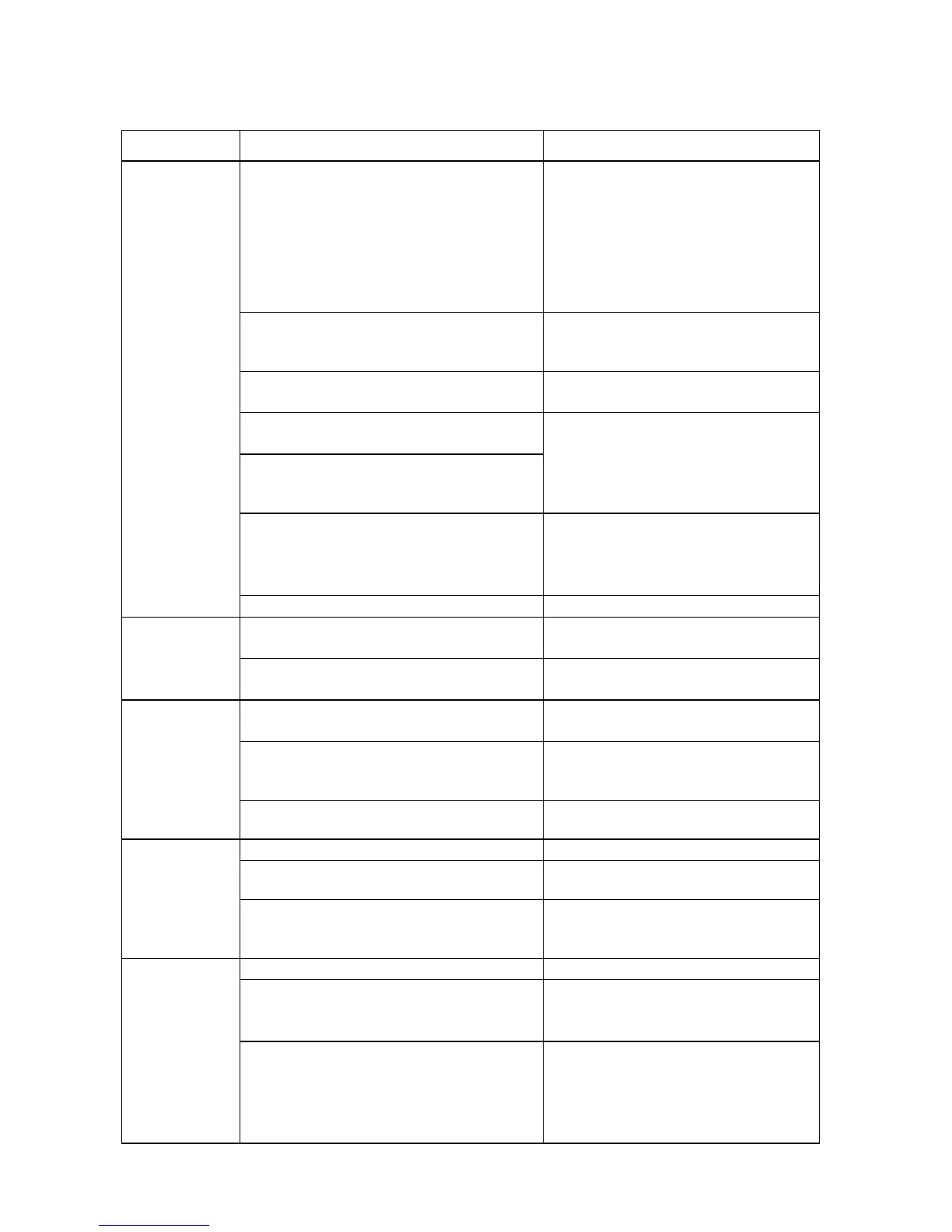

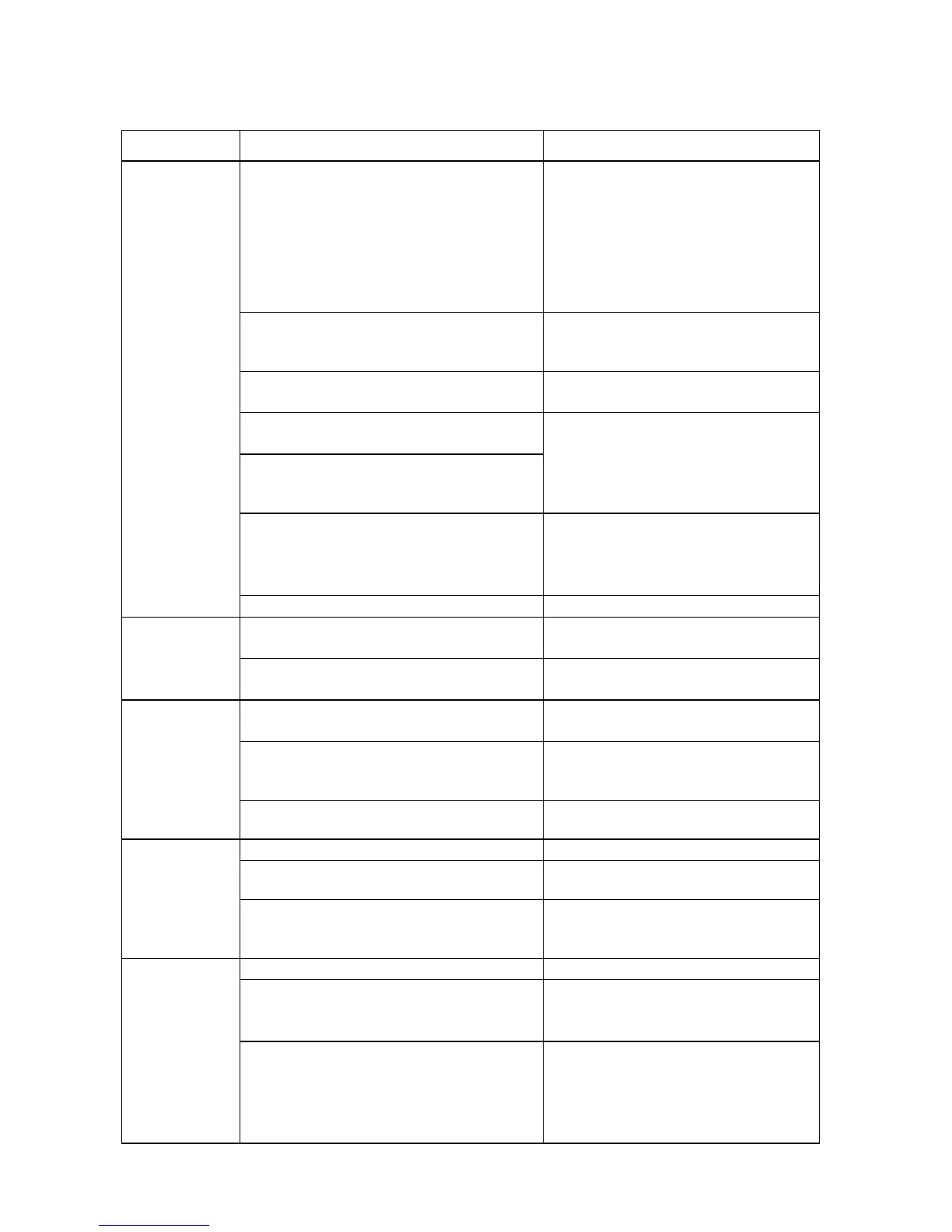

Chapter 5 Trouble shooting and maintenance

5-6

5.2 General functional troubleshooting

Status Checking point Remedy

Is power applied to L1, L2, and L3(N)

terminals (is the charging indicator lit)?

Is the power applied?

Turn the power OFF and then ON

again.

Make sure the power voltage is

correct.

Make sure terminals are fully

tightened.

Is there voltage output at T1, T2, and T3

terminals?

Turn the power OFF and then ON

again.

Is the motor mechanically overloaded?

Reduce the load to allow the motor

to rotate.

Are there any abnormalities in the

inverter?

Is forward or reverse run command

issued?

See error descriptions to check wiring

and correct if necessary.

Is there an analog input signal?

‧Is analog frequency input signal

wiring correct?

Is voltage of frequency input

correct?

Motor can not

run

Is operation mode setting correct?

‧Check parameter setting

Is output wiring on terminals T1, T2, and

T3 correct?

Wiring must match U, V, and W

terminals of the motor.

Motor runs in

wrong direction

Is wiring for forward and reverse signals

correct?

Check wiring is correct if necessary.

Are wiring for output terminals T1, T2,

and T3 correct?

Check wiring is correct if necessary.

Is the setting of frequency command

source correct?

Check the operation mode setting at

the keypad.

The motor

speed can not

vary

Is the mechanical load too heavy?

Reduce load.

Is the setting of operation mode correct? Confirm the motor’s specifications.

Is the load too heavy?

Confirm the gear ratio.

Motor running

speed too high

or too low

Are specifications of the motor (poles,

voltage…) correct?

Confirm the highest output

frequency.

Is the gear ratio correct? Reduce the load.

Is the setting of the highest output

frequency correct?

Minimize the variation of the load.

Increase capacities of the inverter

and the motor.

Motor speed

varies

unusually

Is the load too heavy?

Add an AC reactor at the power

input side if using single-phase

power.

Check wiring if using three-phase

power.

Loading...

Loading...