TORCH SETUP

powermax

45

Operator Manual 3-29

Accessing raw arc voltage

If you should need to access raw arc voltage, contact your Hypertherm distributor or authorized

Hypertherm repair facility for assistance.

WARNING:

HIGH VOLTAGE AND CURRENT

Connecting directly to the plasma circuit for access to raw arc voltage

increases the risk of shock hazard, energy hazard, and fire hazard in the

event of a single fault. The output voltage and the output current of the

circuit are specified on the data plate.

Refer to the following table when connecting the Powermax45 to a torch height controller or CNC

controller with a machine interface cable.

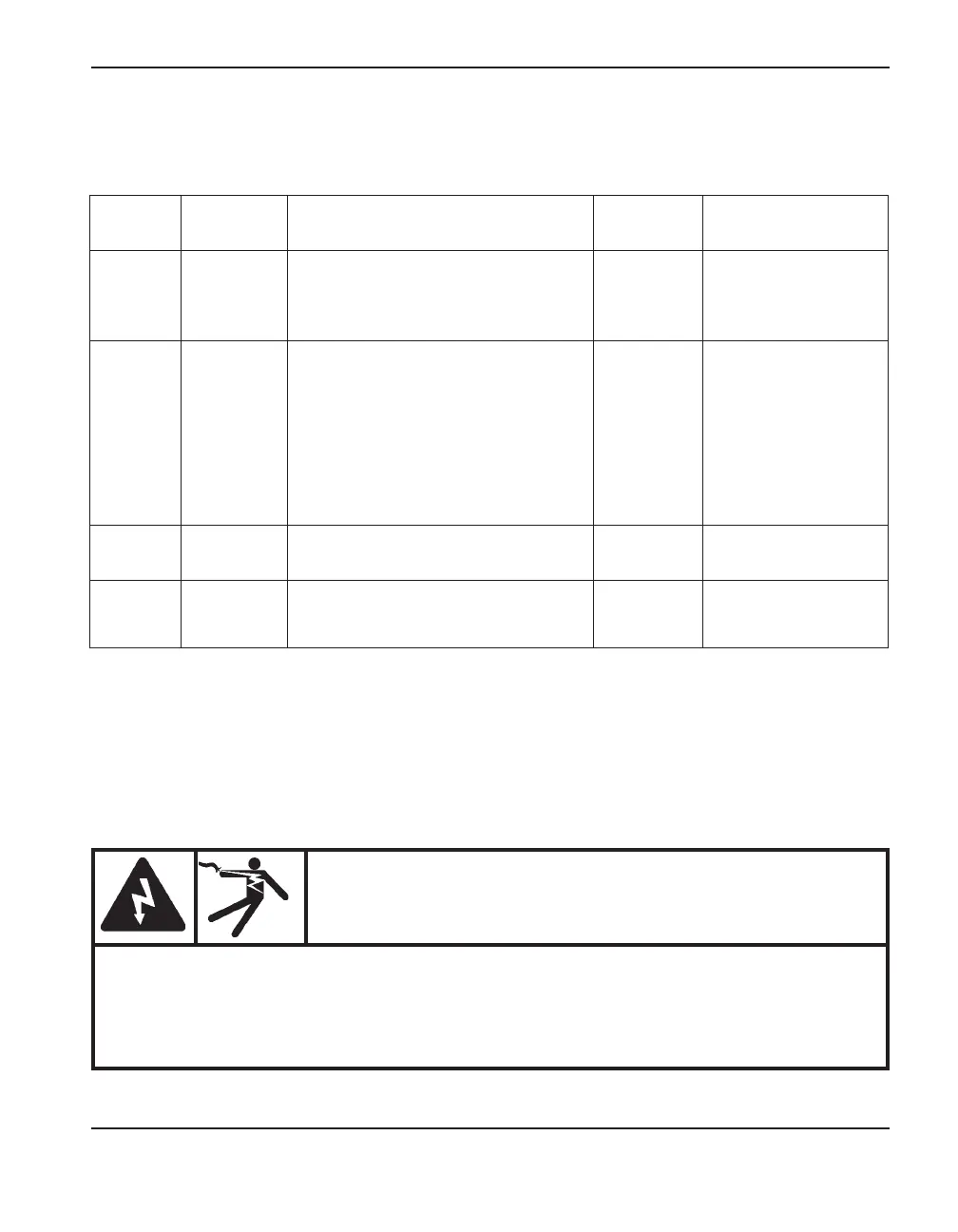

Signal Type Notes

Connector

sockets

Cable wires

Start

(start

plasma)

Input

Normally open.

18 VDC open circuit voltage at

START terminals. Requires dry

contact closure to activate.

3, 4 Green, black

Transfer

(start

machine

motion)

Output

Normally open. Dry contact closure

when the arc transfers.

120 VAC/1 A maximum at the

machine interface relay or switching

device (supplied by the customer).

12, 14 Red, black

Ground Ground 13

Voltage

divider

Output

Divided arc signal of 20:1, 21.1:1,

30:1, 40:1, 50:1 (provides a

maximum of 18 V).

5, 6 Black, white

Loading...

Loading...