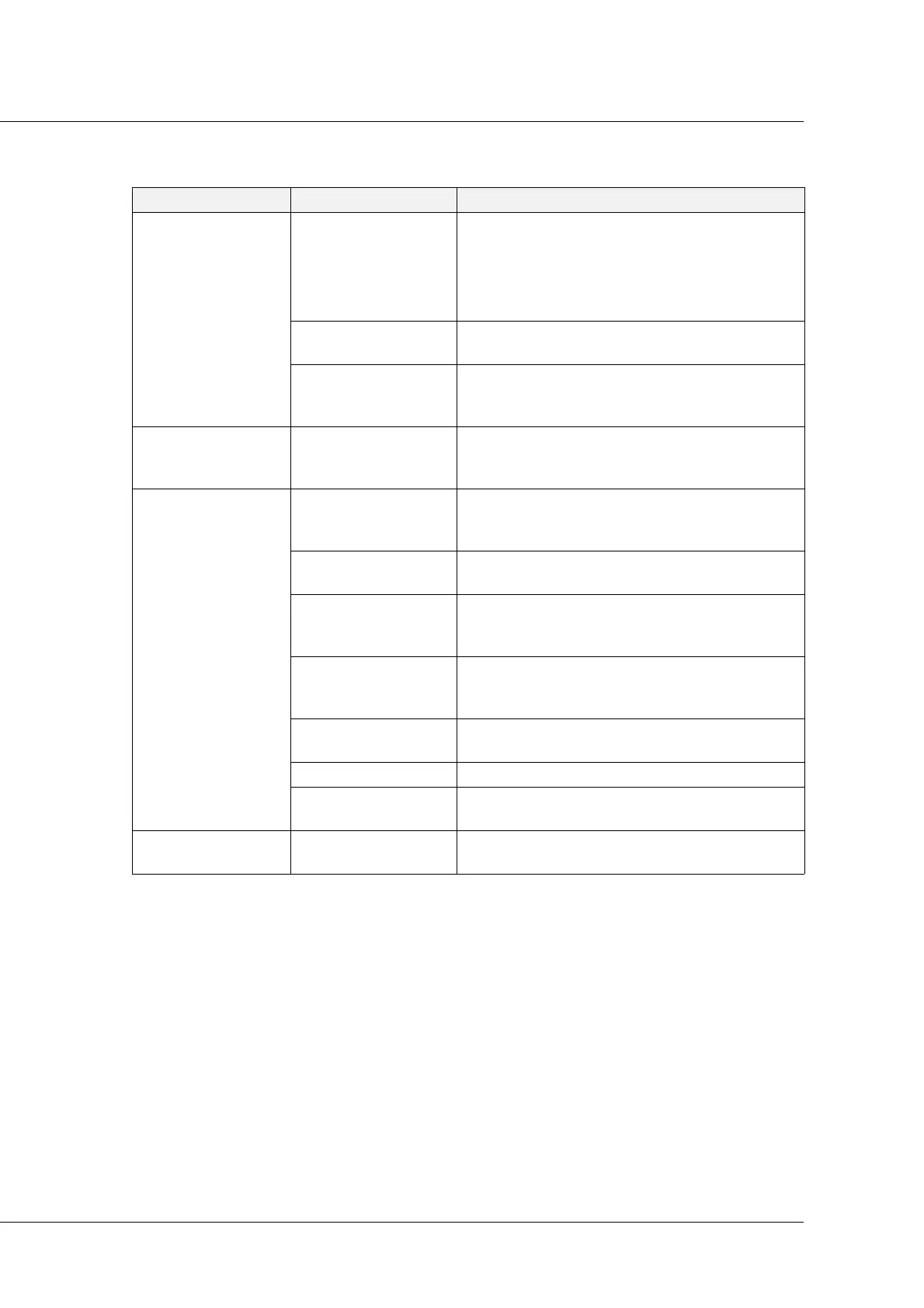

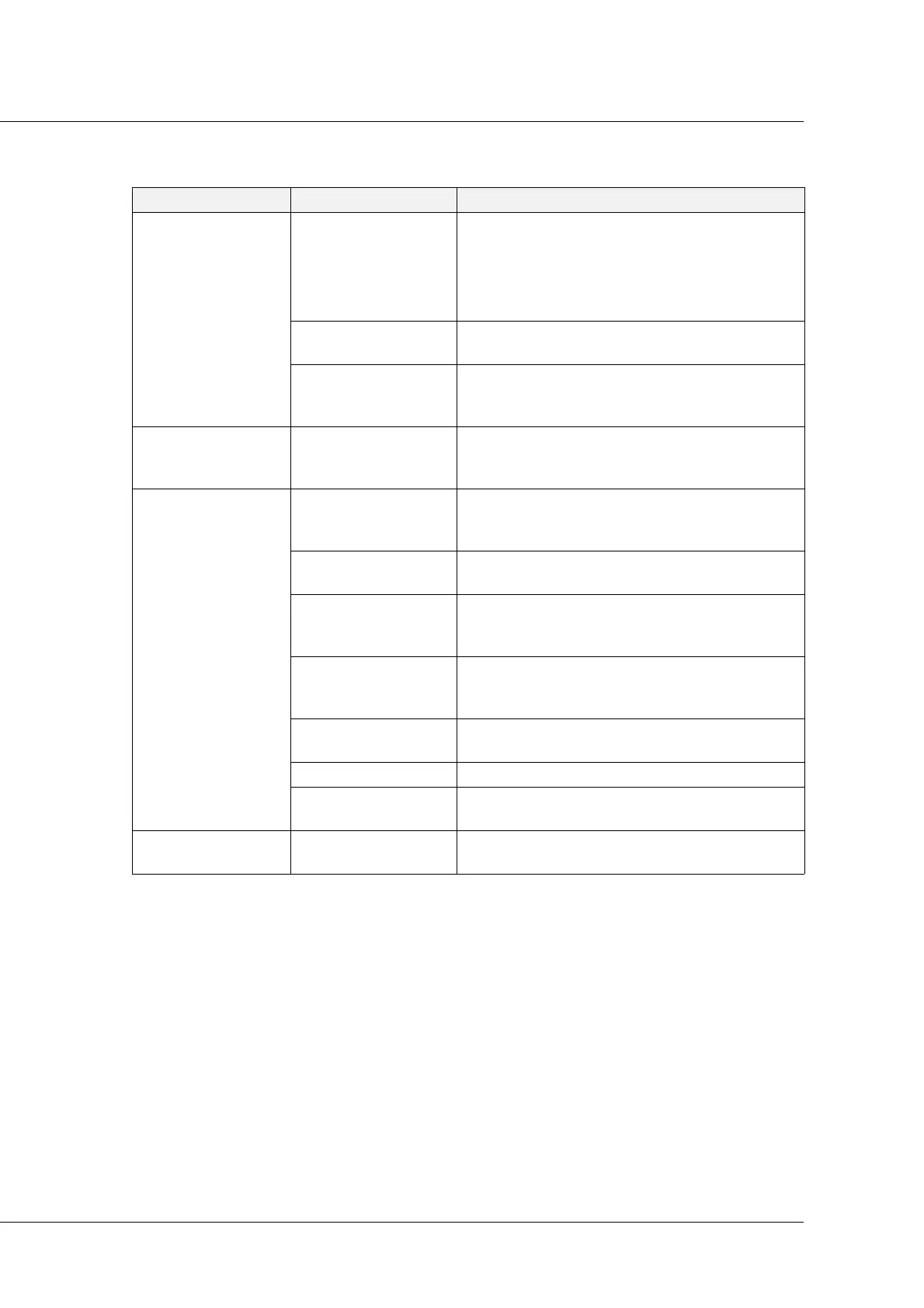

10 Troubleshooting

HSD S.p.A. © - 0110h00a.fm100713

115

The electrospindle

overheats:

Insufficient cooling: Check the specifications of the system in

section 4.7 “Cooler specifications and

hydraulic connections”;

Check the integrity and efficiency of the

cooling circuit.

Machining is too

heavy:

Lighten the machining.

The inverter

parameters are

incorrect:

Check the parameters on the electrospindle

plate in chapter 2 “Technical Specifications”

(in the paragraph relating to your model).

Performance lower

than specifications:

The inverter

parameters are

incorrect:

Check the parameters on the electrospindle

plate in chapter 2 “Technical Specifications”

(in the paragraph relating to your model).

Electrospindle

vibrates:

The tool holder is not

balanced:

Choose a tool holder according to the

indications described in section 6.5.1 “Tool

holder cone”.

The tool is not

balanced:

Choose and use the tool as shown in

section 6.6 “Tool”.

Dirt between the tool

holder cone and

shaft-spindle:

Remove the macroscopic impurities and

clean as described in section 7

“Programmed maintenance”.

The inverter

parameters are

incorrect:

Check the parameters on the electrospindle

plate in chapter 2 “Technical Specifications”

(in the paragraph relating to your model).

Machining is too

heavy:

Lighten the machining.

Fixing screws loose:

Tighten the fixing screws:

Bearings damaged:

Contact the manufacturer's assistance

service.

Bearings noisy: Bearings damaged:

Contact the manufacturer's assistance

service.

Problems Cause Remedy

Loading...

Loading...