3.7

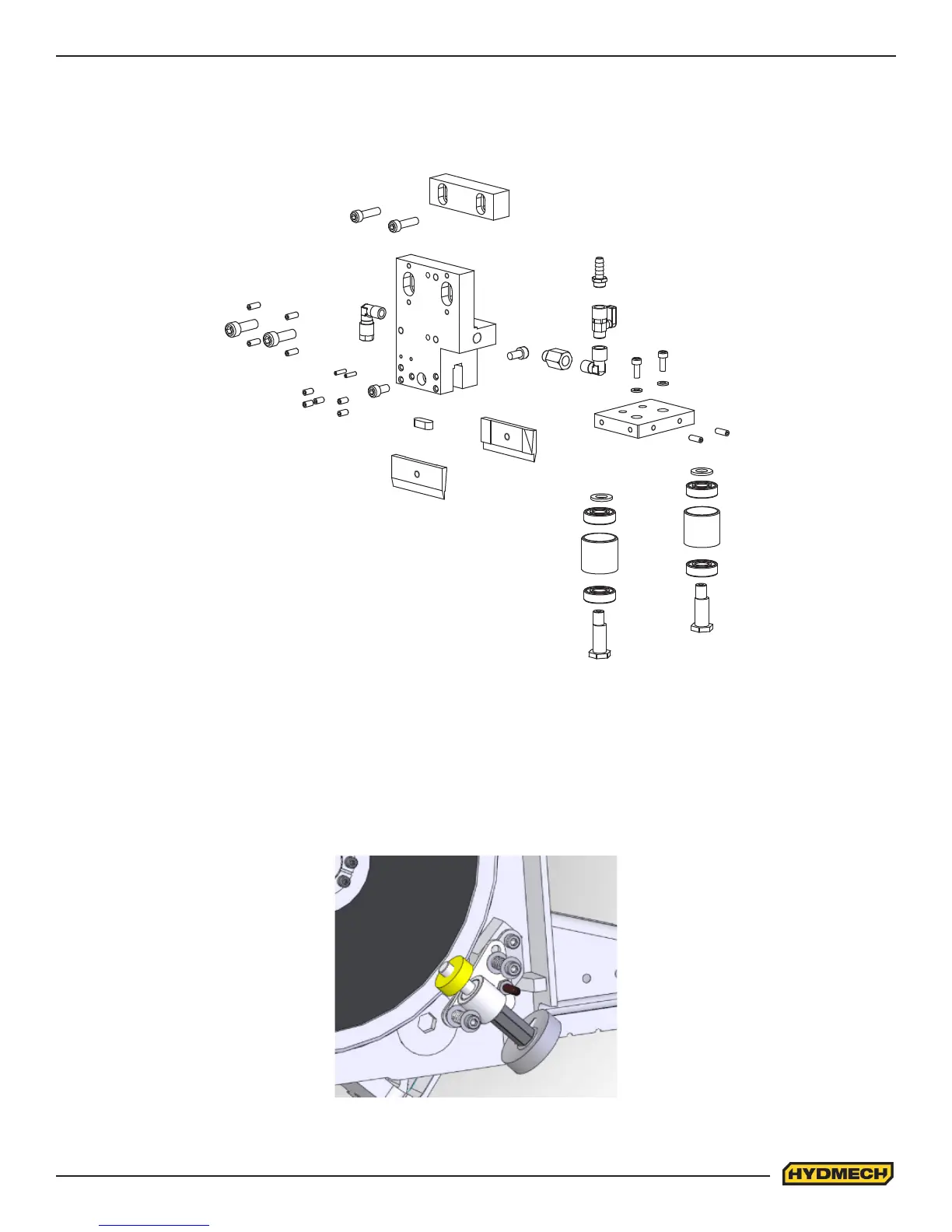

CARBIDE REPLACEMENT

The blade guide blocks are equipped with one top carbide and two side carbide inserts each. They can be replaced by

removing the screws as shown.

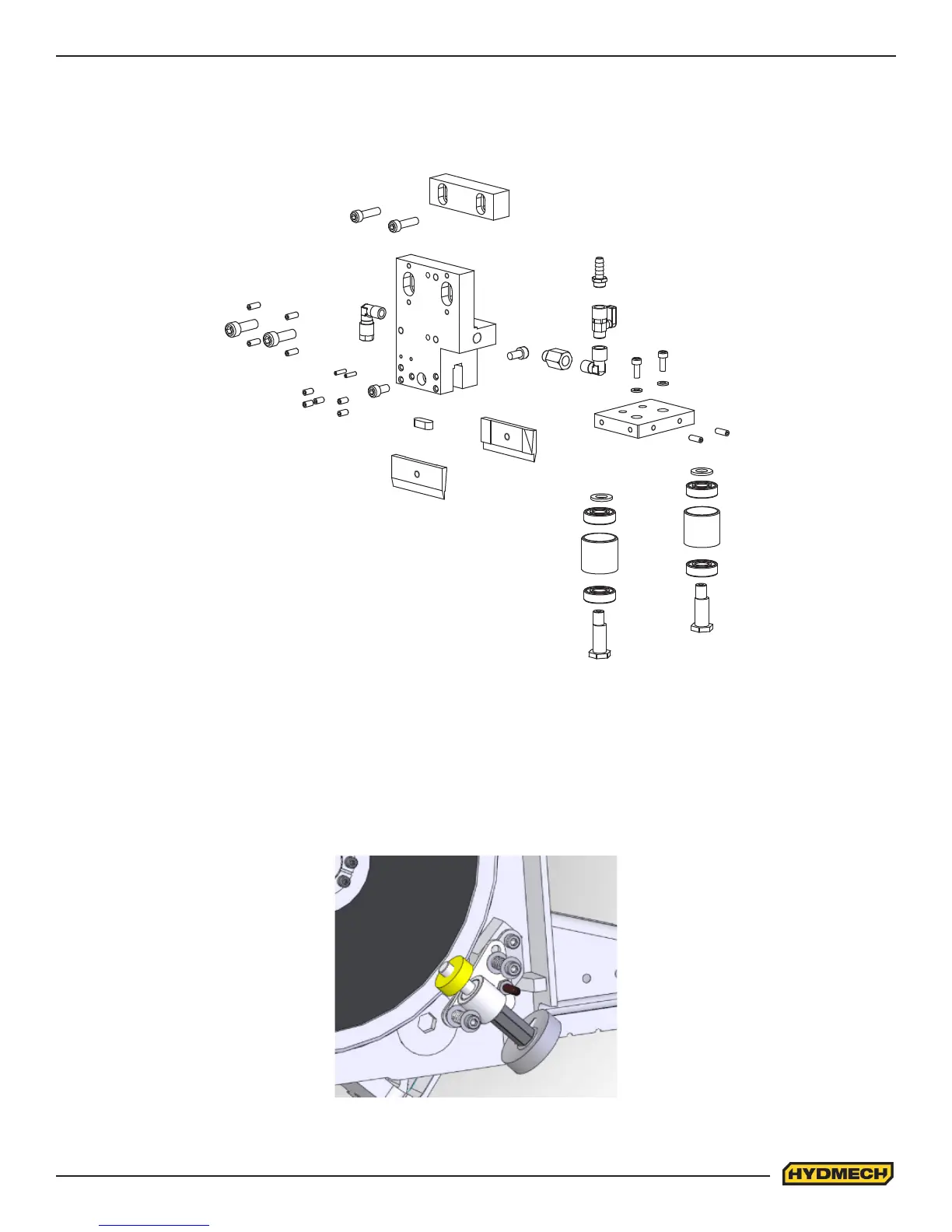

BLADE BRUSH ADJUSTMENT

The machine leaves the factory with the blade brush adjusted for maximum life of the brush. This setting places the ends

of the blade brush wires so as to contact the blade at the bottom of the blade gullets. The plastic drive wheel that is driven

by the drive wheel face should be held against the wheel face with the minimum force that is necessary to ensure brush

rotation. As the blade brush wears it is necessary to periodically adjust it closer to the blade or if a new brush is installed,

further away from the blade.

Loading...

Loading...