Surface treatment

Corrosion

Corrosion is a complicated chemical process. In extremely simple terms, it could be described as a reaction between a

substance and its surroundings. In the case of the sheet metal used in cars, it is iron which reacts with water and oxygen to

form ferric hydroxide or what we usually call rust.

One of the first steps in manufacturing iron is to remove the oxygen from the iron ore. This is necessary to make the iron

sufficiently strong for further processing. Pure iron is, however, chemically unstable. The iron always strives to take back

the oxygen and form ferric hydroxide (rust), which is stable.

If iron is to be able to form ferric hydroxide to any greater extent, then water is needed as well as oxygen. The water acts as

an electrolyte and starts the electromagnetic process that helps the unstable iron to absorb oxygen from the atmosphere.

Ferric hydroxide has a larger volume than iron, which makes the sheet metal crack when it corrodes. More oxygen and

water forces its way in and the corrosion worsens.

The corrosive process will be accelerated if the electrolyte (water) contains salt. Other factors that help cause corrosion are

heat and impurities in the surface of the iron.

The sheet metal is protected against corrosion by eliminating the factors that lead to its onset. The most common method is

to prevent water and oxygen from coming into contact with the sheet metal. On the Samand this is accomplished by

applying several coats of paint. In addition, large parts of the body are coated with zinc, which makes the metal less prone

to corrosion.

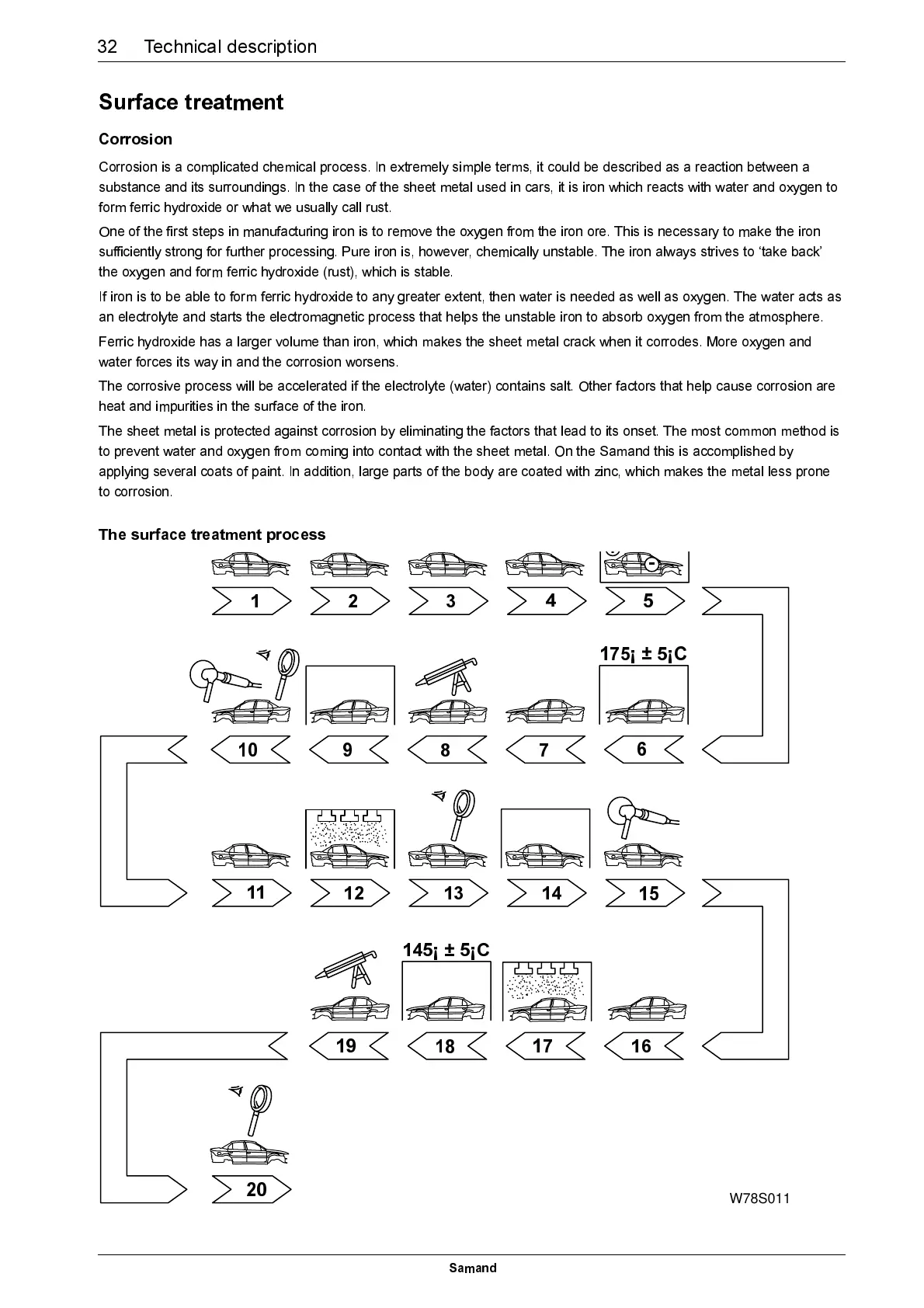

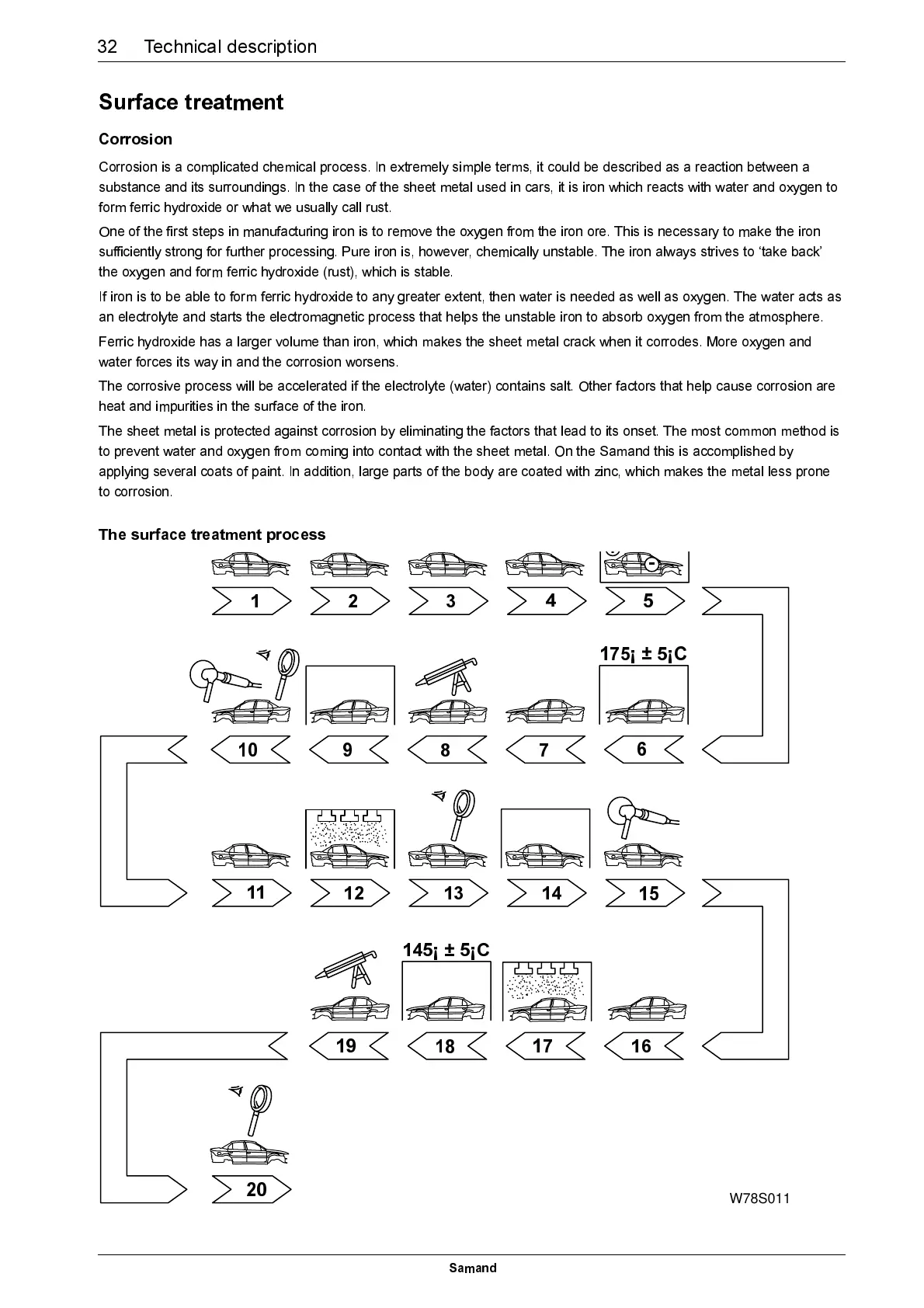

The surface treatment process

Samand

32

Technical description

Loading...

Loading...