Chapter 3 Environment description and installation

3-7

3.3 Electrical Installation

3.3.1 Notice for wiring

A. Screwdriver torque:

Connect cables with a screwdriver or other suitable tools and follow the torque listed below.

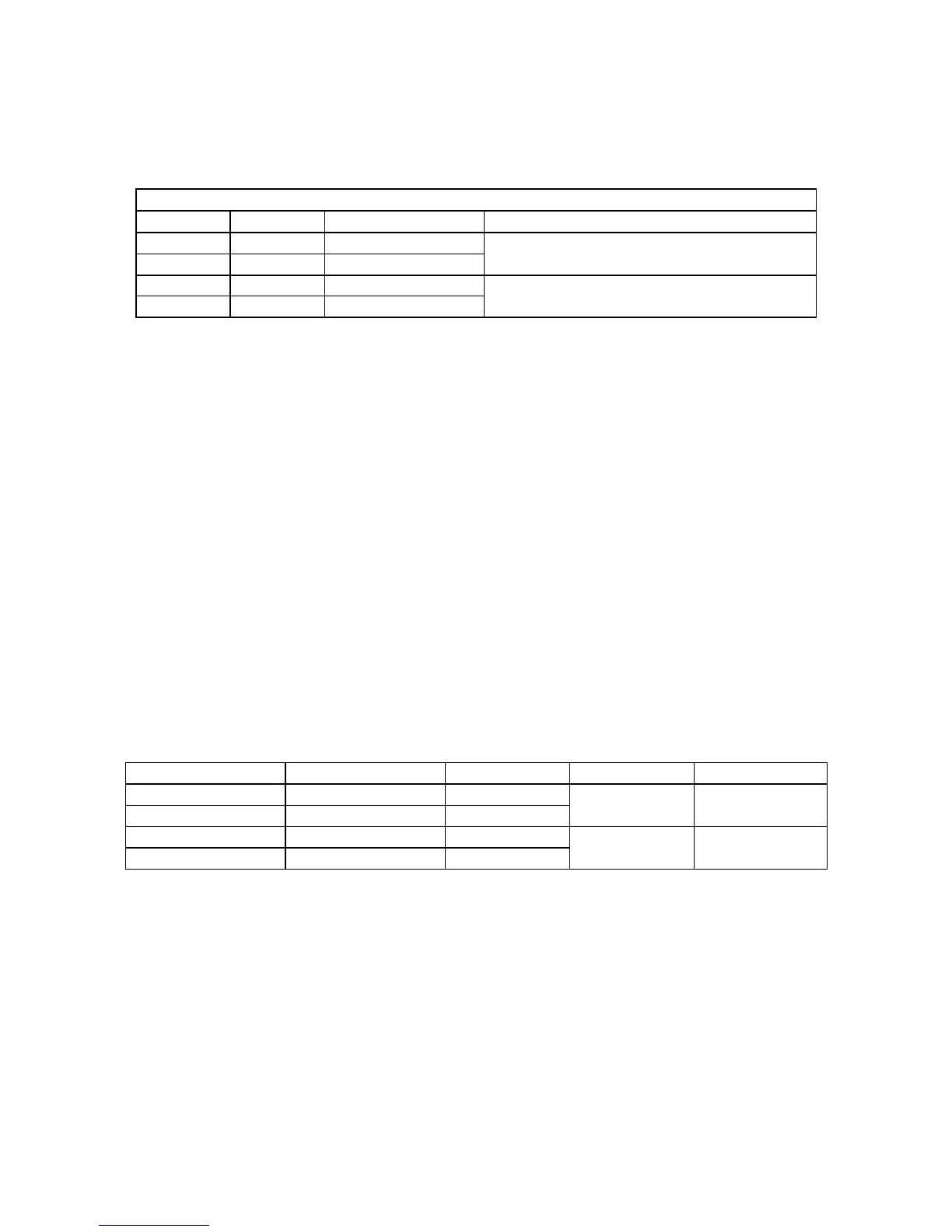

Tightening torque

Horsepower KW Power source Nominal torque for TM1 terminal

0.25/0.5/1 0.2/0.4/0.75 100-120V

0.25/0.5/1 0.2/0.4/0.75 200-240V

0.74 / 1.00

(lbs-ft / Nm)

2/3 1.5/2.2 200-240V

1/2/3 0.75/1.5/2.2 380-480V

1.286 / 1.74

(lbs-ft / Nm)

B. Power cables:

Power cables are wires connected to L1(L), L2, L3 (N), T1, T2, T3, P and N. Choose cable in

accordance with the following criteria:

(1) Use cable with copper cores only. Select cable with insulation diameter based on working

conditions at 105P

o

P

C.

(2) For nominal voltage ratings, use cable rated at minimum 300V for 240Vac iDrives and

600V rated cable for 480Vac iDrives.

C. Control cables:

Control cables are connected to TM2 control terminals. Choose cable in accordance with the

following criteria:

(1) Use cable with copper cores only. Select cable with insulation diameter based on working

conditions at 105P

o

P

C.

(2) For nominal voltage ratings, use cable rated at minimum 300V for 240Vac iDrives and

600V rated cable for 480Vac iDrives.

(3) To avoid noise interference, do not run control cables in the same conduit or trunking as

power cables.

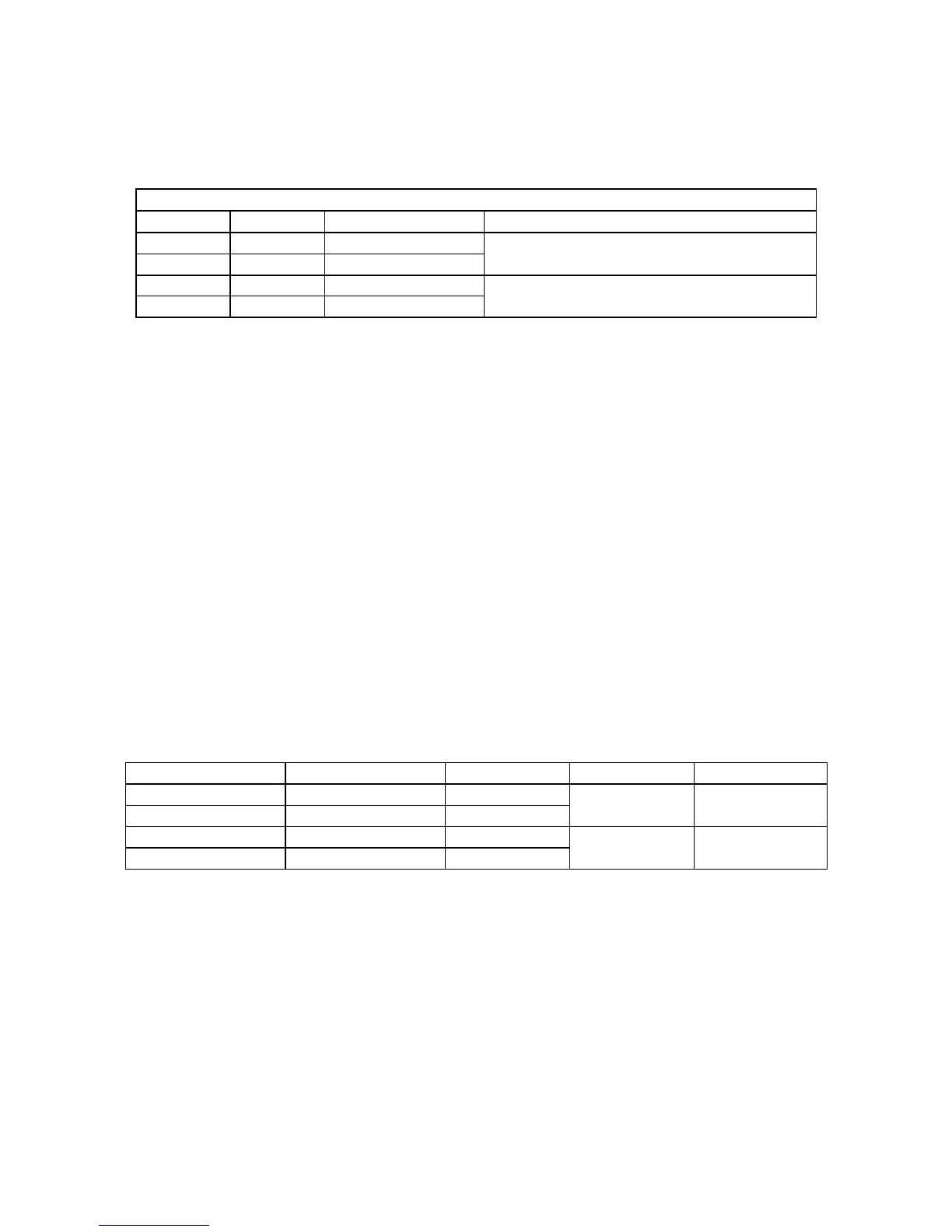

D. Nominal electrical specifications of terminal block TM1:

KW Horsepower Power source Volts Amps

0.2 / 0.4 / 0.75 0.25 / 0.5 / 1 100-120V

0.2 / 0.4 / 0.75 0.25 / 0.5 / 1 200-240V

600 15

1.5 / 2.2 2 / 3 200-240V

0.75 / 1.5 / 2.2 1 / 2 / 3 380-480V

600 40

Loading...

Loading...