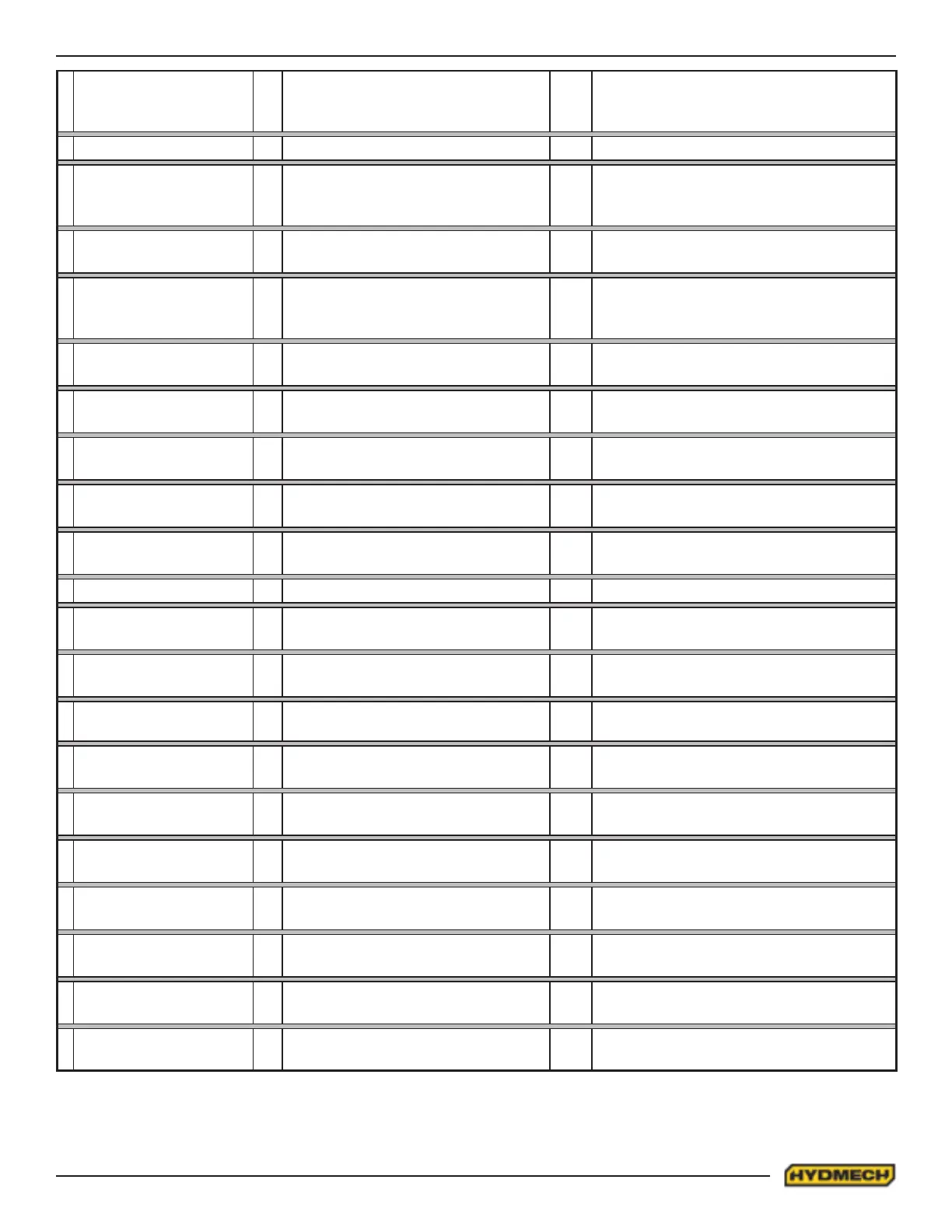

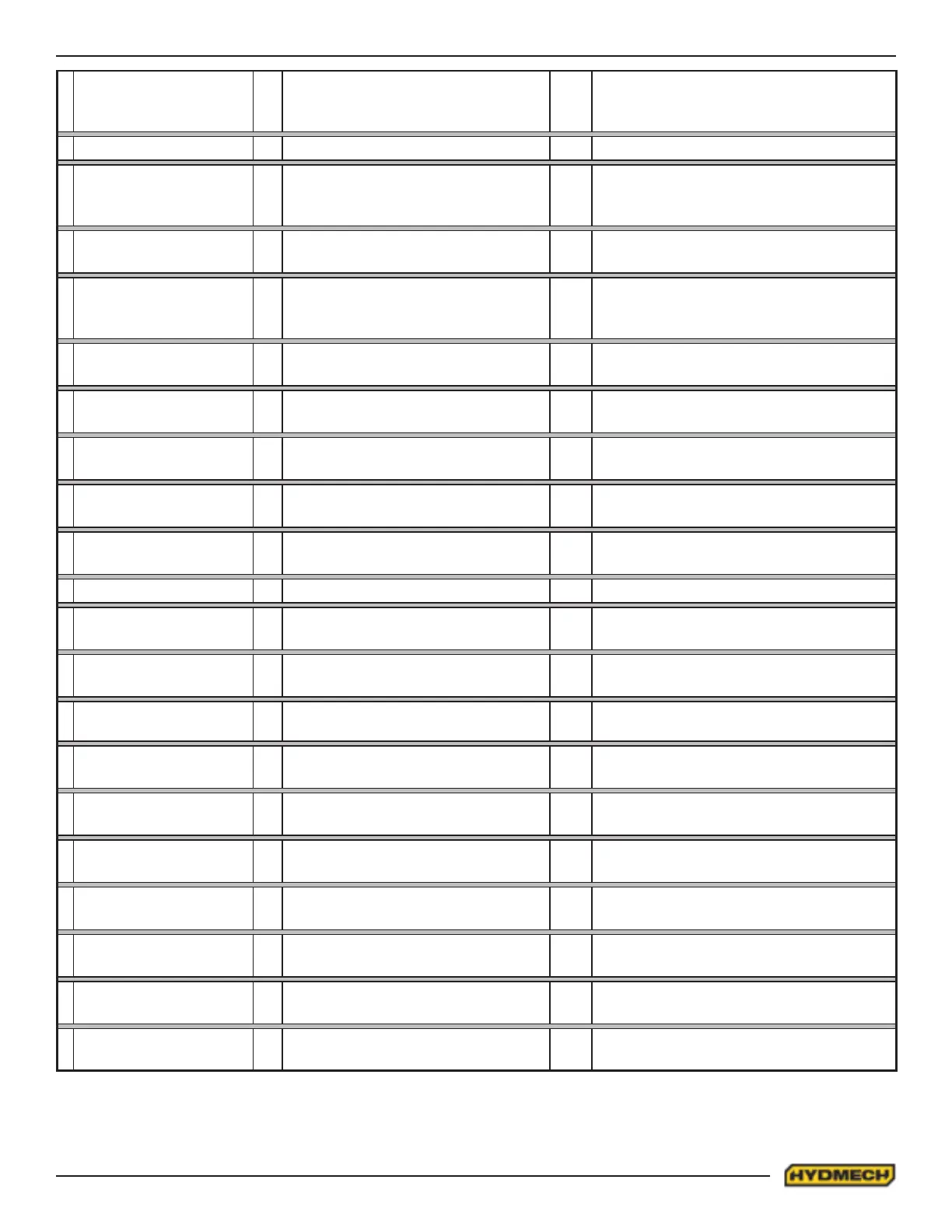

3.9

2 Blade comes o wheels. 2a. Blade tension is insucient. 2a.

Blade tension is determined by system

pressure. Check. (Extended head, check if

blade tension gauge reads 650 psi).

2b. Blade tracking out of adjustment. 2b. Have tracking set to blade specication.

3 Blade stalls while cutting. 3a. Blade tension is insucient. 3a.

Blade tension is determined by system

pressure. Check. (Extended head, check if

blade tension gauge reads 650 psi).

3b. Excessive feed force. 3b.

Reduce the Feed Force pressure and

attempt cut.

4

Blade vibrates

excessively.

4a. Blade tension is insucient. 4a.

Blade tension is determined by system

pressure. Check. (Extended head, check if

blade tension gauge reads 650 psi).

4b. Blade speed excessive. 4b.

Reduce the blade speed to eliminate

vibration.

4c. Guide arms too far apart. 4c.

Adjust the distance between the guide arms

(Min.)

5

Excessive blade

breakage.

5a. Excessive feed rate. 5a.

Reduce the feed rate and check system

pressure.

5b. Excessive blade tension. 5b.

Blade tension is determined by system

pressure. Check.

6 Tooth strippage. 6a. Blade pitch is too ne. 6a.

Select a blade with a coarser pitch for

cutting.

6b. Blade brush is not cleaning. 6b. Replace or adjust the blade brush.

6c. Excessive feed rate. 6c.

Reduce the feed rate. Check calculations

for rate.

6d. Excessive feed force. 6d.

Reduce the feed force pressure maximum

setting.

7 No coolant ow. 7a. Coolant reservoir low or empty. 7a. A coolant to the reservoir. Check for leaks.

7b. Coolant line is blocked. 7b.

Use compressed air to blow obstruction out

of the line.

7c. Coolant pump not operating. 7c.

Check the pump output and replace if

necessary.

8 Head will not advance. 8a. The feed rate valve is closed. 8a.

Pointer is at “0”. Turn the Feed Rate Knob

counter clockwise to open.

8b. The Feed Force limit is too low. 8b.

Increase the Feed Force limit - to at least

100 PSI.

8c. Pointer out of adjustment. 8c.

Loosen pointer lock nut. Turn the knob

clockwise to “0”. Tighten lock nut.

9

Head advances with feed

at “0”.

9a. Pointer stopped but valve open. 9a.

Loosen pointer lock nut. Turn the knob

clockwise to “9”. Tighten lock nut.

9b. Fast Approach is open. Blocked lever. 9b.

Adjust Fast Approach lever. Phone factory

for details.

Loading...

Loading...