MAN-045 ING

15

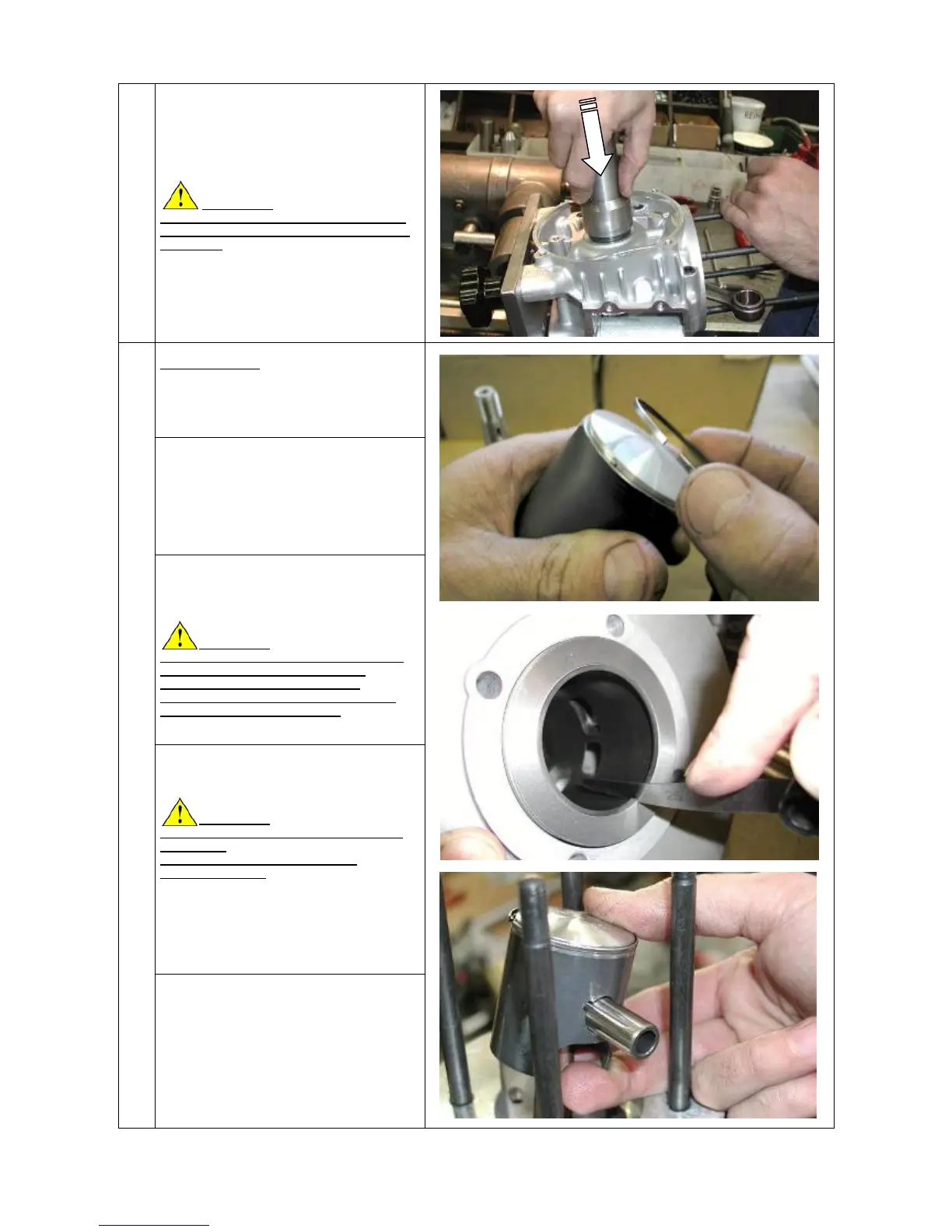

INSERT OIL SEALS .

USE TOOL AS PER DRAWING S725/3

(see Fig.10).

(MARK ON THE OIL SEAL MUST BE TOWARDS

THE EXTERNAL).

ATTENTION:

THE OIL SEAL MUST BE REPLACED AFTER

MAX. WORKING 6 HRS AND ALWAYS WHEN

REMOVED.

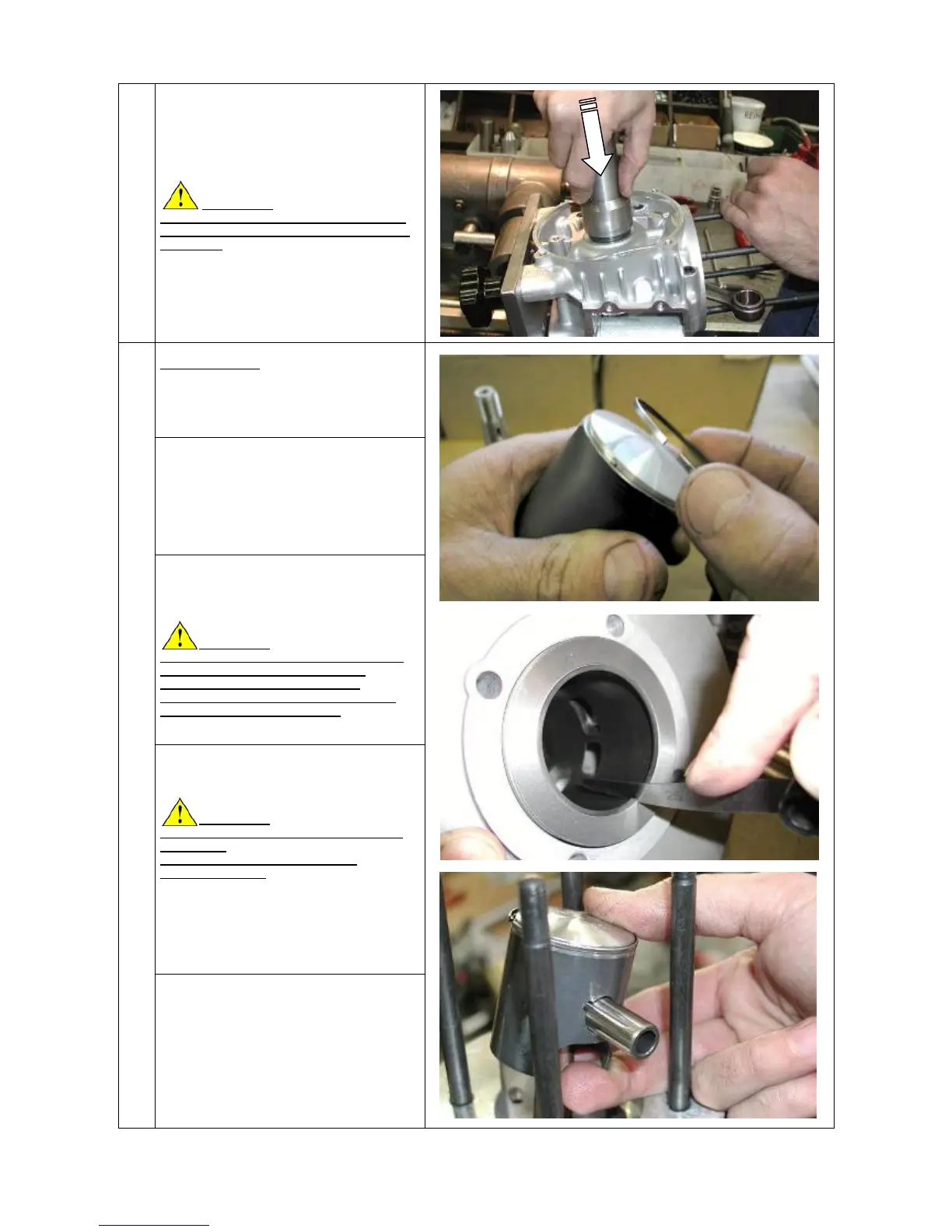

INSTALL PISTON

:

a) CHECK STATUS OF THE ROLLER CAGE.

IT MUST BE REPLACED AFTER MAX. 4

WORKING HRS.

b) CHECK STATUS OF PISTON PIN

REPLACE THE PISTON PIN WHEN

REPLACING PISTON.

(SEE ATTACHMENT ON MATCHING

SELECTIONS BETWEEN CONROD /

PISTON PIN / ROLLER CAGE).

c) INSTALL RING ON THE PISTON

(see Fig.11).

ATTENTION:

CHECK PLAY ON PISTON RING END GAPS

TO BE BETWEEN 0.10 AND 0.15mm.

PLAY MUST BE CHECKED USING A

THICKNESS GAUGE AND INSERTING THE

PISTON RING IN THE CYLINDER (see Fig.12)

d) INSTALL PISTON

ATTENTION:

PLAY BETWEEN PISTON AND LINER MUST

BE 0.08mm.

IF PLAY IS HIGHER THAN 0.10mm,

REPLACE PISTON.

FOLLOW ATTACHED INSTRUCTIONS FOR

CORRECT MATCHING.

PISTONS ARE MEASURED AT 15mm FROM

THE BOTTOM (see attachment).

ALWAYS CHANGE PISTON COMPLETE WITH

RINGS.

3.

e) IINSERT PISTON PIN AND ROLLER CAGE

IN THE PISTON (see Fig.13).

MAKE SURE THAT ARROW ON TOP OF

PISTON IS TOWARDS EXHAUST.

AS A GENERAL RULE, PISTON PIN MUST

BE FORCED IN HOLE. IF PISTON PIN IS

LOOSE IN SEAT, REPLACE IT WITH A

HIGHER DIAMETER PIN.

Fi

Loading...

Loading...