5 Installation and commissioning

HSD S.p.A. © - h0104k02a.fm091115

33

More useful information on fixing can be found in the appendix A “Technical characteristics”.

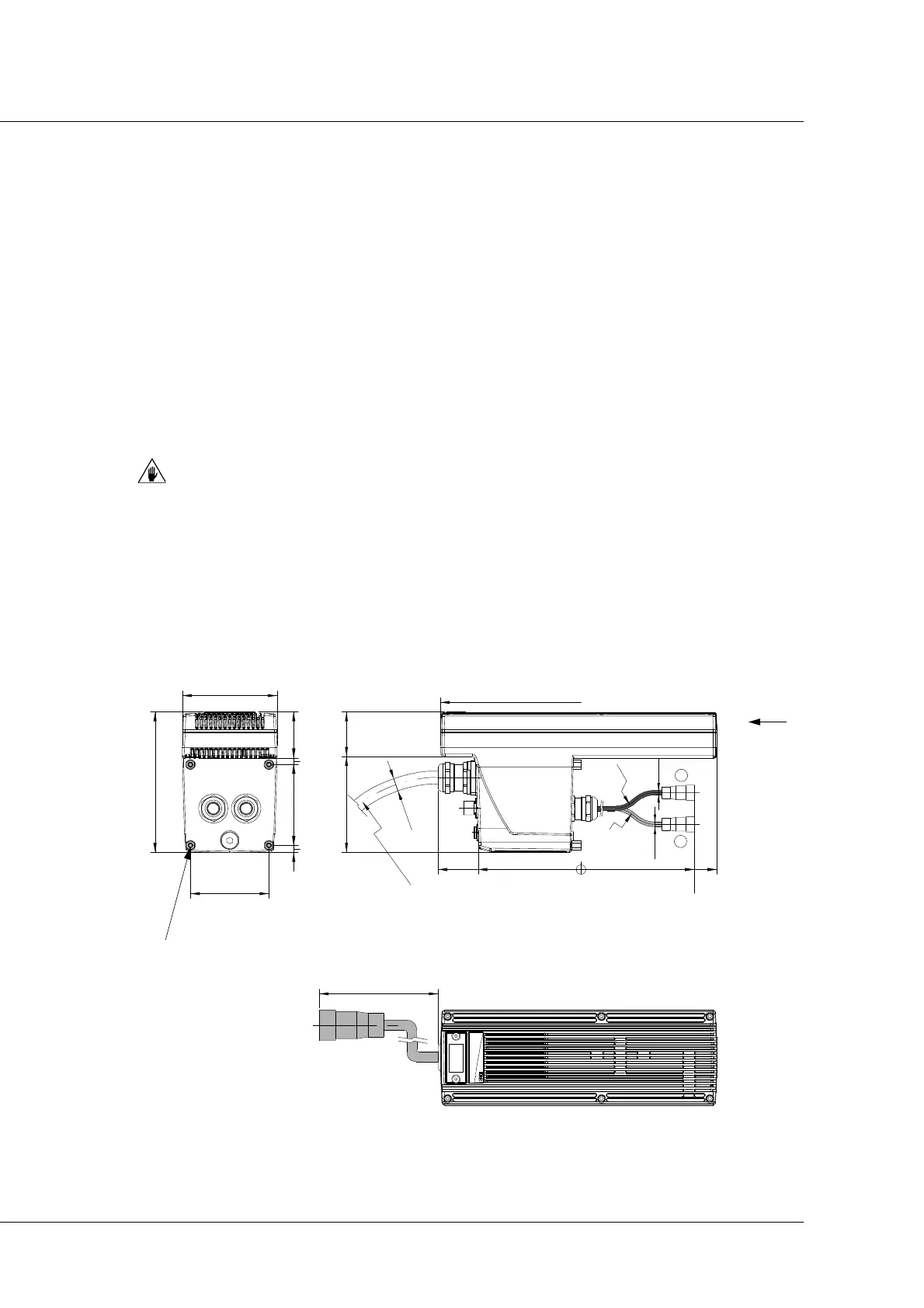

CPH 400 B fixing

To install the electronic drive on the user machine, use the 4 supports/spacers (with screws) on the

corners of the flange housing the outlet cable connections (ref. D on page 25). Use 4 galvanised

M4 screws, minimum strength class 8.8.

Place the drive onto the support surface to which it has to be fixed, in line with the holes

provided;

Fix the drive using n° 4 galvanised M4 screws of suitable length;

Tighten the 4 screws.

In order to ensure the necessary electrical conductivity, use galvanised screws only.

Tightening torque of the screws

M4 screws = 5 Nm

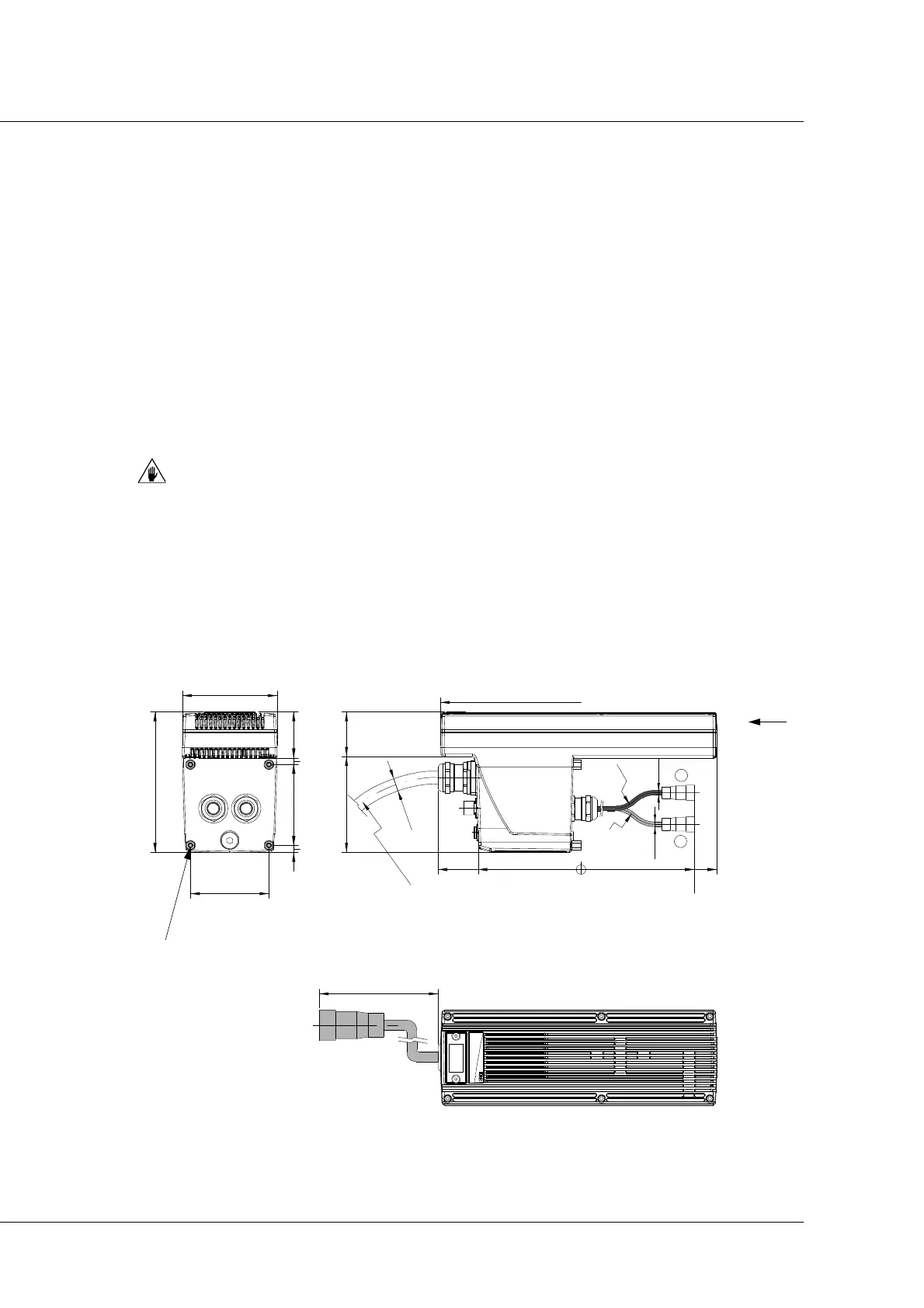

CPH 400 B overall dimensions

More useful information on fixing can be found in the appendix A “Technical characteristics”.

13

14

Rminimo

p. fissa 27,6

p. mob. 55,2

Rminimo

p. fissa 31,2

p. mob. 58,5

1

1

O

R

1

1

0

m

i

n

i

m

o

O7,8

O9,2

67

==

(120)

81

6

69

5,7

39,3

82 38

0 11688122

120

300

C

view from C

M4 x ↧ 4 n°4 holes in the supports/spacers

Loading...

Loading...