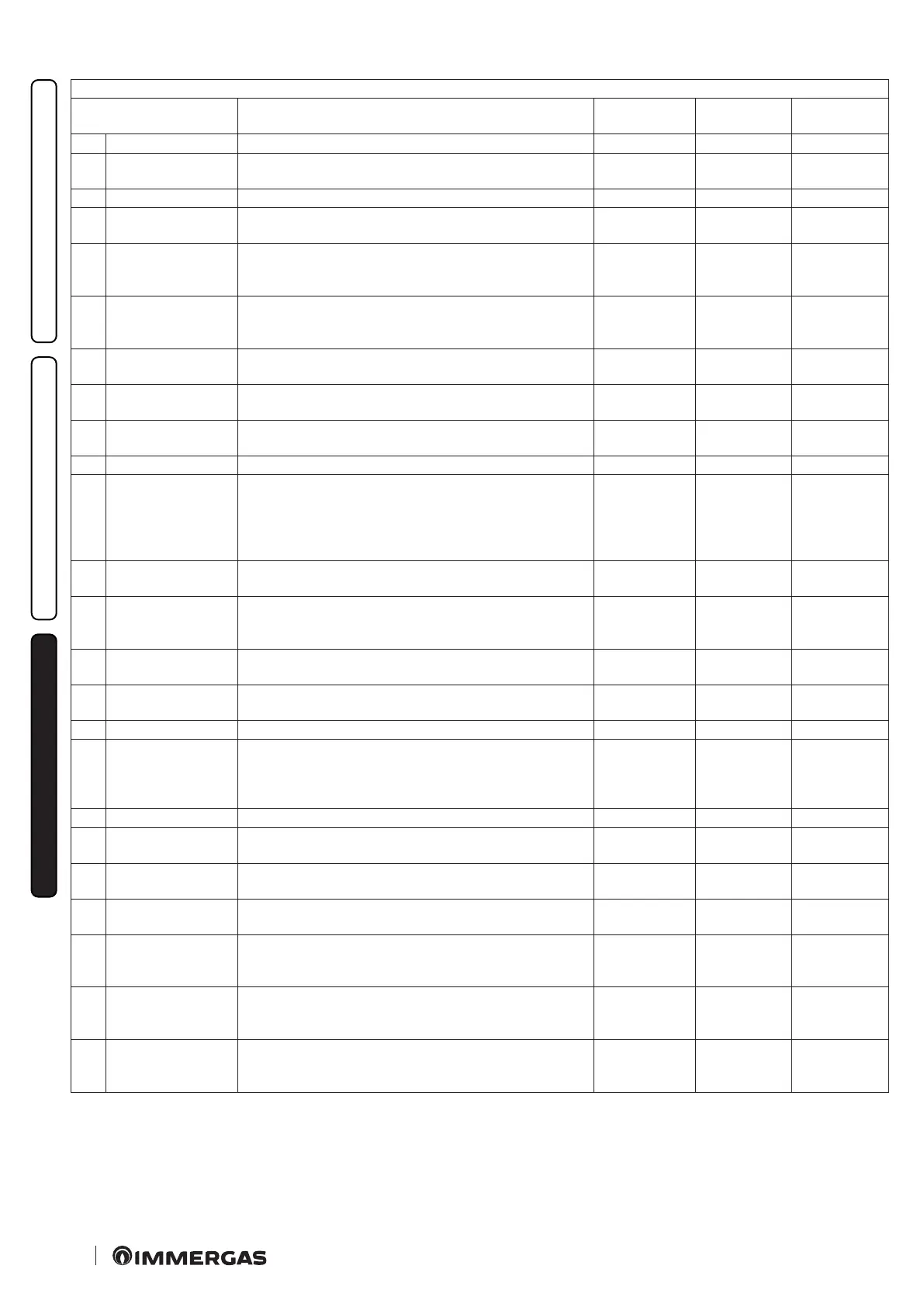

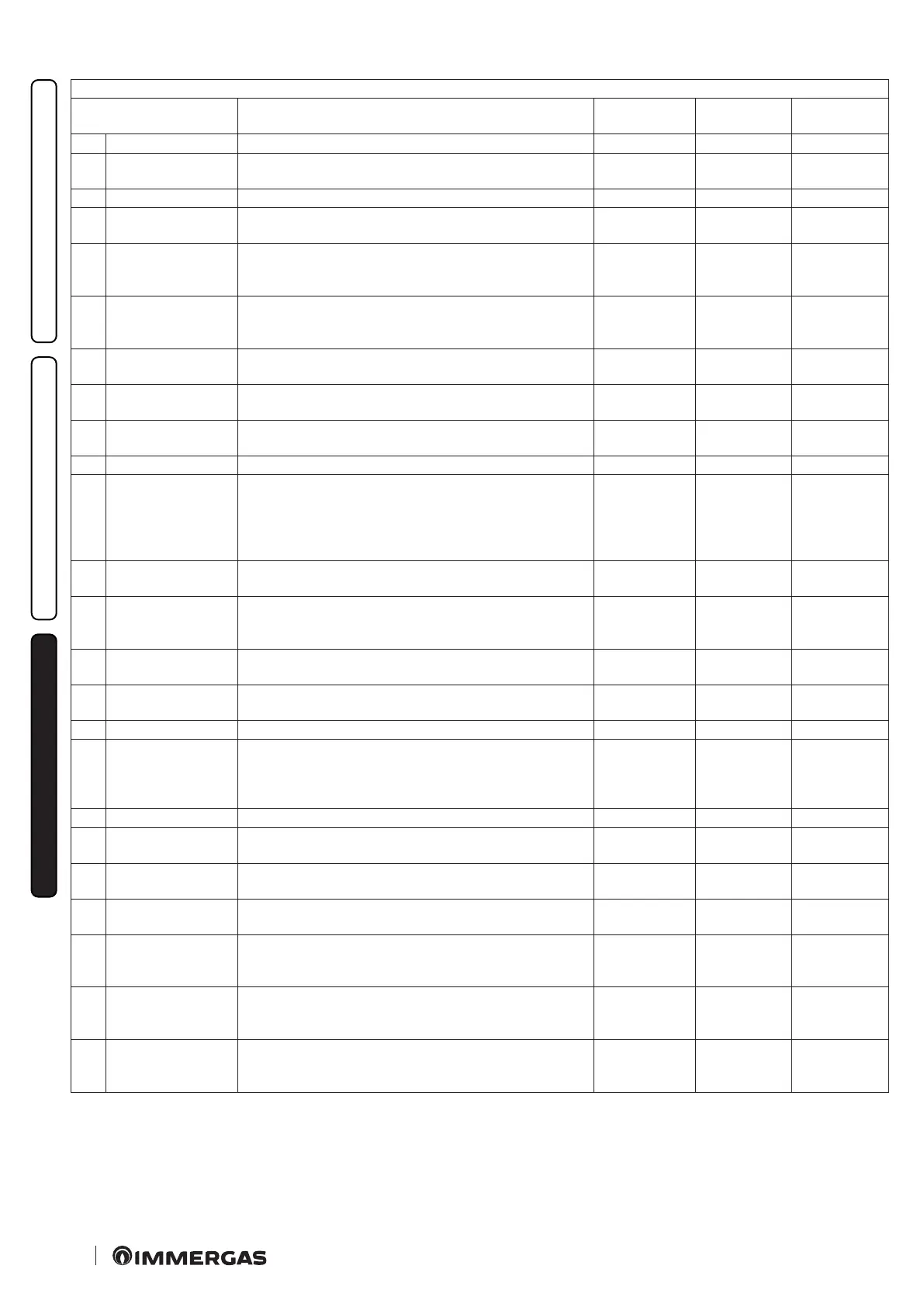

44

INSTALLERUSER

MAINTENANCE TECHNICIAN

Programming menu

Menu item Description

Adjustment

range

Default value

Customised

Value

P01 CH Set is denes the boiler's ow temperature during heating 20 ÷ P02 °C 85

P02 Max CH Set

is denes the maximum settable ow temperature during

heating

20 ÷ 95 °C 85

P03 Heating Hysteresis is denes the power-o hysteresis during the heating phase 2 ÷ 10 °C 5

P04 Anti-cycle CH

is is used to set a waiting time to avoid the boiler from

switching on multiple times and frequently during CH mode

0 ÷ 15 minutes 3 minutes

P05 CH min time

is is the amount of time that the boiler needs to stabilise,

when the burner runs at minimum power for the set amount

of time

3 ÷ 10 minutes 3 minutes

P06 CH ramp

e amount of time that the boiler takes to reach the required

temperature, number of degrees per minute (0 means no

ramp)

0 ÷ 60 °C/

minute

4 °C/minute

P07 CH post-circulation

e amount of CH post circulation once the CH phase is

fnished

1 ÷ 30 minutes 3 minutes

P08

Available max heat

out

is denes the maximum power percentage to be used

during the set CH phase

P09 ÷ 100% 100%

P09

Available max heat

out

is denes the minimum power percentage to be used

during the set CH phase

0 ÷ P08% 0%

P10 - Not used 14 l/minutes

P11

Electrodes anti-

humidity

is denes fan speed and operating mode, to avoid humidity

inside the condensing module, which could otherwise

cause the electrodes to malfunction (0 = disabled function,

recommended value = 40) (RPM speed is calculated by

multiplying the value displayed by 50)

P26 ÷120 0

P12

Boiler’s modulation

ratio

It denes the boiler’s modulation ratio

(Do not modify)

0 ÷ 100% 10%

P13 Boiler power

Used to calculate the boiler power in the event of simple

cascade.

0 ÷ 255 kW

80 kW = 75

100 kW = 90

120 kW = 115

P14 External probe curve

is is used to select the external probe operating curve

(optional) (0 = disabled probe)

0 ÷ 10 0

P15 External probe oset

is denes the CH oset in relation to the selected external

probe curve

20 ÷ 70 °C 30 °C

P16 DHW set is denes the DHW temperature 35 ÷ 65 °C 65 °C

P17

P17 External D.H.W /

3-waypump

- With single boiler and common ow probe, it lets you

choose between an external D.H.W pump and a 3-way one.

- With a simple cascade, it manages a D.H.W. pump

(downstream an hydraulic separator).

0 = 3 Ways

1 = D.H.W.

pump

P18 DHW hysteresis is denes the DHW power-on hysteresis during CH 2 ÷ 10 °C 5 °C

P19

DHW post-

circulation

is is the post circulation time during DHW once DHW

production is nished

0 ÷ 180 seconds 60 seconds

P20

Available max DHW

pow

is denes the maximum power percentage to be used

during the set DHW phase

P21 ÷ 100 % 50 %

P21

Available max DHW

pow

is denes the minimum power percentage to be used

during the set DHW phase

0 ÷ P20 % 0 %

P22

DHW ow

temperature with

thermostat

In combination with a storage tank and a separate thermostat,

this denes the ow temperature during DHW operation

35 ÷ 90 °C 80 °C

P23 DHW modulation

Summed with the “Set San” (P16) parameter, this denes the

ow temperature set that the boiler has to modulate the power

on during DHW

5 ÷ 30 °C 15 °C

P24 DHW o increment

is denes the time that the boiler allows the burner to

switch o during DHW, by an increment of 5 °C on top of the

ow temperature

0 ÷ 255 seconds 60 seconds

Loading...

Loading...