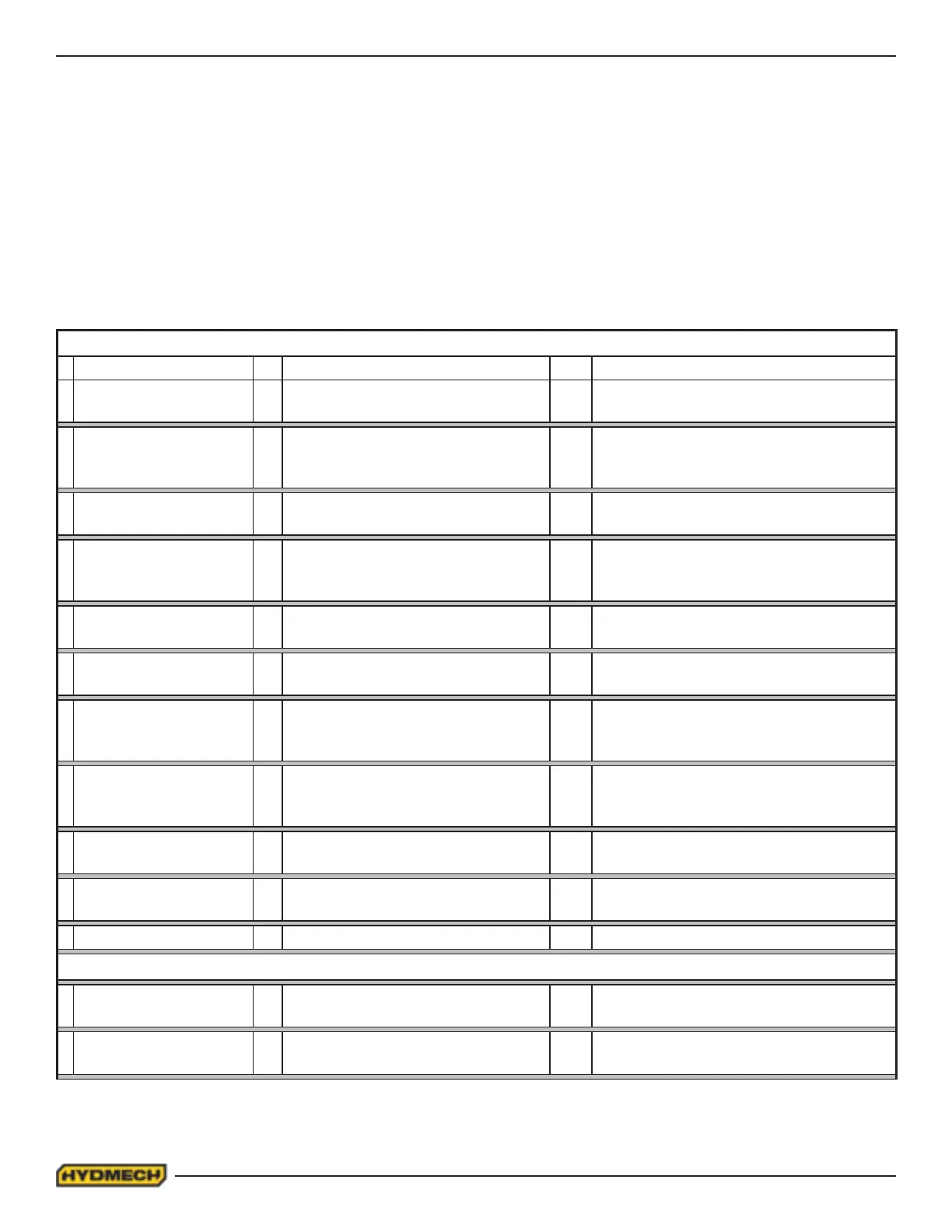

3.8

ELECTRICAL TROUBLESHOOTING

PROBLEMS CAUSE SOLUTION

1 Saw will not start at all. 1a. Motor overload has tripped. 1a.

Depress Blade Motor Overload Reset

Button.

1b. Control circuit has blown. 1b.

Replace Fuse with 8 AMP 250V AG type.

Repeated Fuse Blow-outs indicate an

internal wiring fault.

1d. Safety interlock switch not closed. 1d.

Check that all switches are closed and

operating properly.

2

Saw will start, but no

hydraulic functions

respond

2a.

Check system pressure gauge. Wrong

phase order if no pressure.

2a.

Stop immediately. Reverse any two of

three phase connections.

2b.

If pumps runs noisily then checkthe

hydraulic oil level at gauge.

2b.

Stop immediately and add hydraulic oil until

the correct level is present.

2c.

Check the pump/motor coupling for

separation.

2c.

Stop immediately and check for the

adjustment required.

3

Functions will not

respond to manual

controls.

3a.

Check pilots of valves. If pilot fails to

light, then check electrical system.

3a-b.

The solution to this problem is handled best

by a qualied technician.

3b.

If pilot lights but output fails the coil

may be bad. Check dirt in valve

spool.

4

An operator control will

not respond.

4

The switch or pushbutton contact

assembly is defective.

4

Replace the component that is inoperative.

Test voltage levels at switch.

5

Hydraulics run but blade

will not start.

5a. Check for red fault light at VFD. 5a.

Interrupt main supply to machine for two to

three minutes.

5b. Red fault light on VFD is not on. 5b. Check blade motor line fuses.

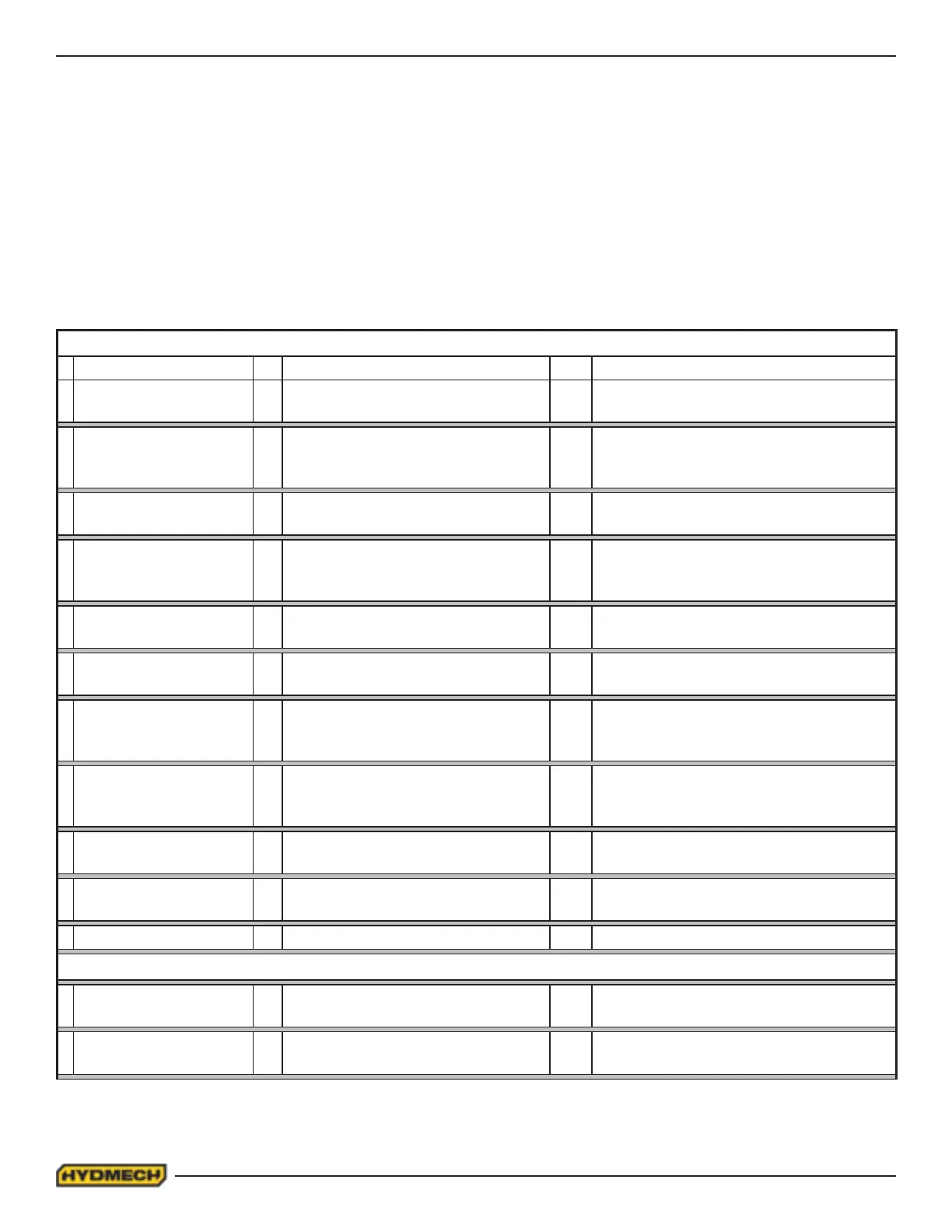

CUTTING AND BLADE TROUBLESHOOTING

1

Saw is cutting out of

square.

1a. Blade is worn. 1a.

Change the blade and check alignment with

new blade.

1b. Blade guide is worn or not adjusted. 1b.

Replace the worn guide or adjust the guide

until the blade is cutting square.

TROUBLE SHOOTING GUIDE

Most problems which may occur have one of the relatively simple solutions which appear in this section. If the solution is

not found here, contact the Hyd·Mech Distributor from whom you purchased your bandsaw. They have trained eld ser-

vice personnel who will be able to rectify the problem.

NOTES:

1. IF THE BLADE IS RUNNING COUNTER CLOCKWISE OR THE HYDRAULIC PUMP IS NOISY SHUT THE SAW

DOWN IMMEDIATELY!

2. If the drive motor is to be replaced, it must be replaced with a non-vented motor to prevent coolant leaking into the

motor.

Loading...

Loading...