24

Installation and Servicing

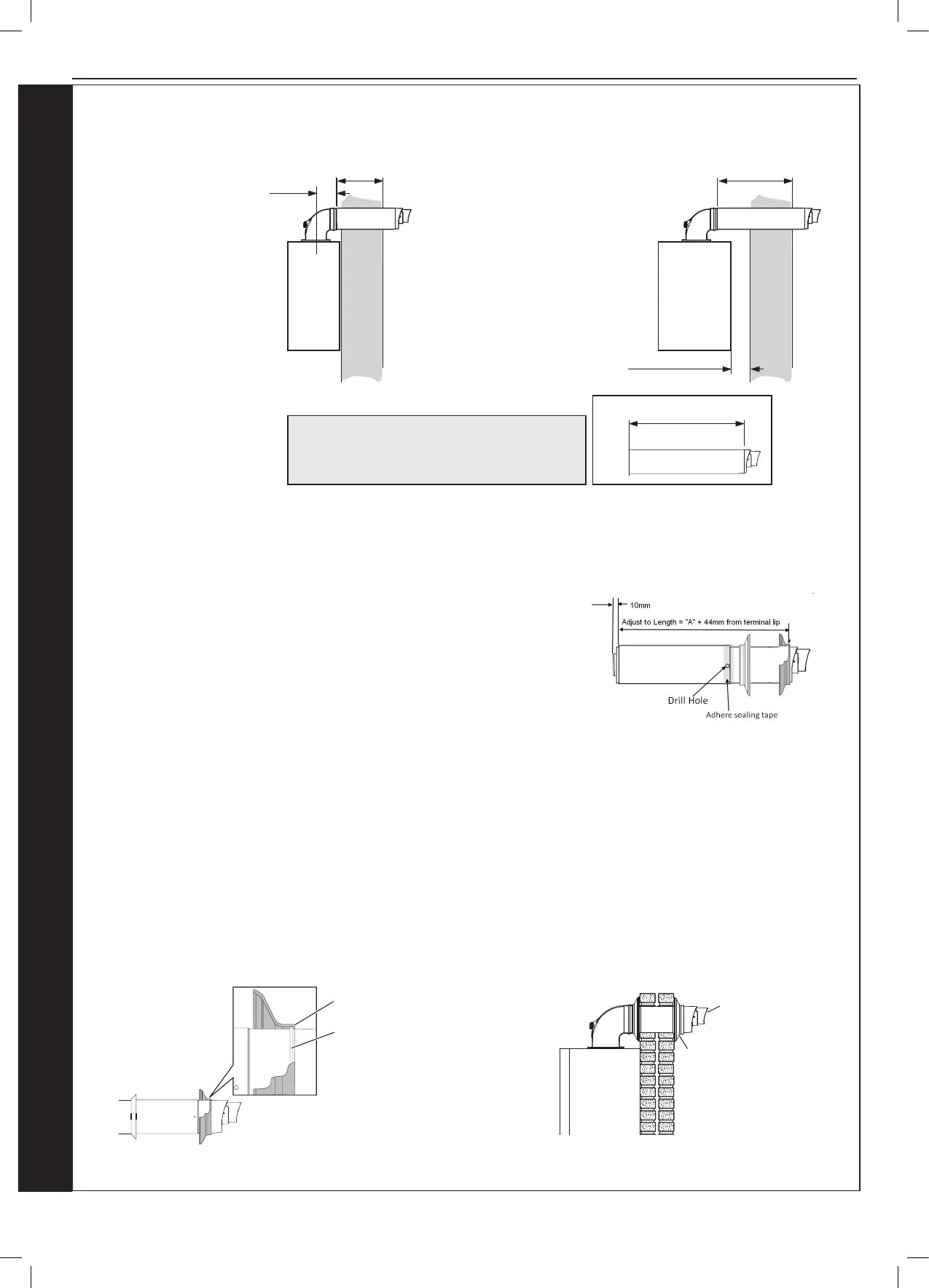

FLUE OUTLET

SECTION 2 - INSTALLATION

100mm

to outside face of wall plus

44mm = ue length

Centre of turret to edge of turret = 100mm

Turret has a ue insertion of 30mm

The compressed outer wall seal has protruding wall to seal mounting lip - 14mm

From centreline of turret to wall. Rear mount 155mm, side (including clearance) 200mm

NOTES

REAR

Fit

to wall

A

WALL

Flue length measured from outer terminal lip

to end of outer ue

A + 44mm

to outside face of wall plus

44mm = ue length

SIDE

Fit

to wall

A

WALL

Minimum clearance 5mm

....... DETERMINING THE FLUE LENGTH AND FLUE PACKS REQUIRED, CONT’D

FIGURE 1

Note. Maximum permissible

ue length is measured from

centre line of appliance ue

outlet to outside wall face.

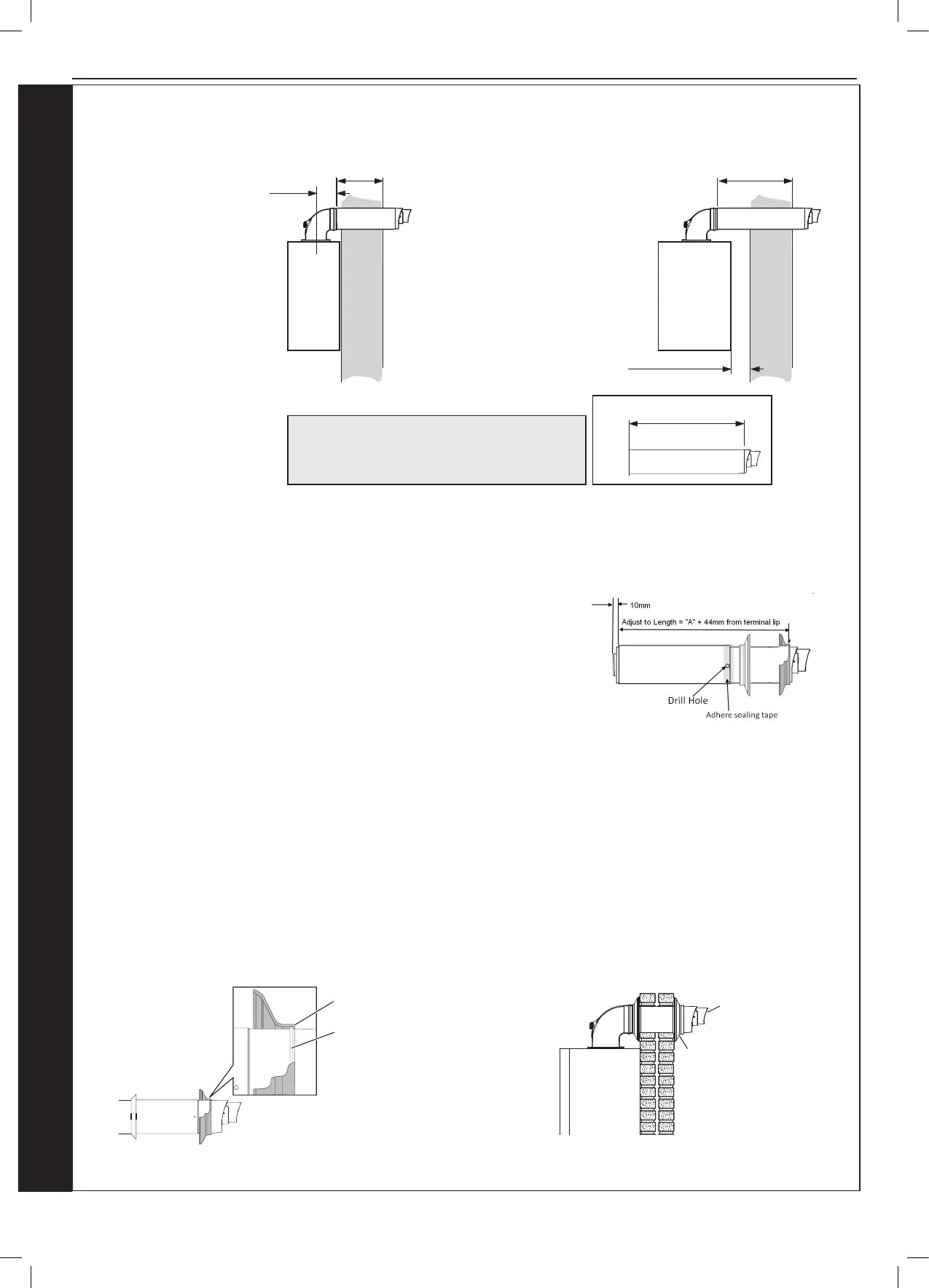

2.14 CUTTING & SETTING THE FLUE LENGTH

SETTING TELESCOPIC FLUE B PACKS

1. Measure the required ue length (A+44mm).

2. Measure from the outer terminal lip to end of outer ue. Pull apart ue until

desired length is achieved. ENSURE THE STOP MARK IS NOT VISIBLE, IF

IT IS, THE FLUE IS TOO SHORT AND SHOULD NOT BE USED.

3. Check that both ue seams are at the top and the outlet terminal is uppermost.

4. Drill a 3.5mm hole through one of the 2 outer side holes in the outer ue

section into the inserted outer ue (as shown). Take care not to pierce the

inner plastic ue. Fit screw provided.

5. Seal the joint on the outer air duct with the tape provided.

6. Fit internal and external wall seals (see installing ue).

2.15 INSTALLING THE FLUE (INTERNAL BOILER)

FITTING FLUE THROUGH THE WALL

1. Fit external black wall seal ensuring the inside of the outer lip is in contact with the terminal lip you have been measuring from

(see g 1).

2. Place the ue through the wall.

3. Fit the internal wall seal.

4. Ensure the seam and the outlet terminal are at the top and tted as shown.

Ensure lip of wall seal is positioned

over step on plastic nose of flue terminal

(note, seal is cut away for clarity)

Terminal Lip

Wall Seal Lip

Rubber

Terminal

Wall Seal

Terminal

MUST be

fitted as

shown

Fig 1

continued . . . . . .

Loading...

Loading...