1.11

HYDRAULIC OIL

The V18 APC bandsaw is supplied with Texaco Rando HD46 oil. If it is necessary to change the oil to a dierent brand it is

good practice to empty the hydraulic tank using a pump. Fill the hydraulic tank approximately 1/3 full with the new brand of

oil and operate the saw through several cycles with maximum cylinder extension. Drain the hydraulic tank again and then

rell to capacity with the new brand.

CUTTING FLUID

As the V18 APC operates with an open reservoir to contain the cutting uid, no cutting uid can be shipped with the saw.

There are two main types of cutting uids available, oil based and synthetic. For oil based uids, the dilution ratio is 1:10,

one part concentrate to ten parts water. For synthetic cutting uids dilution, if required, should be done to the specica-

tions as recommended by the manufacturer.

WIRING CONNECTIONS

After the machine is leveled and anchored the necessary power hook-up needs to be performed. In order to provide safe

operation as well as to prevent potential damage to the machine, only qualied personnel should make the connections.

BEFORE START-UP THE FOLLOWING TWO POINTS SHOULD BE CHECKED

1. Signs of damage that may have occurred during shipping to the electrical cables and the hydraulic hoses.

2. The hydraulic oil level is between the upper and lower levels on the gauge.

As supplied, the machine is set to run on three phase voltage as indicated on the serial plate and voltage label.

During the initial hook-up, it is very important to check that the phase order is correct. This is indicated by the hydraulic

system pressure gauge registering a pressure rise and the blade running in a counter clockwise direction. If the hydraulics

do not register an immediate pressure rise, SHUT THE HYDRAULICS OFF and change the phase order.

ATTENTION: Running the hydraulics “backwards” can damage the hydraulic pump!

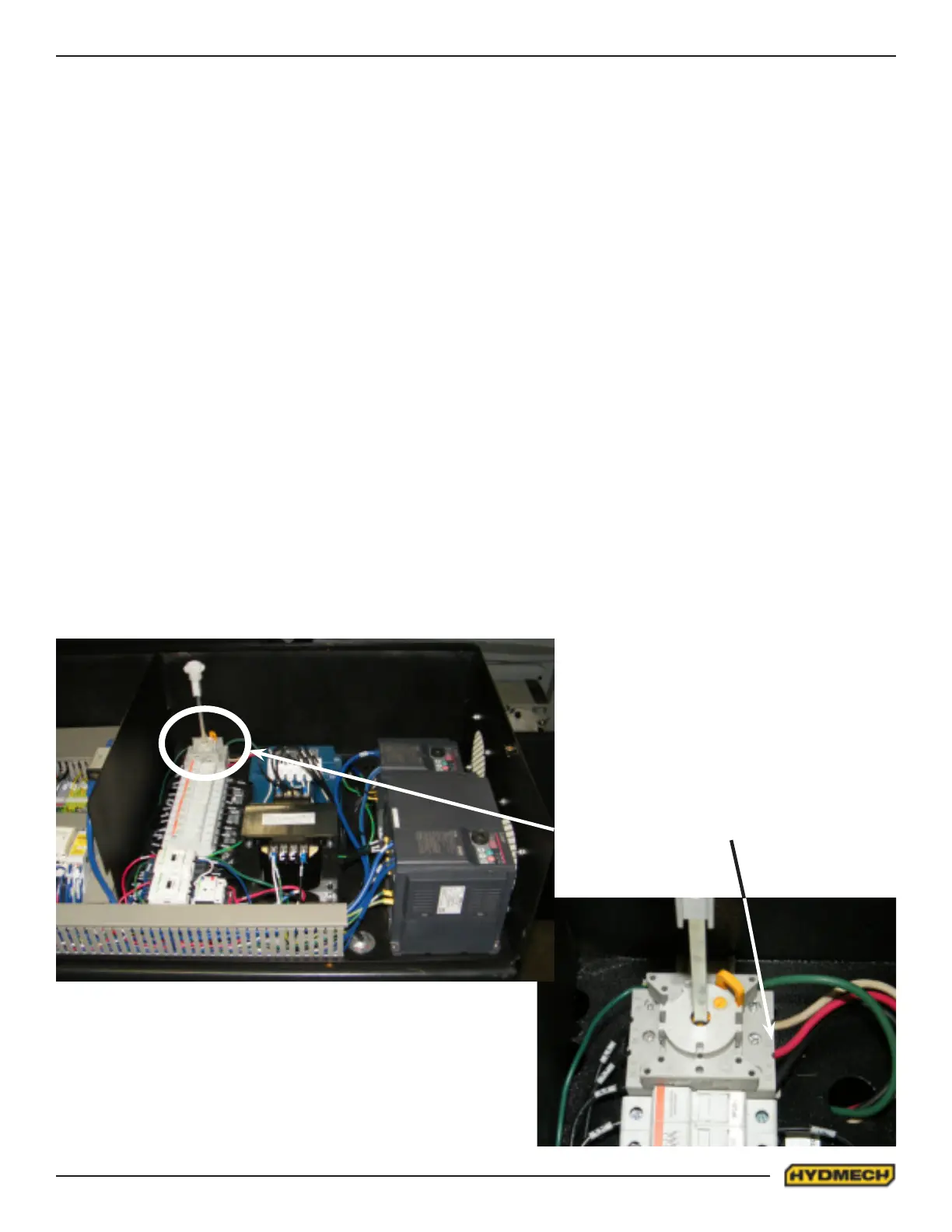

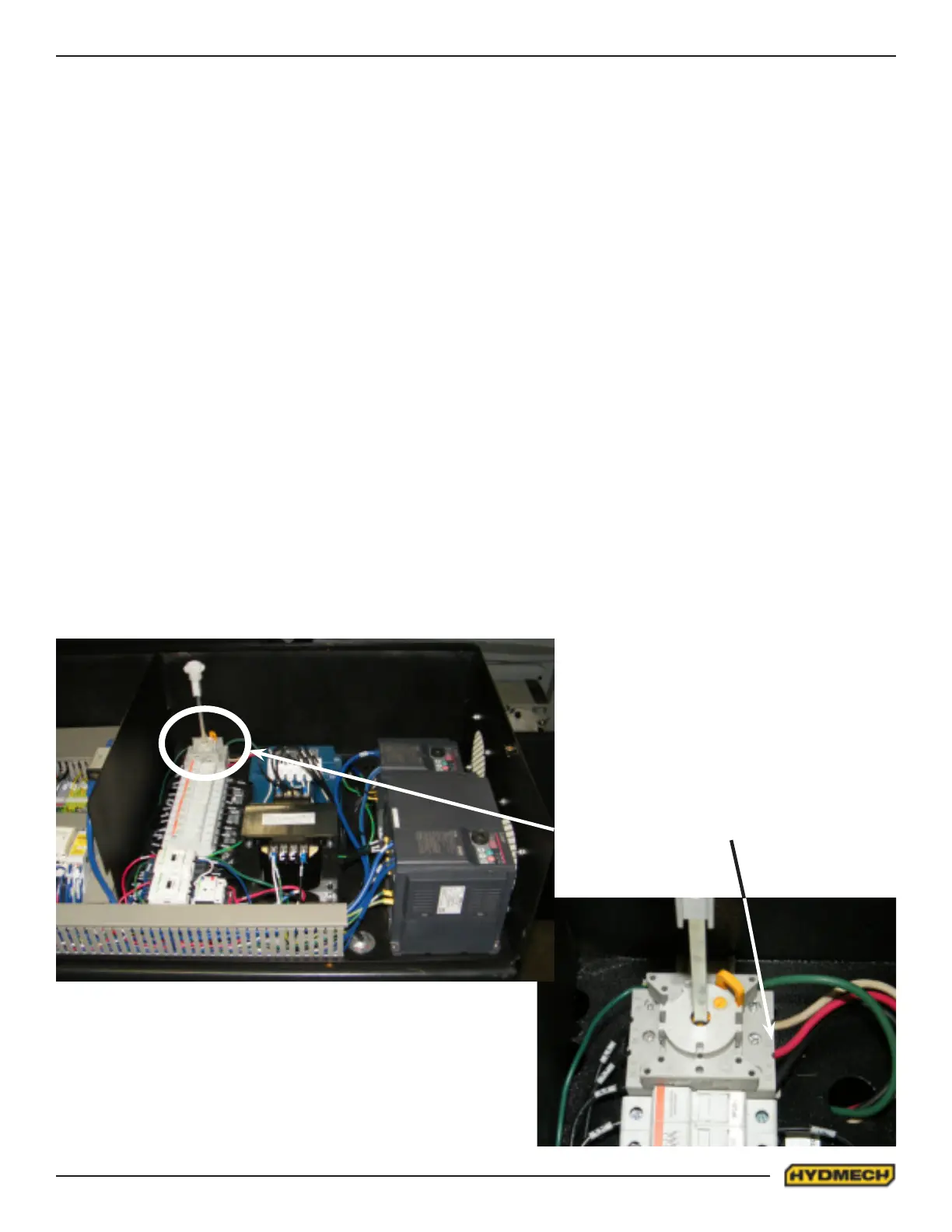

Power connection to the machine is made to the L1, L2, L3 and ground terminals located inside the control panel as

shown in the photo.

L1, L2, L3, G Terminals

Loading...

Loading...