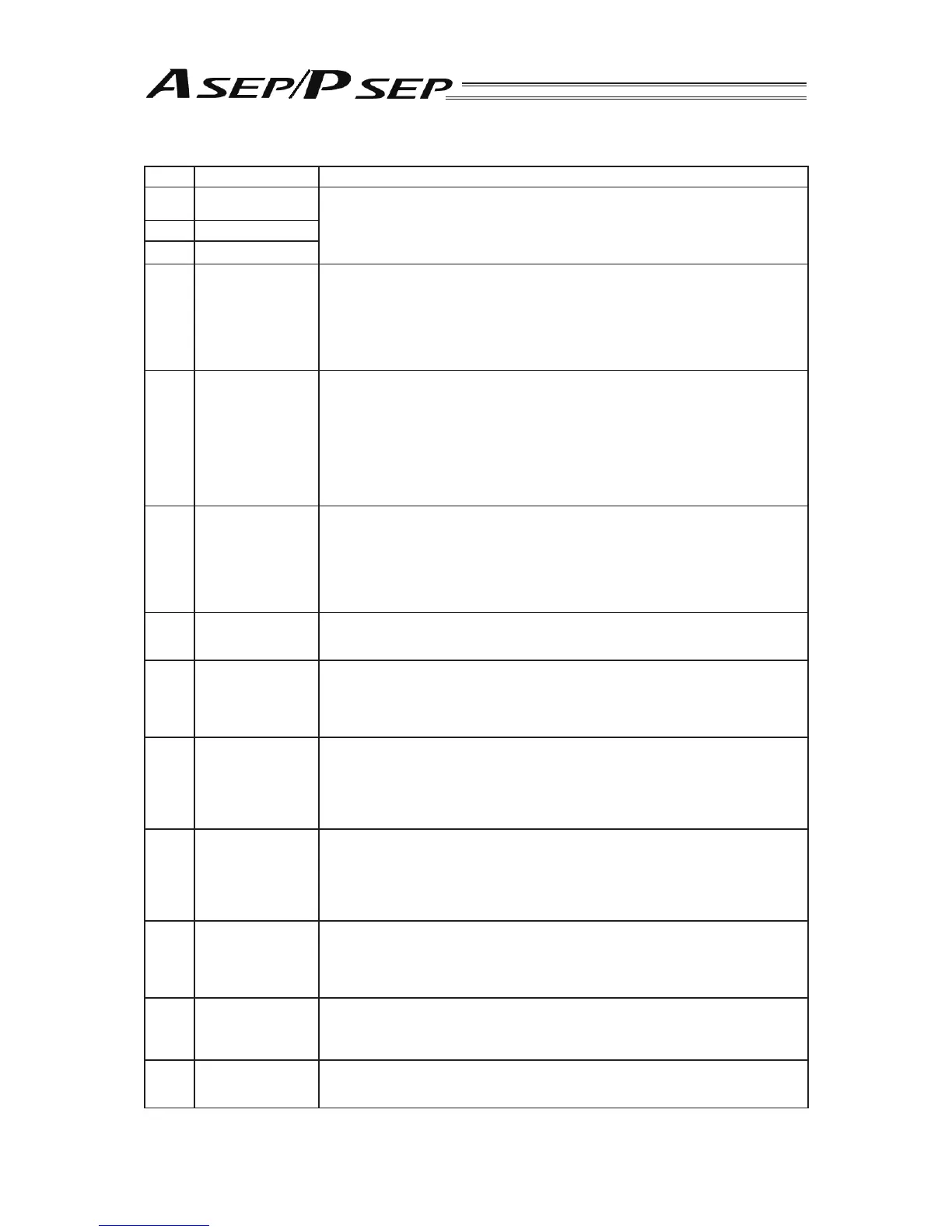

47

Code Alarm Name Cause/Treatment

0E8

A or B-phase Wire

Breakage

The encoder signal is not detected normally.

Cause : A looseness or wire breakage in the connector section of the actuator connecting cable is

considered.

Treatment : Check for the connection condition of the actuator connecting cable and perform the continuity test.

If normal, contact our company.

0E9 A -phase Wire Breakage

0EA B-phase Wire Breakage

0ED

Absolute Encoder Error

Detection 1

Cause : (1) When the absolute unit reset is completed and the power is re-input, the current position might

be changed due to an external force.

(2) When the absolute unit is reset, the current position might be changed due to an external force.

Treatment : (1) Turn OFF the power and arrange so that a vibration is not added to the actuator and turn ON the

power again.

(2) Arrange so that a vibration is not added to the actuator and perform the home return operation

again.

0EE

Absolute Encoder Error

Detection 2

Cause : (1) It might be caused in the simplifi ed absolute type when the power is turned ON for the fi rst time

after the battery is connected.

(2) The battery voltage is too much decreased to keep the encoder counter operation.

(3) The encoder cable is disconnected during the power failure, or a wire breakage occurs in the

encoder cable.

(4) The parameter is changed.

Treatment : In the case of (1), (2) or (4), perform the Absolute Reset operation according to the procedure.

(2) Supply the power for 72 hours or more to charge the battery suffi ciently and then perform the

Absolute Reset operation.

0EF

Absolute Encoder Error

Detection 3

Cause : The current value is increased to the velocity value more than specifi ed in the motor speed setting

due to an external force, etc., while the power is turned OFF.

Treatment : Take the measure so that the actuator is not moved at the speed more than the set value while the

power is turned OFF.

In the case that there is still enough time before the battery shutoff, increase the set value for the

parameter No.19.

After any error occurs, perform the Absolute Reset operation.

0F0 Driver Logic Error

Cause : An overload, parameter (Motor Type) setting not correct, or noise controller breakdown, etc., is

supposed.

Treatment : Contact our company.

0F4

PC Board Mismatching

Error

In this controller, because of the motor capacity, the divided placement is performed on a single PC board. This

error might be caused when it is found in the check before the startup that the motor type does not appropriate

for the PC board.

Cause : A parameter setting error or PC board setup error is considered.

Treatment : When this error occurs, contact our company.

0F5

Non-Volatile Memory

Write Verifi cation Error

When the data is written on the non-volatile memory (EEPROM), the original data is compared to the written

data to confi rm whether if it is the same or not. This error is caused when the data is not the same.

Cause : (1) A breakdown of the non-volatile memory is considered.

(2) The reload times might exceed 100,000.

(The standard nominal reload times for non-volatile memory is 100,000).

Treatment : When the error is caused even when the power is re-input, contact our company.

0F6

Non-Volatile Memory

Write Time Out

This shows that no response is received within the specifi ed time period when the data is written on the non-

volatile memory.

Cause : (1) A breakdown of the non-volatile memory is considered.

(2) The reload times exceed 100,000.

(The standard nominal reload times for non-volatile memory is 100,000).

Treatment : When the error is caused even when the power is re-input, contact our company.

0F8

Non-Volatile Memory

Data Breakdown

A data error is detected in the non-volatile memory check in the startup operation.

Cause : (1) A breakdown of the non-volatile memory

(2) The reload times exceed 100,000.

(The standard nominal reload times for non-volatile memory is 100,000).

Treatment : When the error is caused even when the power is re-input, contact our company.

0FA CPU Error

The CPU operation is not normal.

Cause : (1) A breakdown of the CPU itself is supposed.

(2) An operation error due to a noise is supposed.

Treatment : When the error is caused even when the power is re-input, contact our company.

0FC Logic Error

Inside the controller does not function normally.

Cause : A part breakdown inside the controller or operation error due to a noise is considered.

Treatment : When the error is caused even when the power is re-input, contact our company.

Loading...

Loading...