6 Operation and regulation

82

HSD S.p.A. © - 0106h03a.fm100713

Use and technical characteristics of the thermal alarm

The electrospindle may be fitted with a normally-closed bimetallic strip switch inserted in the

electric windings of the stator which opens when a temperature that may damage the windings is

reached. The contacts re-close when the temperature reduces and returns to the safe values.

The thermal alarm must be connected to the Numerical Control, which should interrupt the

machining operation and stop the rotation of the spindle shaft if the switch opens.

For the bimetallic strip switch connection, see section 4.9 “Electronic connections for models with

free cables”.

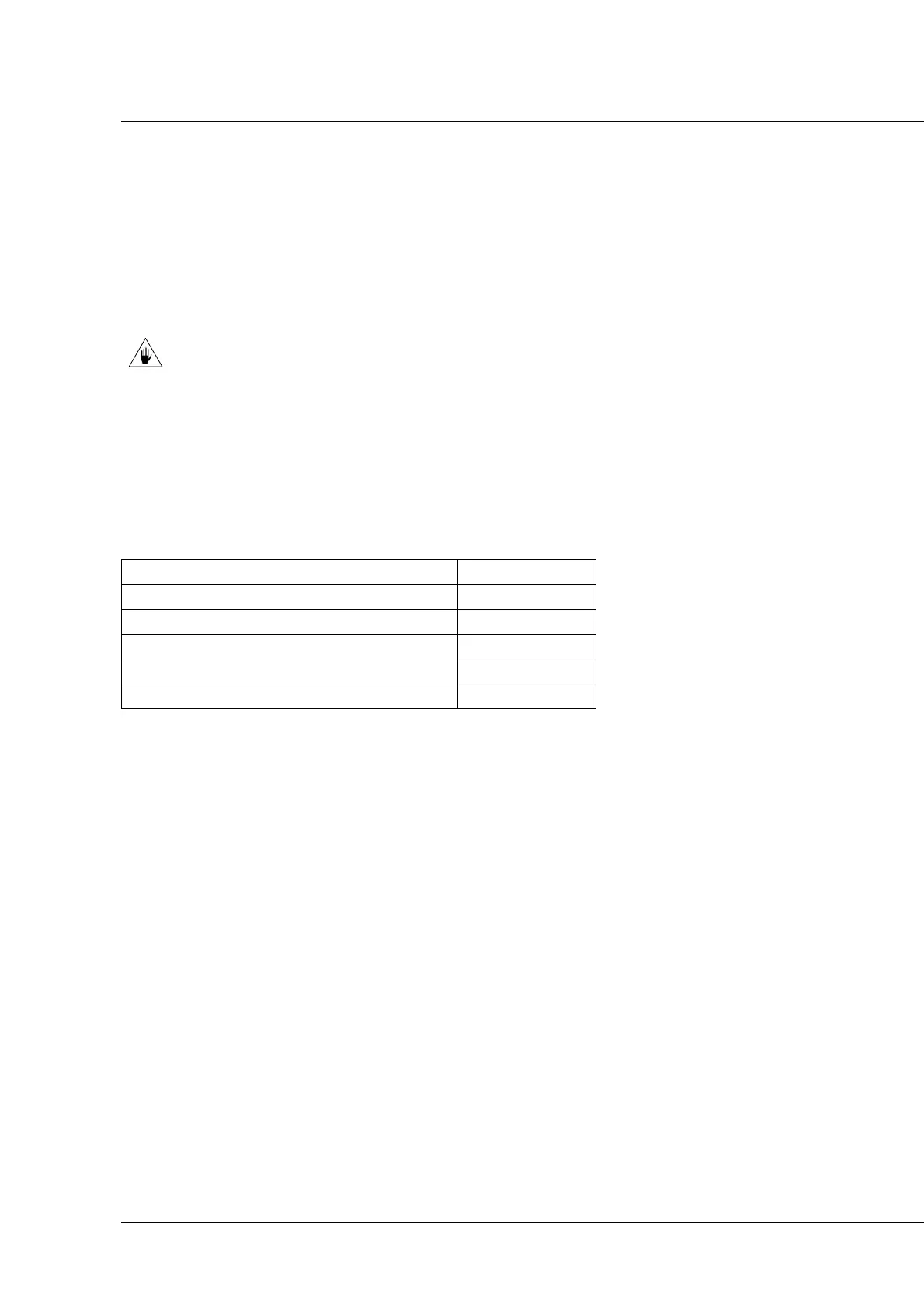

Technical characteristics of the bimetallic strip:

PTC Thermistor

In some versions, a PTC thermistor may be inserted into the stator windings to check the

temperature. When the operation temperature has almost been reached (130° C), resistance

increases briskly. This signal must be used by a device which stops the machine to protect the

electrospindle. The operation temperature threshold varies according to the type of electrospindle

(for further information contact the manufacturer's assistance service).

The thermistors used comply with regulations DIN44081-44082.

If the shaft stops while the tool is still being pushed against the piece being

machined, the spindle bearings may break. If the tool is not immediately moved

away from the piece and the rotation stopped, there is a risk of burning out the

stator.

Power supply 48 V

DC MAX

Current 1.6 A MAX

Switching cycles 10000 Cycles

Contact interruption time < 1 ms

Contact resistance (according to MIL R 5757) < 50 m

Isolation voltage 2 kV

Loading...

Loading...