1.3

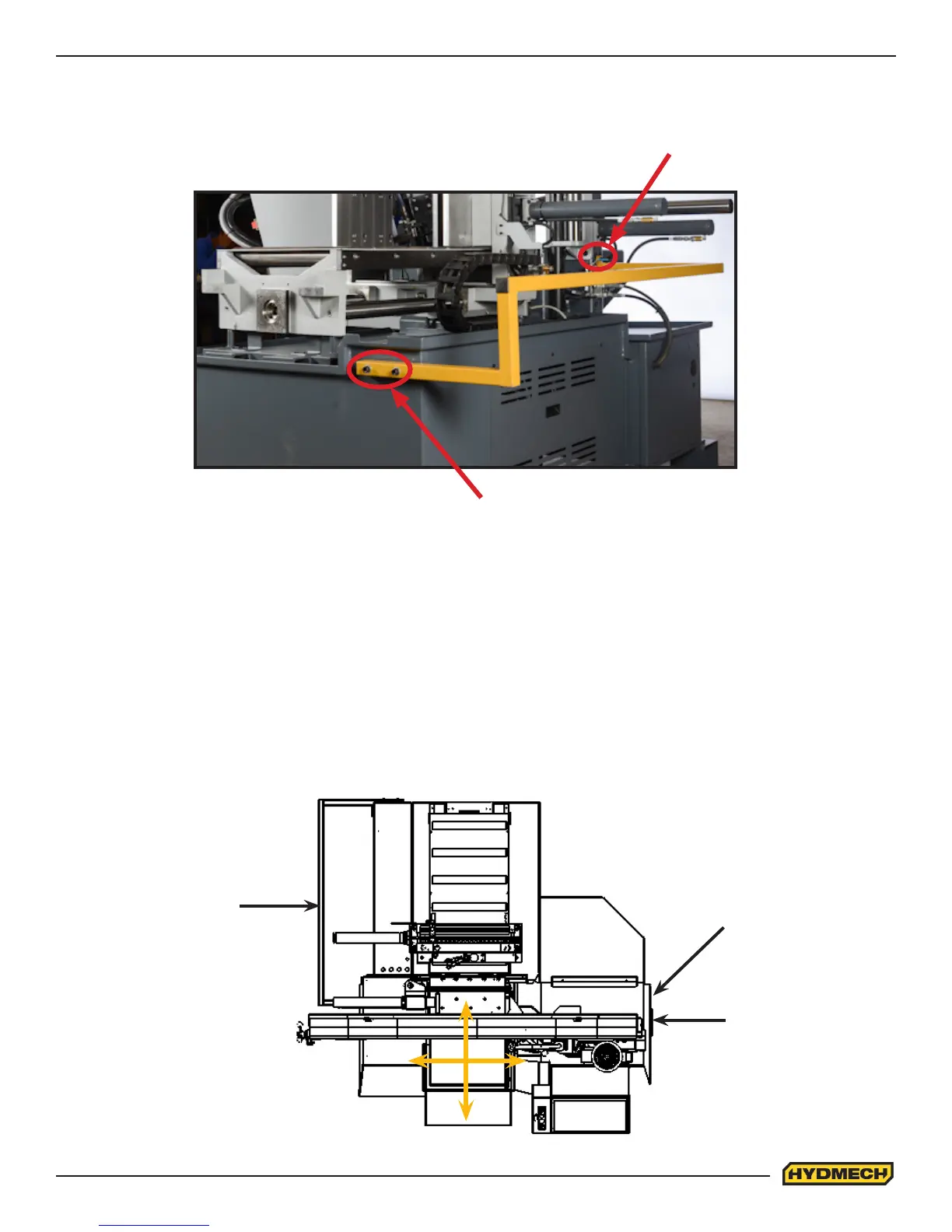

INSTALLATION OF THE SHUTTLE GUARD

The shuttle guard of the S23A has been removed for shipping. This guard must be assembled back on to the machine

before the POWER WIRING CONNECTIONS are completed.

M8 BOLT

M12 BOLTS

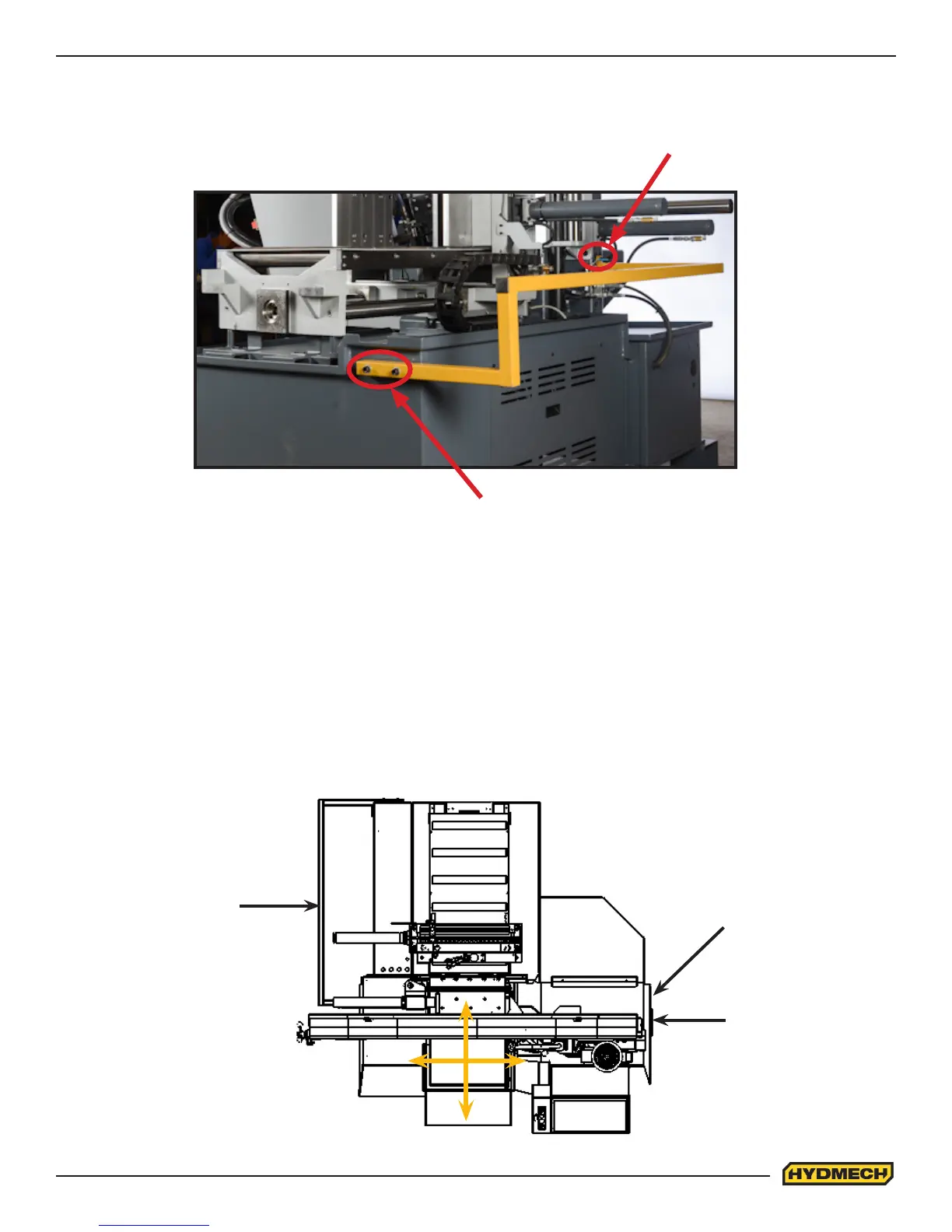

FOUNDATION, LEVELLING AND ANCHORING

Machine location should be carefully selected. A at concrete oor area should be chosen. It should have enough free

space surrounding the machine to enable free access for safe operation and maintenance. The machine should be lev-

eled in both directions (from side to side & from front to back). Six leveling screws used for securing the machine to the

pallet during transport, should be installed, one in each corner of the machine base. It might be required to place steel

plates under leveling bolts to prevent their sinking into the concrete oor. In cases when the machine is to be anchored

permanently, anchoring holes are provided. They are located next to the leveling screw holes. The larger diameter hole

is used for retaining during shipping and for use with concrete oor anchors. The smaller diameter threaded hole at each

corner, are used for leveling the saw.

Using a level on the machine out-feed table, level machine front to back and side to side.

NOTE: In some cases leveling the saw infeed with a slight slope towards the blade is recommended. This will prevent

coolant from running down the raw stock. (This is especially true when cutting tubing or bundles).

SHUTTLE GUARD

COOLANT TANK

DRIVE SIDE

COOLANT COVER

Loading...

Loading...