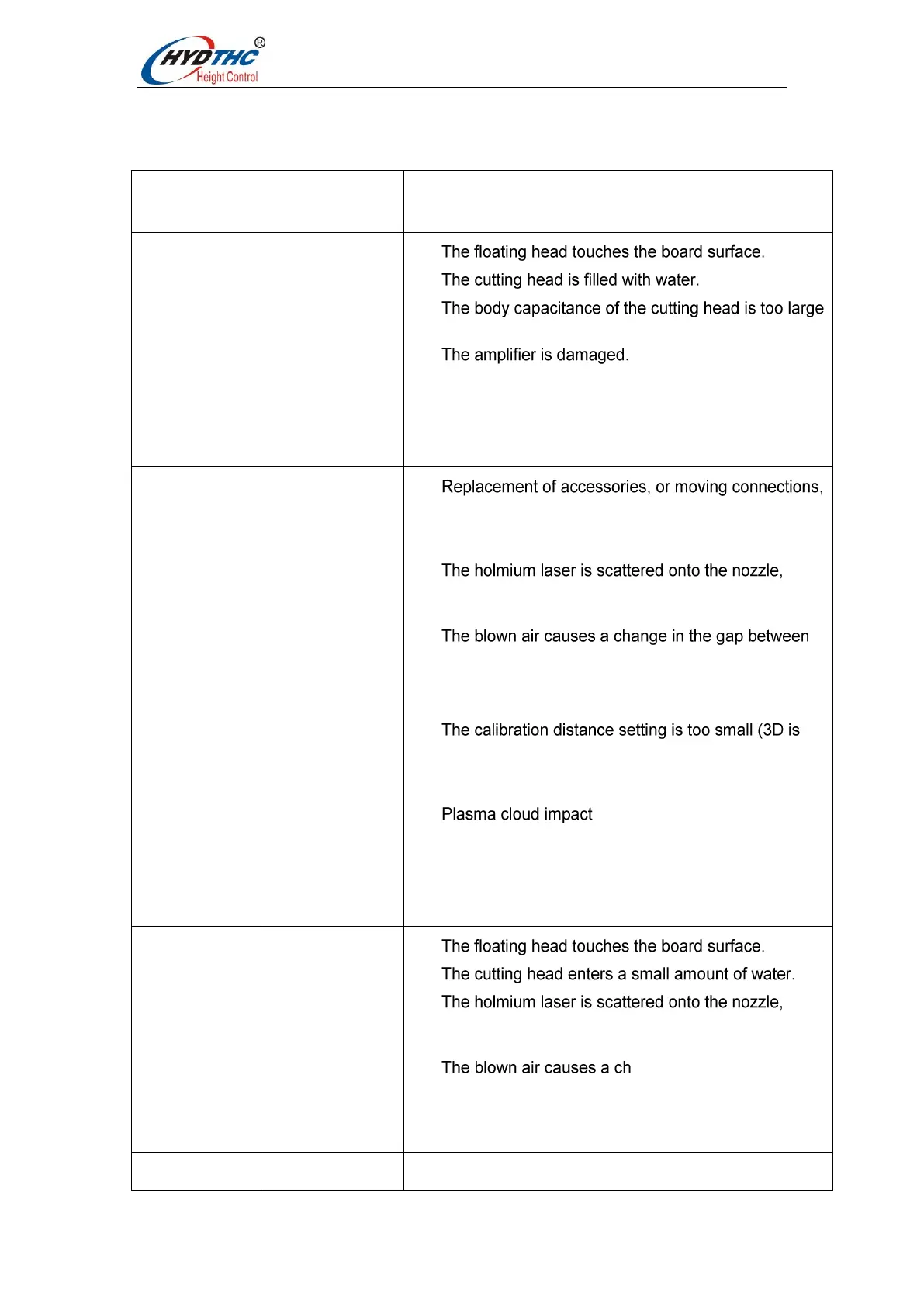

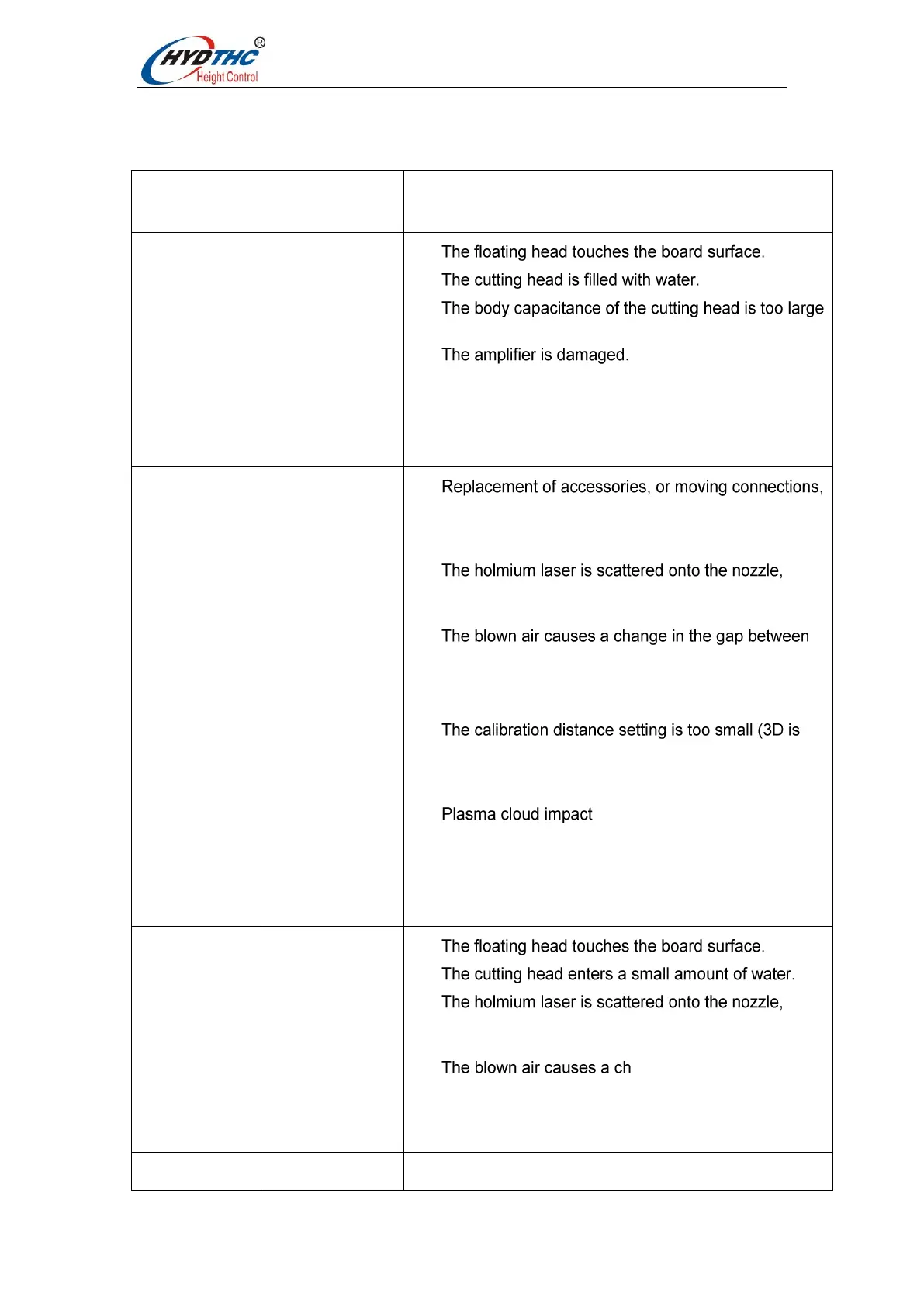

and is outside the detection range.

Connection is not fixed.

In the internal of cutting head, the positive of

capacity (spray) is short circle

with the negative of capacity (the shell of machine).

or random changes in the characteristics of the analog

components themselves may also cause this alarm.

Recalibrate is ok.

causing the nozzle temperature to rise sharply, resulting

in a temperature drift.

the positive electrode (nozzle) and the negative

electrode (the cutting head outer box).

Connection is not fixed.

less than 10mm, 2D is less than 15mm), and it may

cause an alarm that the body capacitance becomes

small.

capacitor amplifier. In the

cutting process of stainless steel plates, especially filmed

stainless steel plates, the following height should not be

set below 0.5mm, and the appropriate increase of the

following height will be improved; the blowing air

pressure is appropriately increased.

causing the nozzle temperature to rise sharply, resulting

in a temperature drift.

ange in the gap between

the positive electrode (nozzle) and the negative

electrode (the cutting head outer box).

Loading...

Loading...