2.16

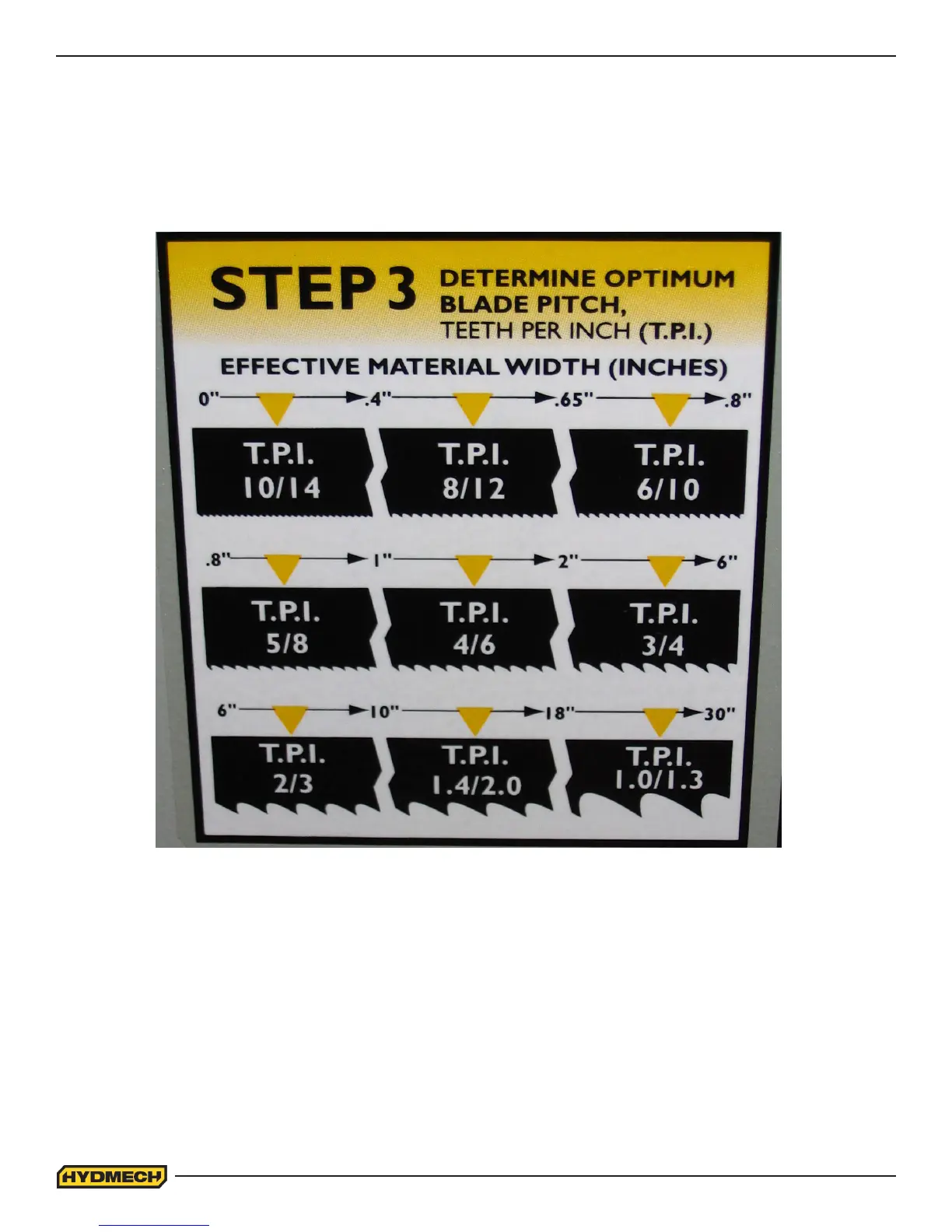

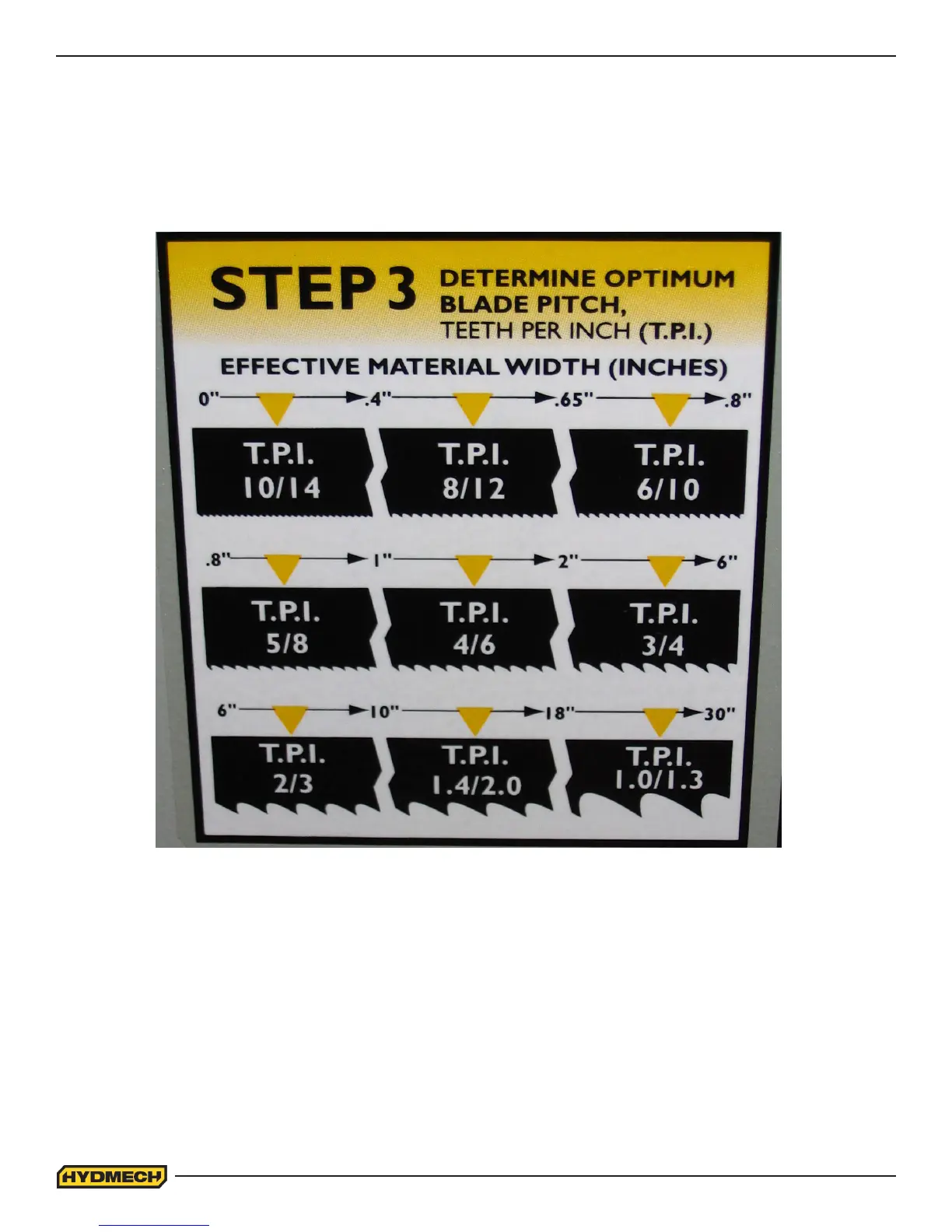

STEP 3: DETERMINE OPTIMUM BLADE PITCH - TEETH PER INCH (T.P.I.)

Selecting a blade with proper tooth pitch is important in order to achieve optimal cutting rates and good blade life.

For cutting narrow or thin wall structural materials a ne blade with many teeth per inch (T.P.I.) is recommended. For wide

materials a blade with a coarse pitch should be used. The sketch can be referenced for the blade pitch changes for

diering eective material widths.

Optimum Blade Pitch (T.P.I) for Material Width (Inches)

It is impractical to change the blade to the proper pitch every time a dierent width of material is cut and it is not

necessary, but remember that the optimum blade will cut most eciently. Too ne a blade must be fed slower on wide

material because the small gullets between the teeth will get packed with chips before they get across and out of the cut.

Too coarse a blade must be fed slower because it has fewer teeth cutting and there is a limit to the depth of a cut taken by

each tooth. Allowance for the use of a non-optimum blade is made in STEP 5.

Example #1: Eective material width of 8” (200 mm):

Optimum blade has 2/3 teeth per inch.

Loading...

Loading...