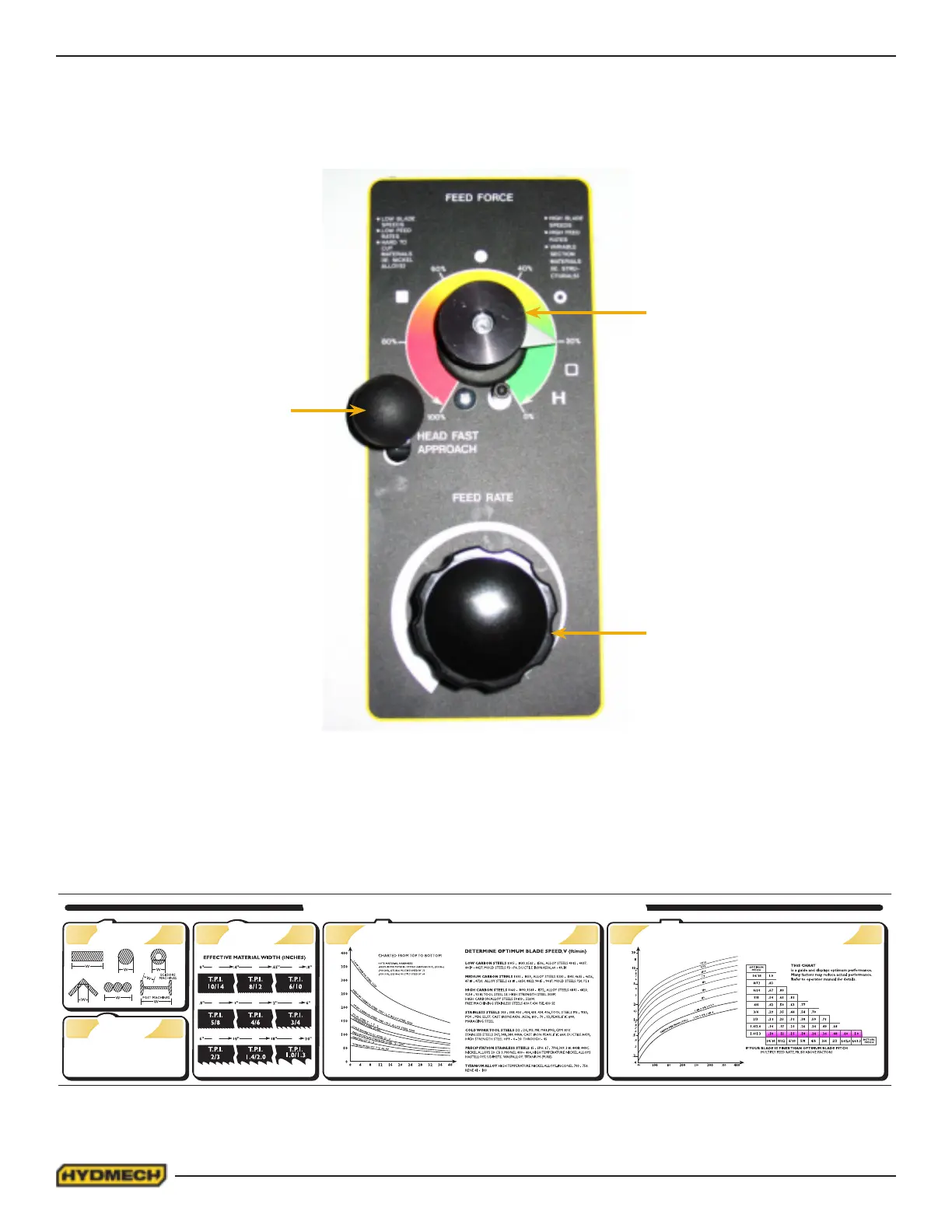

The Hydraulic Feed Control is located next to the control panel. These controls allow independent control of Feed Force

and Feed Rate.

decrease).

Depress for fast head approach.

STEP

4

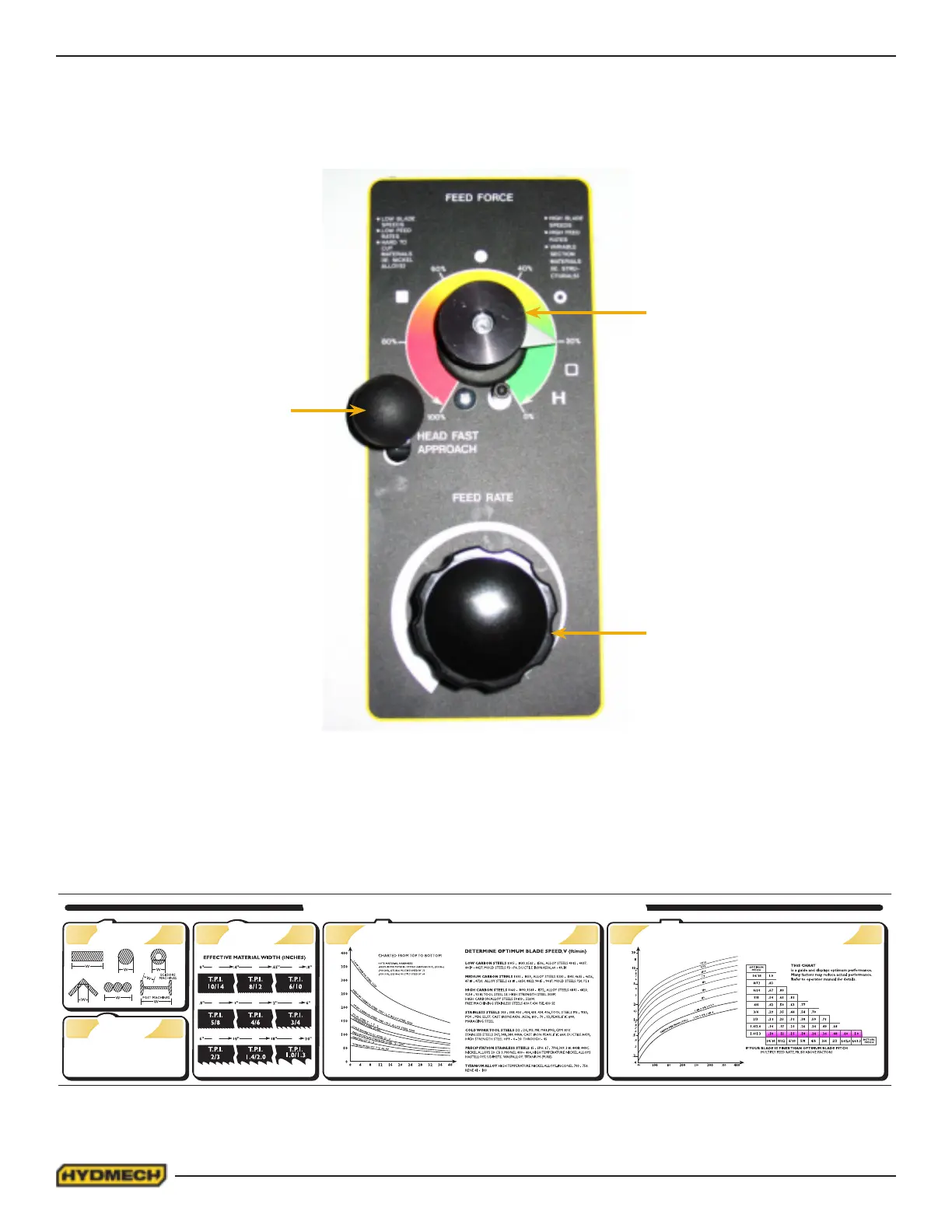

DETERMINE OPTIMUM BLADE SPEED, V (ft/min)

STEP

DETERMINE FEED RATE SETTING, FR (in./min)

51

STEP

DETERMINE EFFECTIVE

MATERIAL WIDTH, W (in.)

SET FEED FORCE LIMIT

SET FEED FORCE TO MATERIAL

SECTION TYPE AS SHOWN ON

FEED FORCE ADJUSTING LABEL.

2

STEP

DETERMINE OPTIMUM

BLADE PITCH,

TEETH PER INCH (T.P.I.)

3

STEP

SAW CUTTING PARAMETERS

exported as an eps

EFFECTIVE MATERIAL WIDTH, w(in.)

OPTIMUM BLADE SPEED, v(ft/min)

FEED RATE for optimum & coarser than

optimum BLADE PITCH FR (in./min)

BLADE SPEED, V (ft/min)

STEP

4

DETERMINE OPTIMUM BLADE SPEED, V (ft/min)

STEP

DETERMINE FEED RATE SETTING, FR (in./min)

51

STEP

DETERMINE EFFECTIVE

MATERIAL WIDTH, W (in.)

SET FEED FORCE LIMIT

SET FEED FORCE TO MATERIAL

SECTION TYPE AS SHOWN ON

FEED FORCE ADJUSTING LABEL.

2

STEP

DETERMINE OPTIMUM

BLADE PITCH,

TEETH PER INCH (T.P.I.)

3

STEP

SAW CUTTING PARAMETERS

EFFECTIVE MATERIAL WIDTH, w(in.)

OPTIMUM BLADE SPEED, v(ft/min)

FEED RATE for optimum & coarser than

optimum BLADE PITCH FR (in./min)

BLADE SPEED, V (ft/min)

S25-9-25B

LOGO REMOVED MARCH 31/2014

392540

29.50”

6.75”

STEP

4

DETERMINE OPTIMUM BLADE SPEED, V (ft/min)

STEP

DETERMINE FEED RATE SETTING, FR (in./min)

51

STEP

DETERMINE EFFECTIVE

MATERIAL WIDTH, W (in.)

SET FEED FORCE LIMIT

SET FEED FORCE TO MATERIAL

SECTION TYPE AS SHOWN ON

FEED FORCE ADJUSTING LABEL.

2

STEP

DETERMINE OPTIMUM

BLADE PITCH,

TEETH PER INCH (T.P.I.)

3

STEP

SAW CUTTING PARAMETERS

EFFECTIVE MATERIAL WIDTH, w(in.)

OPTIMUM BLADE SPEED, v(ft/min)

FEED RATE for optimum & coarser than

optimum BLADE PITCH FR (in./min)

BLADE SPEED, V (ft/min)

STEP

4

DETERMINE OPTIMUM BLADE SPEED, V (ft/min)

STEP

DETERMINE FEED RATE SETTING, FR (in./min)

51

STEP

DETERMINE EFFECTIVE

MATERIAL WIDTH, W (in.)

SET FEED FORCE LIMIT

SET FEED FORCE TO MATERIAL

SECTION TYPE AS SHOWN ON

FEED FORCE ADJUSTING LABEL.

2

STEP

DETERMINE OPTIMUM

BLADE PITCH,

TEETH PER INCH (T.P.I.)

3

STEP

SAW CUTTING PARAMETERS

EFFECTIVE MATERIAL WIDTH, w(in.)

OPTIMUM BLADE SPEED, v(ft/min)

FEED RATE for optimum & coarser than

optimum BLADE PITCH FR (in./min)

BLADE SPEED, V (ft/min)

S25-9-25B392540

29.50”

6.75”

Loading...

Loading...