2.14

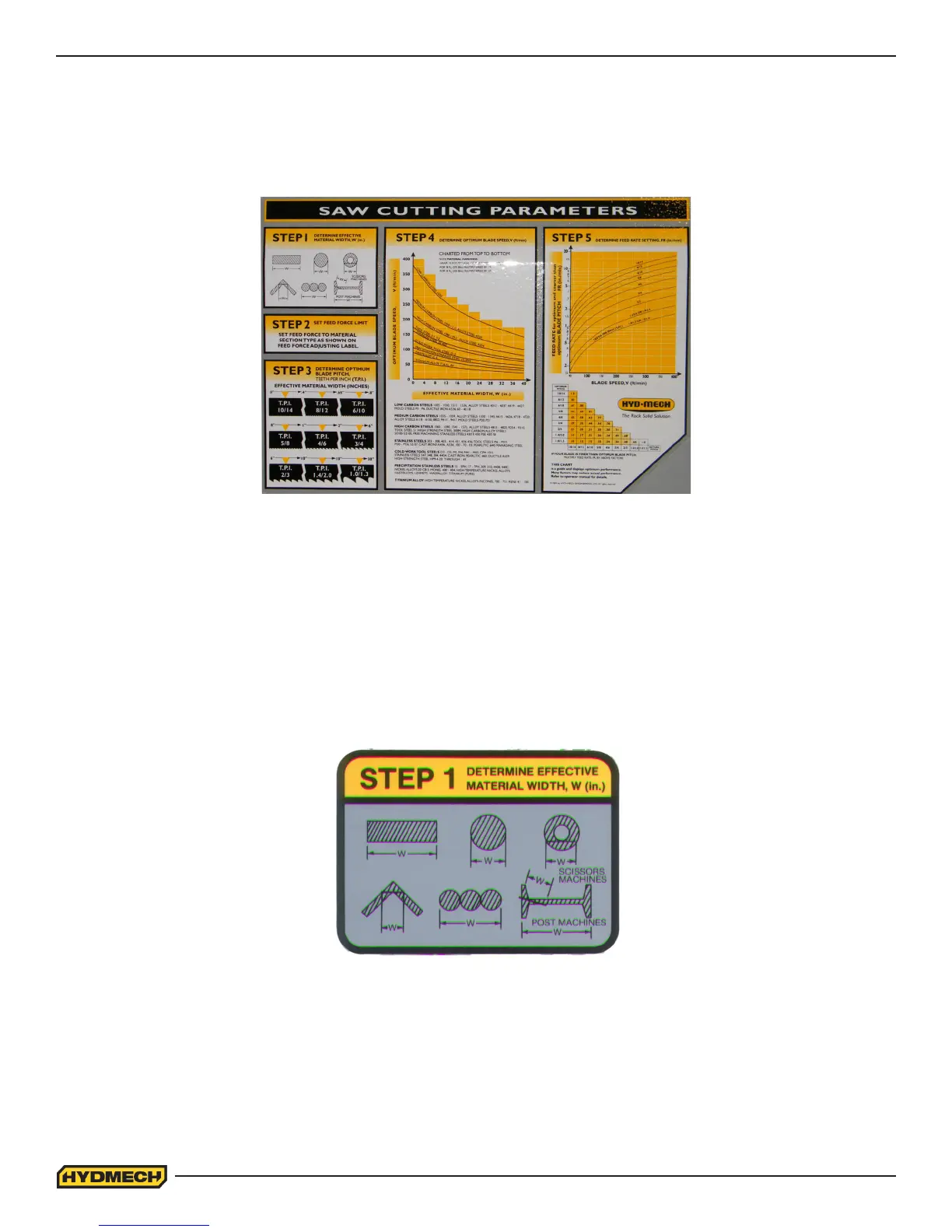

CUTTING PARAMETERS CHART

A full size CUTTING PARAMETERS CHART is mounted on the front of the main electrical panel. The chart contains ve

steps for the operator to follow in order to achieve optimum performance of the saw. These steps are detailed on the

following pages.

Saw Cutting Parameters Chart

CHART EXAMPLE #1

We will use the parameters chart to set up the saw for cutting 8” (200mm) Diameter #1045 Carbon Steel.

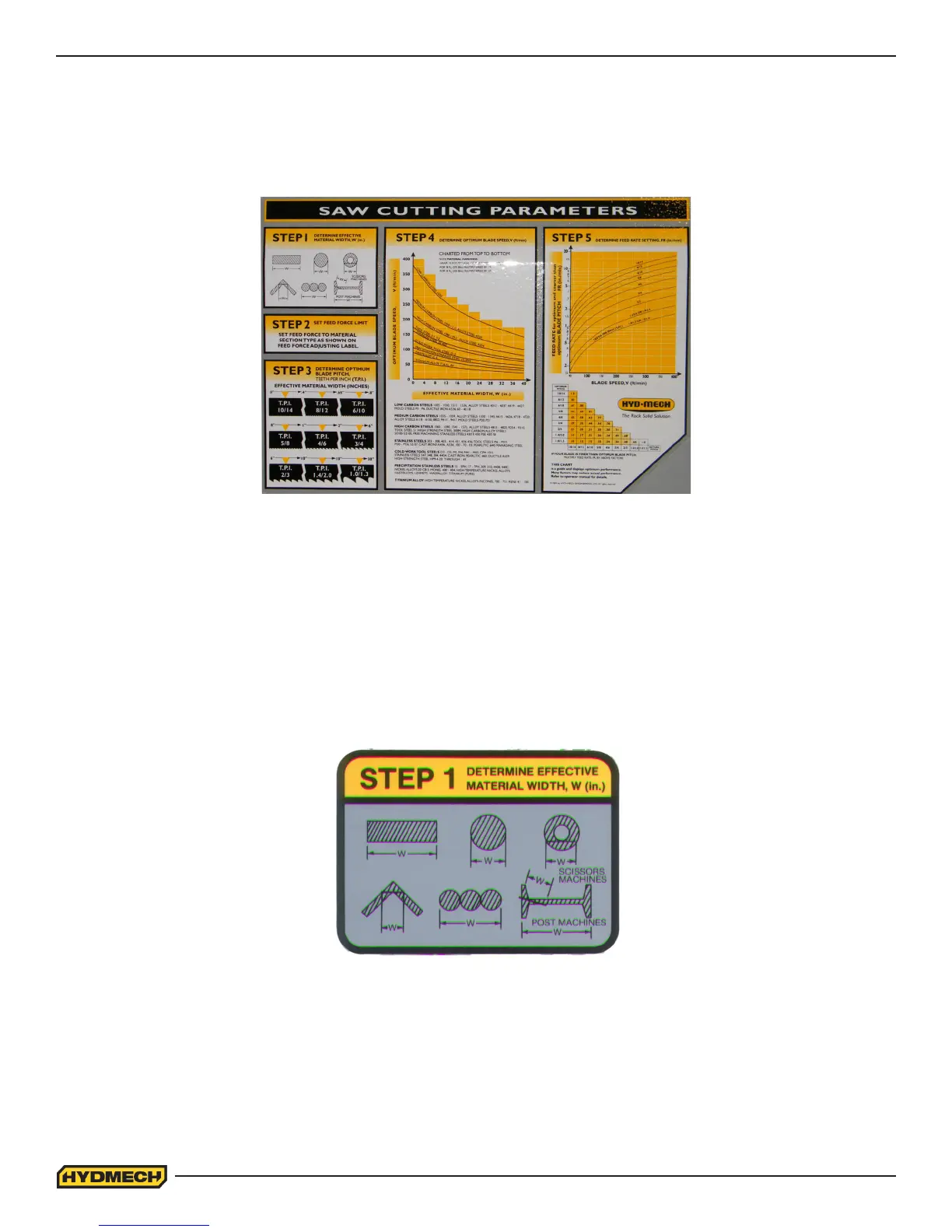

STEP 1: DETERMINE EFFECTIVE MATERIAL WIDTH - W (inches) or (mm)

Eective material width, W (in.) for most common shapes of materials, is the widest solid part of the material to be in

contact with blade during cutting. For simple shapes, as illustrated on the chart, this can be directly measured. For

bundles of tubes and structurals, measuring the eective width is dicult. Eective width is 60% to 75% of the actual

material width.

Material Width Chart

NOTES:

1. Eective material width, as determined here in STEP 1, can be thought of as the maximum width of material

“seen” by each tooth, and it is used in STEPS 3 and 4.

In Example #1, for an 8” (200 mm) diameter solid, Eective Material Width is 8” (200mm).

Loading...

Loading...