6

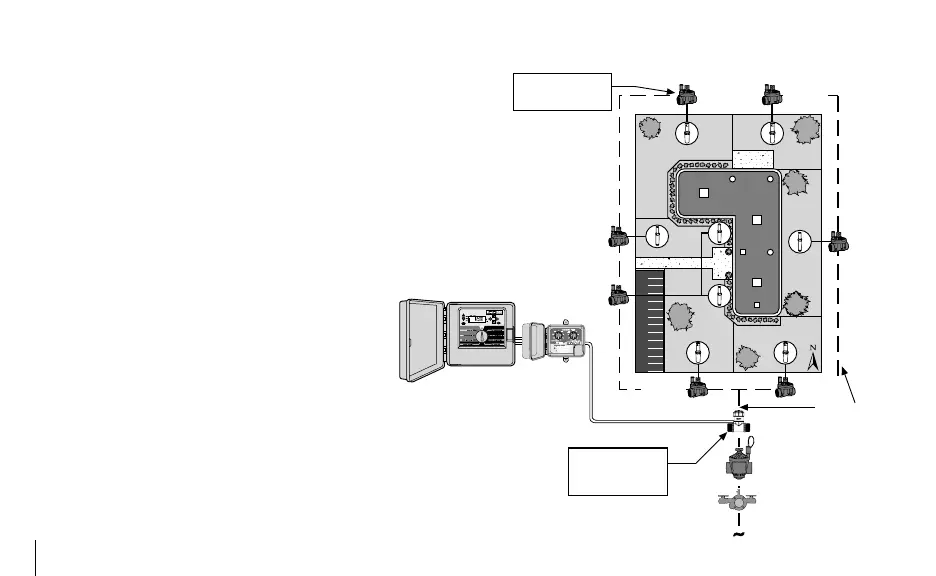

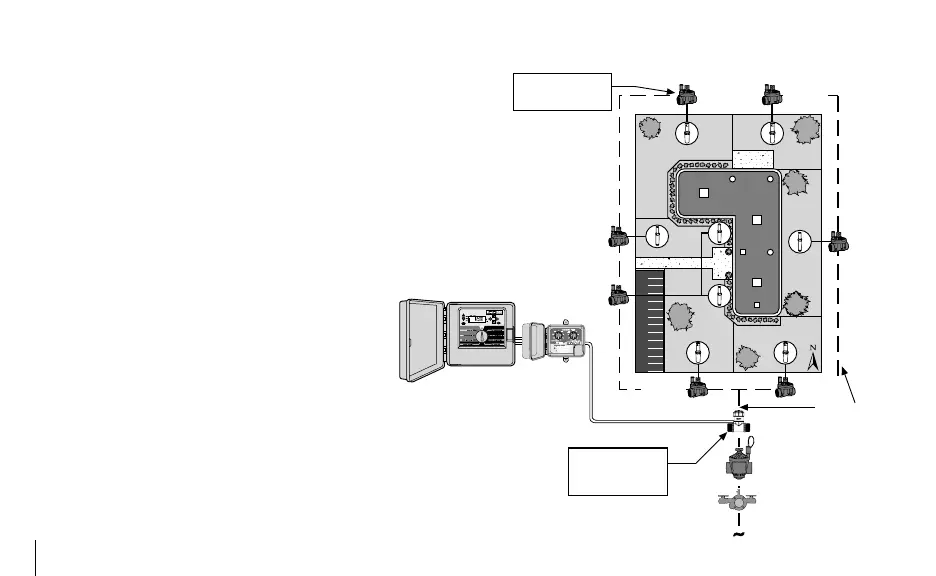

Example of System Operation

In this illustrative example of a small commercial site, the

Flow-Clik sensor is connected to the mainline pipe that

provides water to the system control valves. Because it

is installed immediately down stream of the master valve,

it will provide the added protection of shutting down the

irrigation system if a mainline break should occur.

The Flow-Clik can be set to automatically shut off the

system whenever actual flow within the system exceeds the

flow of the system’s highest flow zone. During installation

of the Flow-Clik, a calibration procedure (see Cali-

brating the Flow-Clik) is used to set the Flow-Clik

at a level of flow dictated by the highest flow zone.

If the system flow exceeds the “calibrated” flow by

a pre-determined amount, the Interface Box will

signal an overflow condition is occurring.

The figure to the right shows an example of an application

using the Flow-Clik sensor. In this example, the valve that

commands the highest flow is valve number 4, which has a

total flow rate of 18.9 gallons per minute (GPM). The user

would turn this valve on and calibrate the Flow-Clik to this

zone. If flow exceeds 18.9 gpm, a signal will be sent to the

Interface Box which would communicate to the controller

SYSTEM OVERVIEW AND FLOW-CLIK OPERATION (continued) ............

ICC Controller

®

® ®

®

®

®

®

®

Flow-Clik Sensor

Master Valve

Back Flow Preventer

Point of Connection

Flow-Clik

Interface

Valve 4 has been

determined to have the

highest flow

Wire

Mainline Pipe

Flow-Clik is located on

mainline to shut down

the system if the

mainline is ruptured

Valve 4

(18.9 GPM)

Valve 6

(17.0 GPM)

Valve 1

(13.0 GPM)

Valve 7

(16.0 GPM)

Valve 2

(14.0 GPM)

Valve 3

(15.0 GPM)

Valve 5

(16.0 GPM)

Loading...

Loading...