Operation Instructions for TCX50 Tire Charger

63

Maintenance Schedule Perform the Following Maintenance

Daily

Drain condensation from pressure regulator

reservoir by pressing in on the tting located on

the bottom of the regulator.

Check for worn or damaged rubber and nylon

components that should be replaced to prevent

damage from occurring. Replace worn parts as

needed (tool supports, rubber pads, lever protector

sleeve and mount/demount head).

Clean all areas that contact rims or tires to prevent

possible scratching to rim.

Weekly

Clean tire changer with shop towels or a vacuum

cleaner. Do not clean with or use compressed

air, which can blast dirt between moving parts.

Do not use cleaning solvents to clean pressure

regulator and oiler (if present).

Periodically

If present, rell oiler using only Hunter Lubri-Oil,

148-133-2, as needed. Petroleum-based oils

should never be used in the oiler and may void

all warranties. Adjust the oiler to release one drop

of oil every three rotations of the clamping table by

adjusting the screw on top.

Check for loose bolts and tighten per

specications.

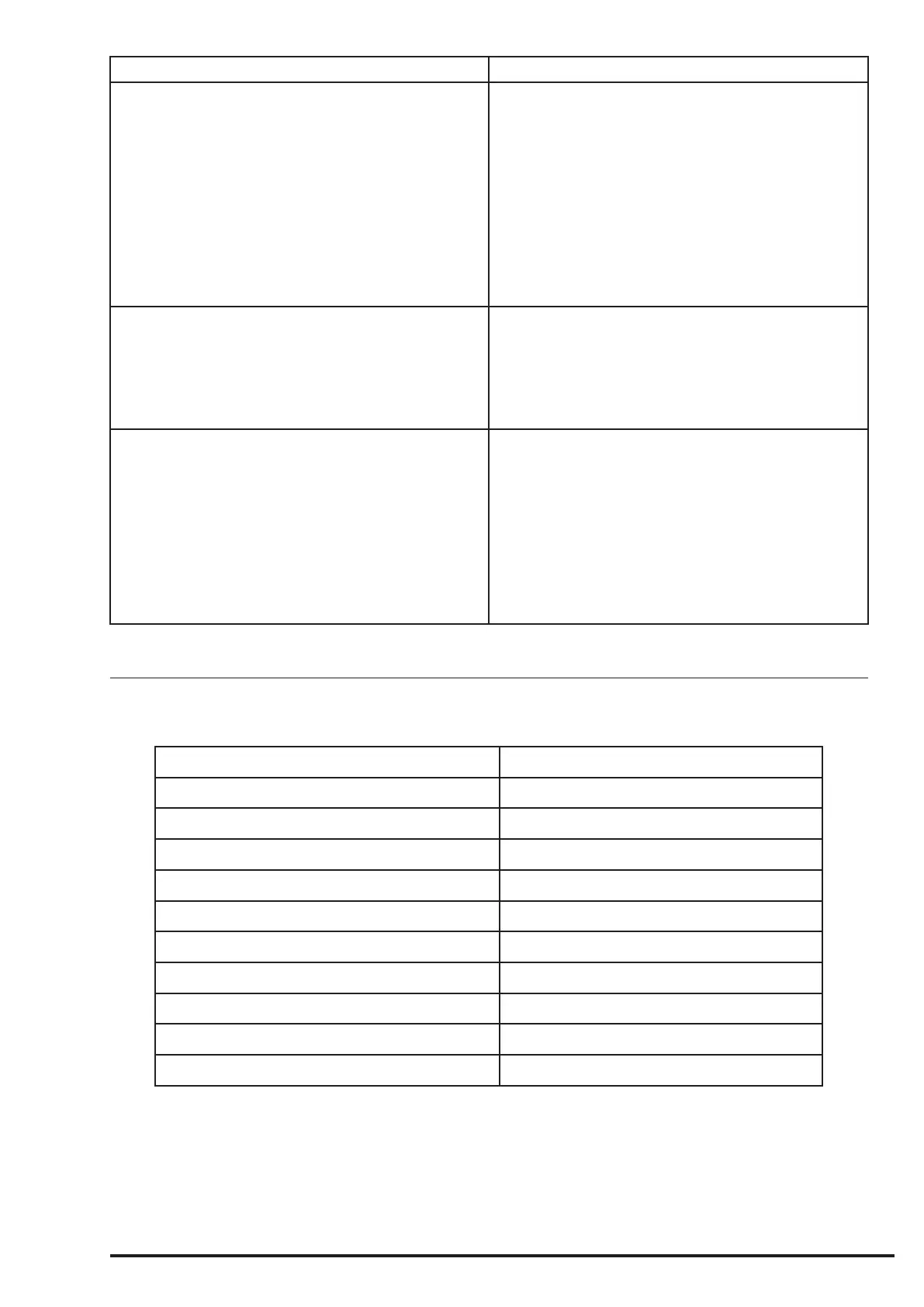

6.2 Maintenance and Replacement Parts

NAME NUMBER

Safety Goggles 179-15-2

Brush RP6-1506

Mounting Paste RP6-3784

Polymer Mount/Demount Head RP11-3314813

Hand Held Bead Lever - straight RP11-3009516

Bead Lever Protector Sleeve (HM) RP6-0326

Bead Lever Protector Sleeve (Std) (4) RP11-8-11400098

High Grip Jaw Protection Kit (2 sets - 8 covers) RP11-8-11100358

Steel Head Inserts (10 sets - 20 covers) RP11-8-11400096

Clamping Jaw Extensions AR46 (4) RP11-8-11400276

Loading...

Loading...