4 Installation and commissioning

54

HSD S.p.A. © - 0104h03a.fm100713

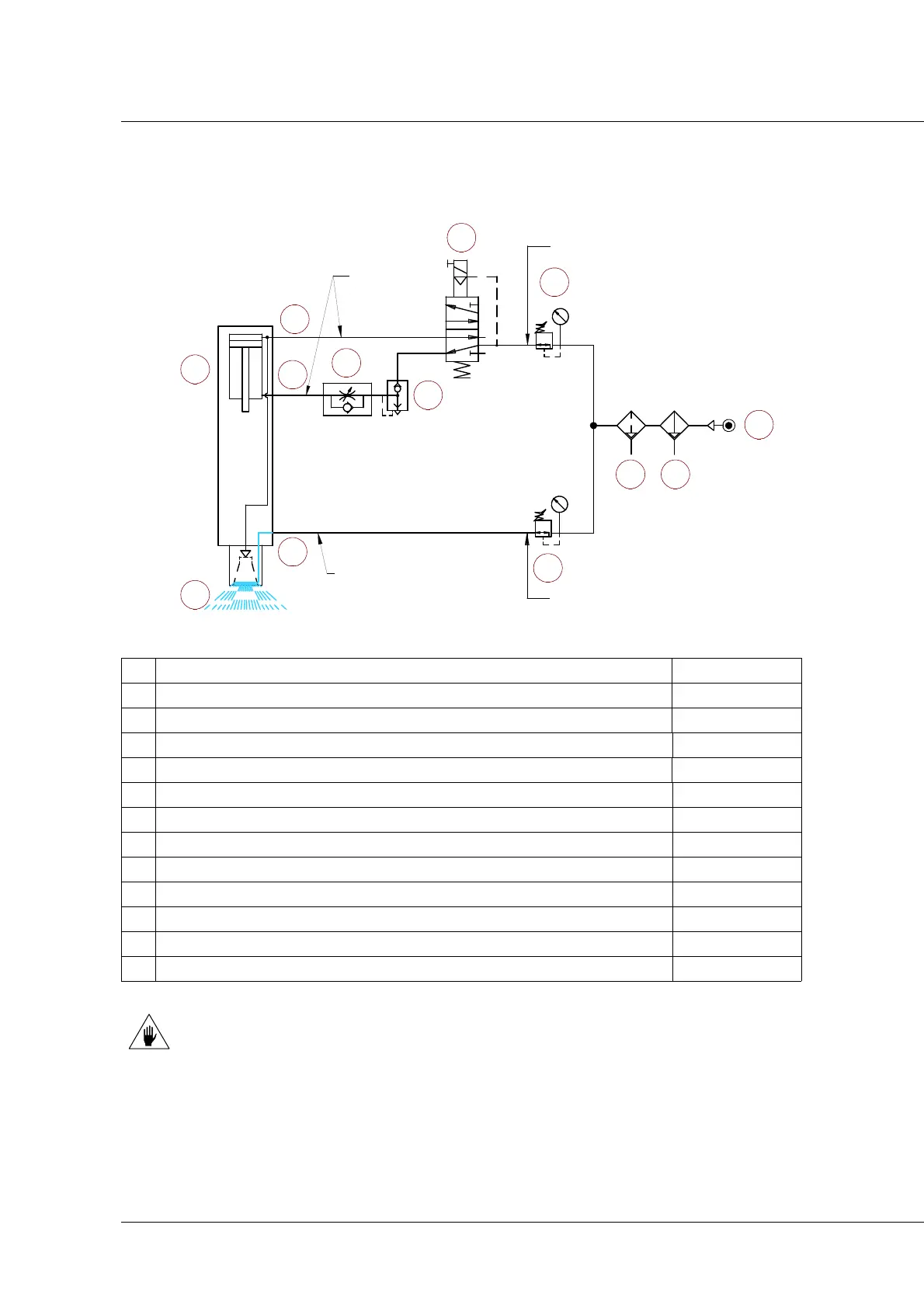

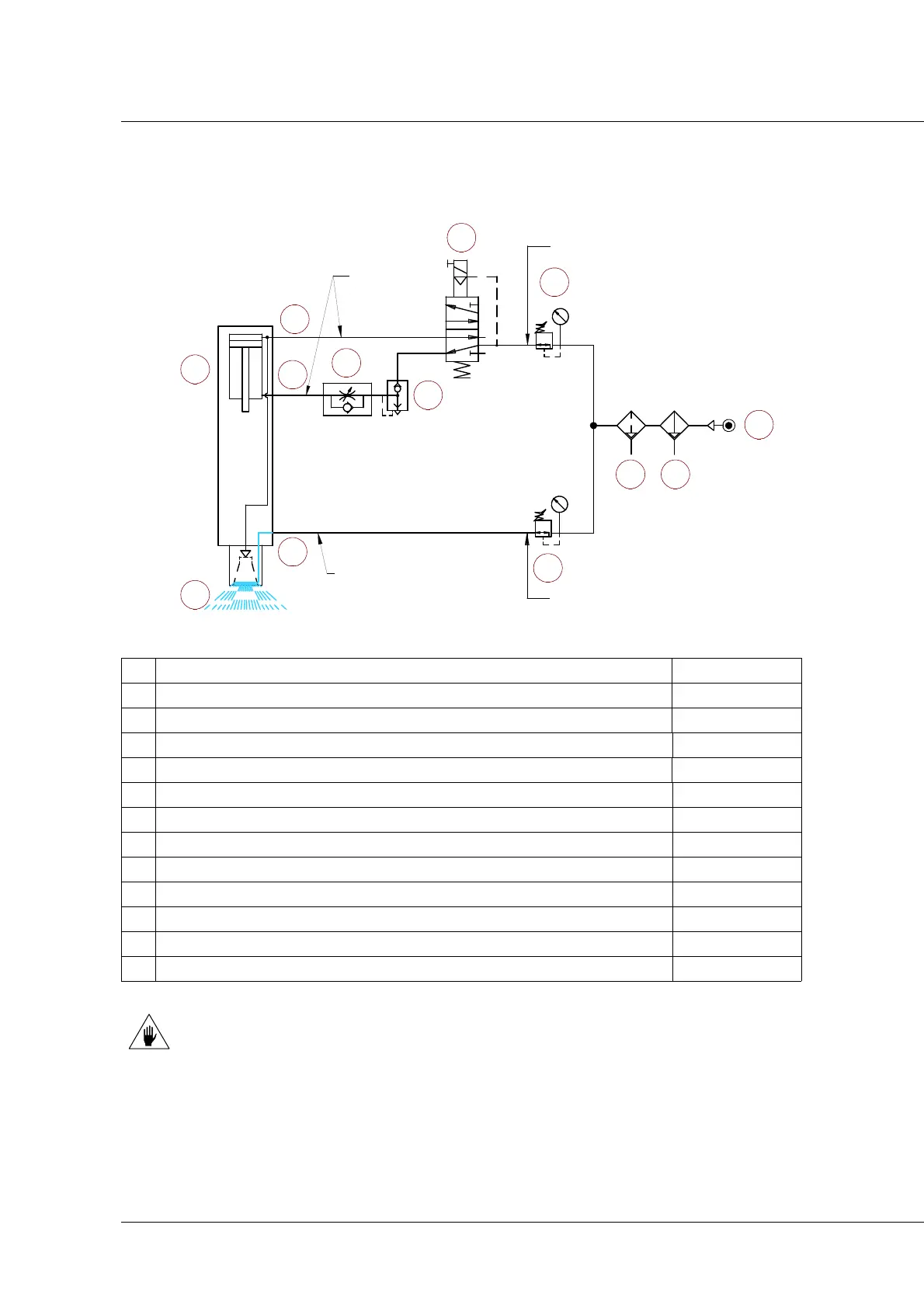

Figure 3: exemplary pneumatic layout for ES330 “air” electrospindle

1 Air inlet for tool release and cone cleaning 6 bar - 87 PSI

2

Tool locking air inlet (piston return) 6 bar - 87 PSI

3

Double effect piston

4 Unidirectional flow regulator for regulating the ejection speed

5

Rapid discharge valve

6 Monostable 5-2 valve with electro-pneumatic control and spring return

7 Pressure regulator with pressure switch calibrated to 6 bar

8 Oil separator filter 0.1 µm.

9 Pre-filter 5 µm

10 Mains power supply

11 Continuous flow of pressurisation air

12 Pressurisation air inlet 0.5 bar - 7.3 PSI

13 Pressure regulator with pressure switch calibrated to 0.5 bar

THE PROPOSED CIRCUIT IS PURELY EXEMPLARY.

1

13

8 9

10

1

5

3

42

3

4

6

7

2

11

12

O4x2

5

6 Bar

0,5 Bar

O8x6

Loading...

Loading...