宏宇达数控 & 弘宇达智能

地址:深圳市南山区中山园路 1001 号 E4-6C(TCL 国际 E 城)

TEL:0755-26625800 FAX:0755-26729960 -3-

1.Brief introduction

1.1 Introduction

CHC-1000S capacitance height controller(Hereinafter referred to as CHC-1000S). In

the laser cutting process, the distance between the nozzle and the surface of the

workpiece is not constant due to factors such as uneven workpiece and cutting high-

pressure air jet, which will have a negative effect on the cutting effect and may even

crash the nozzle. CHC-1000S can keep the distance between the nozzle and the

workpiece surface constant during high-speed laser cutting, protect the nozzle from

colliding with the workpiece, and greatly improve the cutting effect. The capacitance

sensor on the cutting head can detect the distance from the nozzle to the surface of the

workpiece, and send it to the adjustment box for processing through the preamplifier. The

output signal is sent to the servo controller to control the Z axis.

CHC-1000S can be used as a controller to output the voltage, or as a distance

measurement system to output the distance signal, it depends on the selected mode:

sensor control mode or distance measurement system mode.

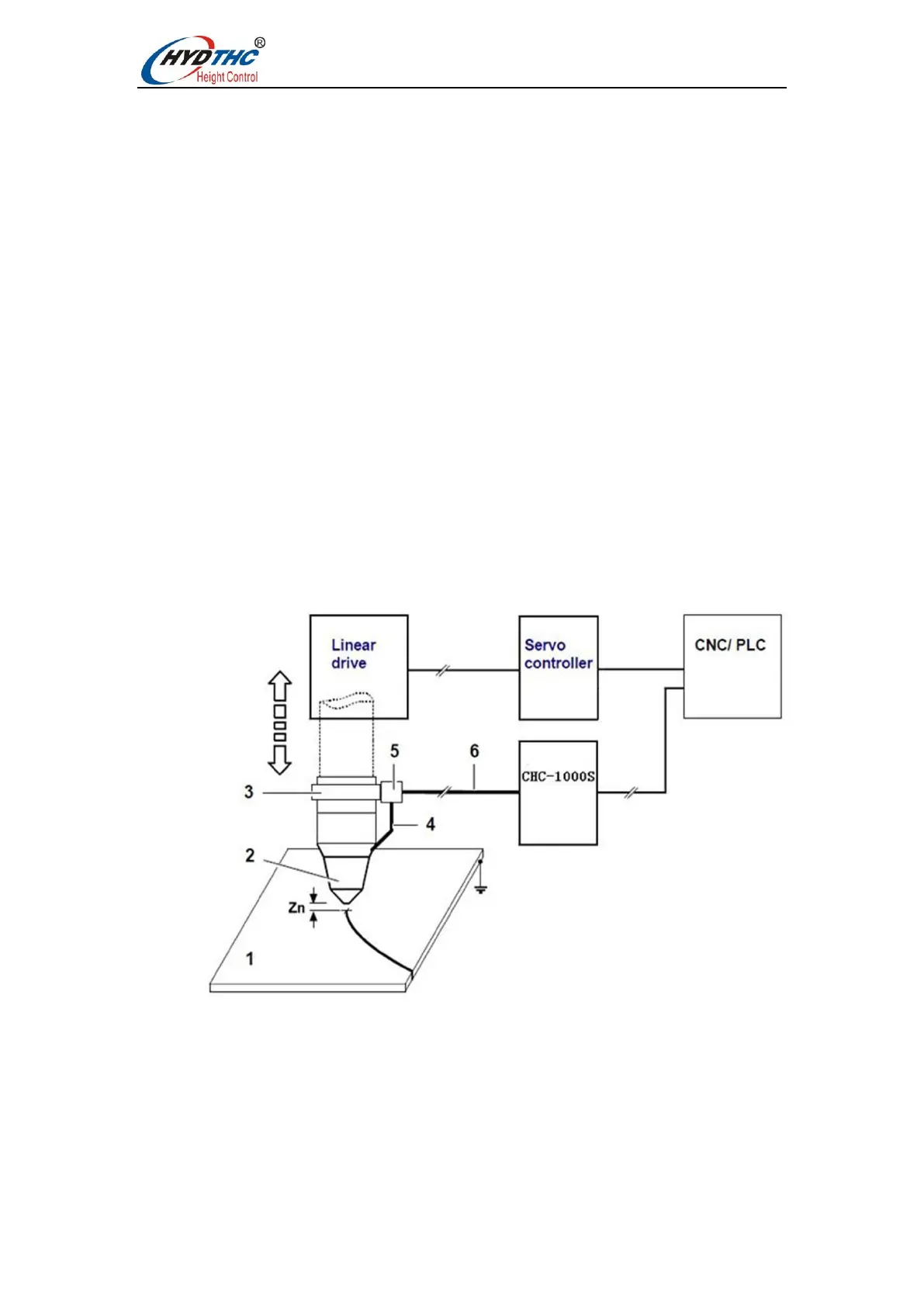

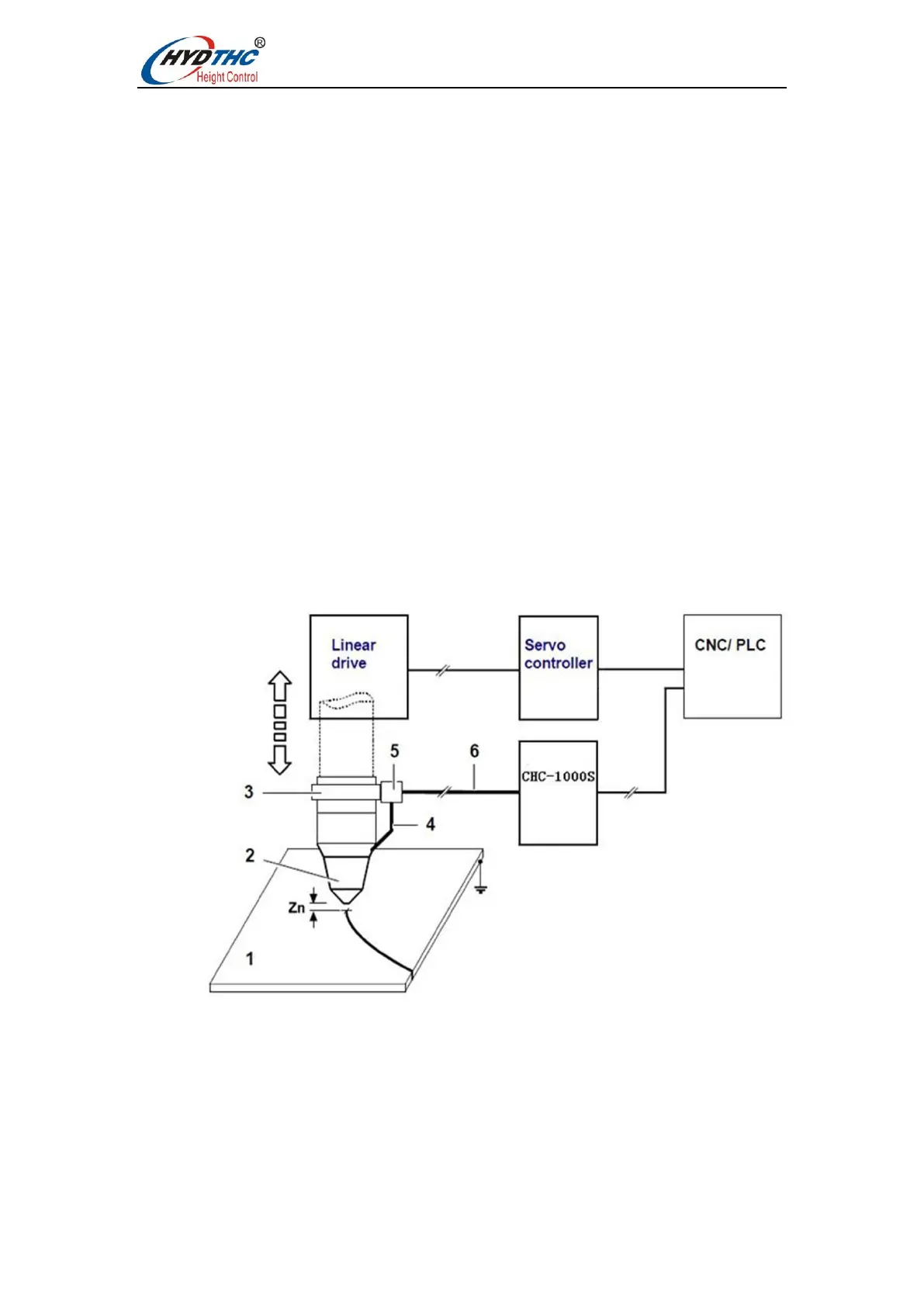

1-1. system diagram

1 workpiece 4 electrode cable

2 sensor 5 preamplifier

3 laser head 6 sensor cable

Loading...

Loading...