4

Wet the caps (tap water before fitting them to aid

impregnation with the zinc solution.

Screw the anode to the pad holder.

Place the cap on the anode.

Place the cap and anode assembly in the plastic

container.

Pour zinc solution into the plastic container.

Set the generator potentiometer to position 6.

When zinc is being deposited, the ammeter will

then read 20A. This setting gives an even deposit

with a good surface condition.

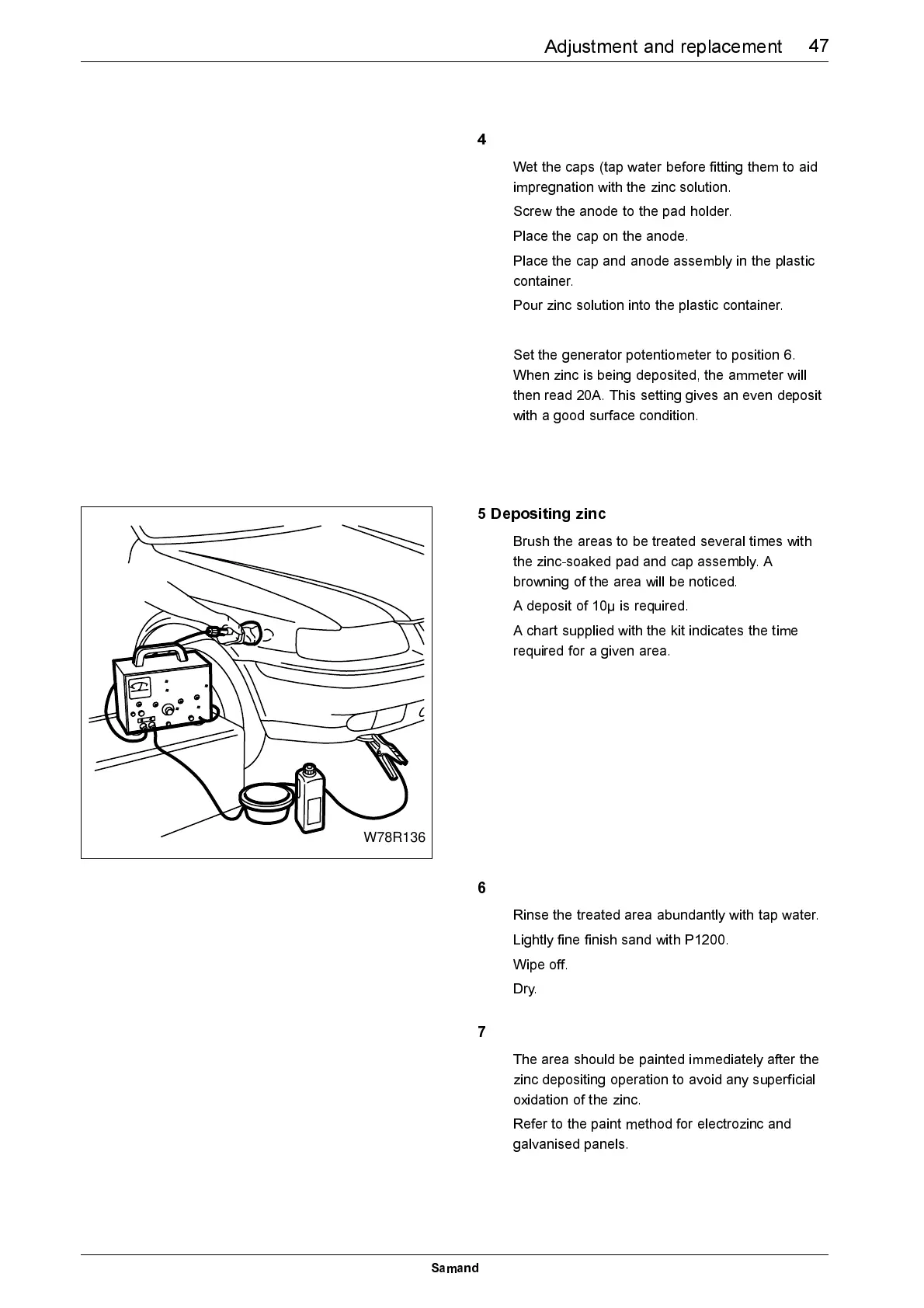

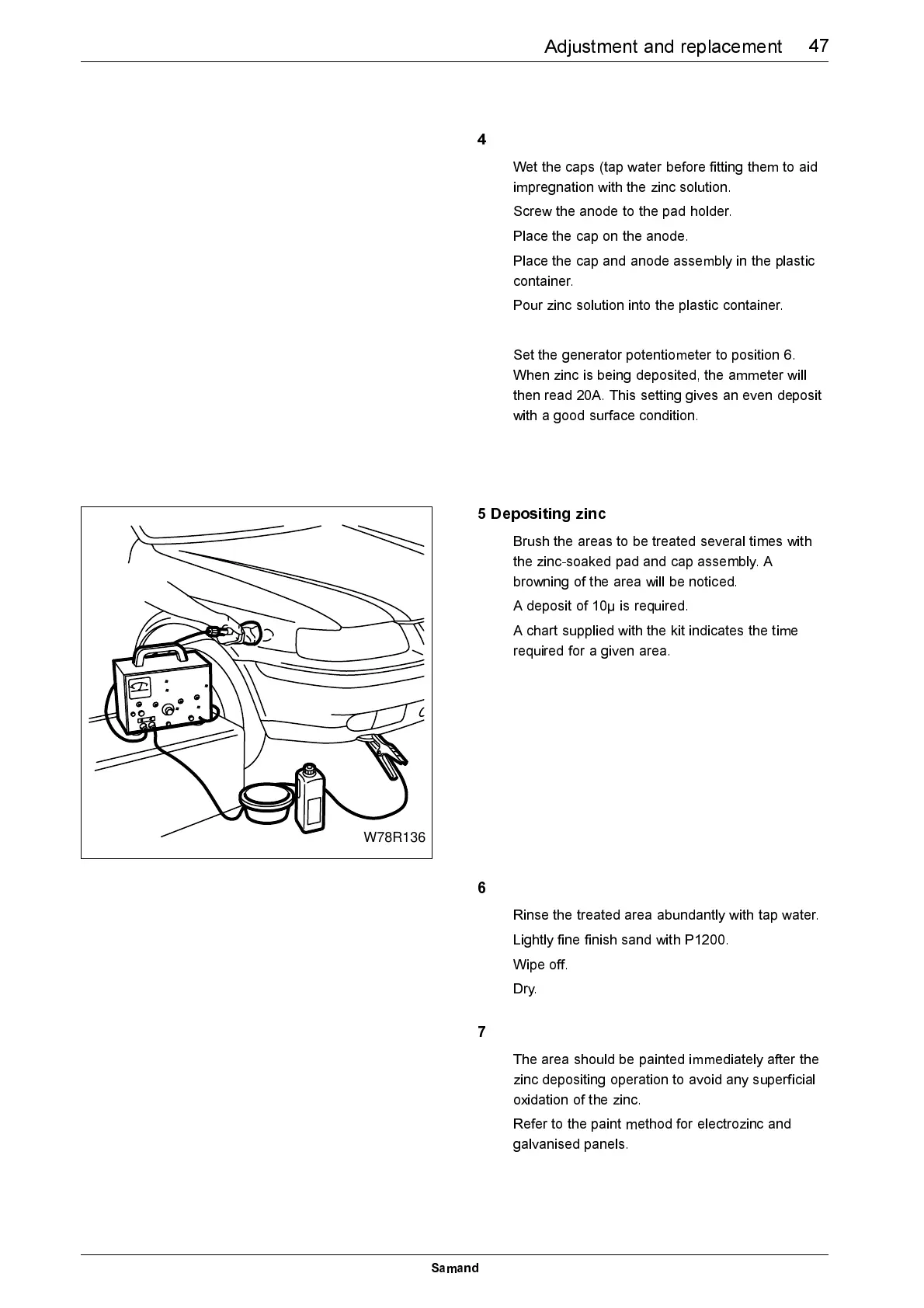

5 Depositing zinc

Brush the areas to be treated several times with

the zinc-soaked pad and cap assembly. A

browning of the area will be noticed.

A deposit of 10µ is required.

A chart supplied with the kit indicates the time

required for a given area.

6

Rinse the treated area abundantly with tap water.

Lightly fine finish sand with P1200.

Wipe off.

Dry.

7

The area should be painted immediately after the

zinc depositing operation to avoid any superficial

oxidation of the zinc.

Refer to the paint method for electrozinc and

galvanised panels.

Loading...

Loading...