99903514:TELESCOPIC CRANE: 3-3 SECTION 3: REPAIR

3-4: CLEANLINESS

Keep dirt out of working parts to preserve the life

of the crane. Enclosed compartments, seals,

and filters have been provided to keep the air

supply, fuel, and lubricants clean. Maintain

these enclosures.

When any hydraulic oil, fuel, or lubricating oil

lines are disconnected, clean the adjacent

areas as well as the connection point. Once

disconnected, cap, plug, or tape each line to

prevent foreign material entry.

Clean and inspect all parts, and cover them

once clean. Be sure all passages and holes are

open. Install clean parts and leave new parts

packaged until assembly.

3-5: HYDRAULIC SYSTEM

The hydraulic system must be clean. Contami-

nants in the hydraulic system affect operation

and can cause component damage. When

working on the hydraulic system:

NEVER

- Allow foreign material including dirt, metal

particles, or water to enter the hydraulic

system. Cap all connections. If you find

evidence of foreign particles, flush the

system and replace filters.

ALWAYS

- Relieve hydraulic pressure.

- Inspect all seals during assembly and

disassembly. IMT recommends installing

new seals after hydraulic system repairs.

- Position hoses so they don’t rub on the

crane or other hoses. Maintain natural hose

curvature.

- Clean hydraulic components prior to assem-

bly, using an appropriate solvent and follow-

ing manufacturer precautions. Disassemble

and assemble components on a clean

surface.

- Cycle all controls after repair to eliminate

trapped air and alleviate erratic movement.

- Check for hydraulic leaks after repair. A

high-pressure leak is hazardous and must

be repaired prior to putting the unit back in

service.

WARNING

USE CLEANING SOLVENTS ONLY IN A

WELL-VENTILATED AREA WITH FIRE

EXTINGUISHERS READILY AVAILABLE.

3-6: FASTENERS & TORQUE VALUES

BOLTS: Use bolts of the correct length so the

bolt does not bottom out and enough threads

are engaged.

Torque values correspond to the bolts, studs,

and nuts used. Use hardened washers when

torquing nuts or bolts.

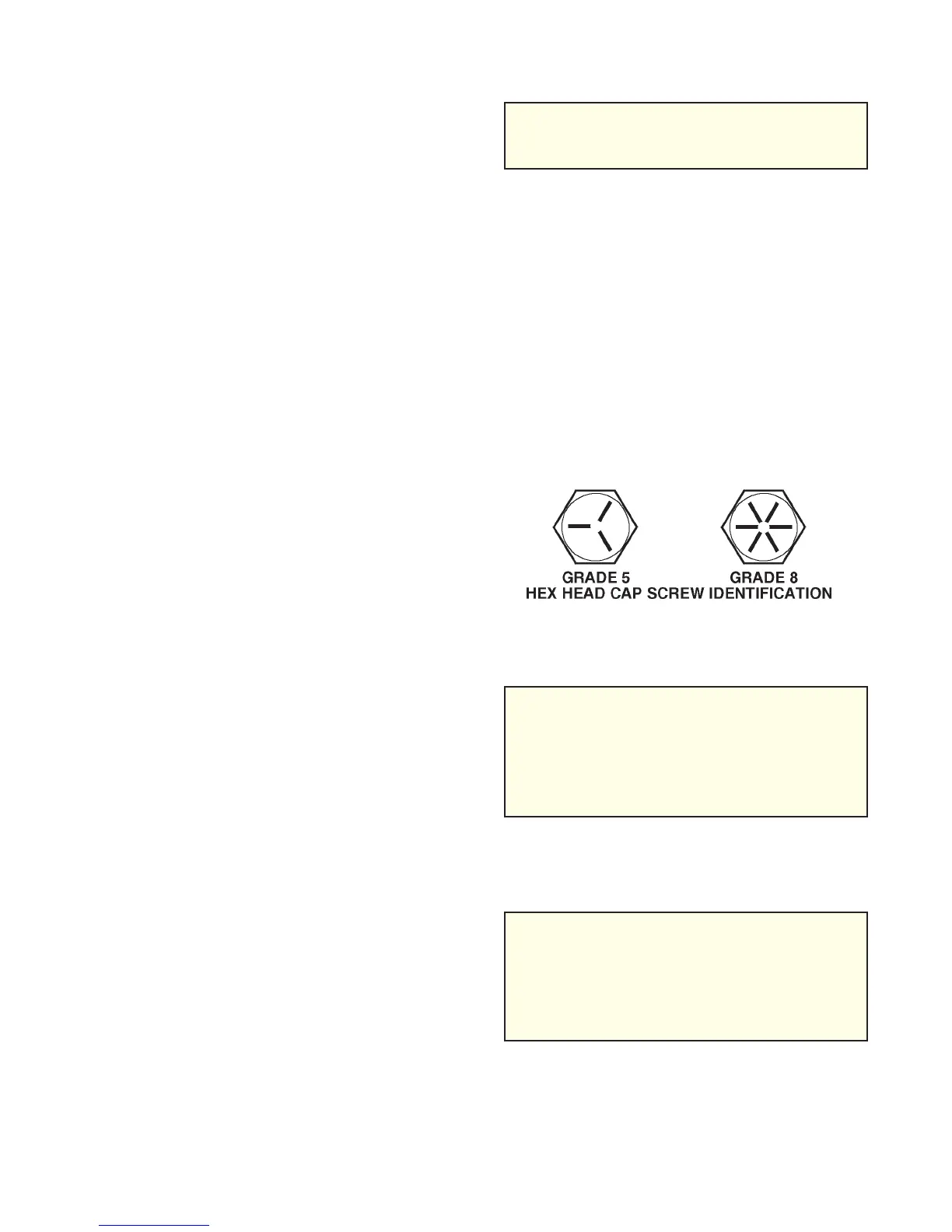

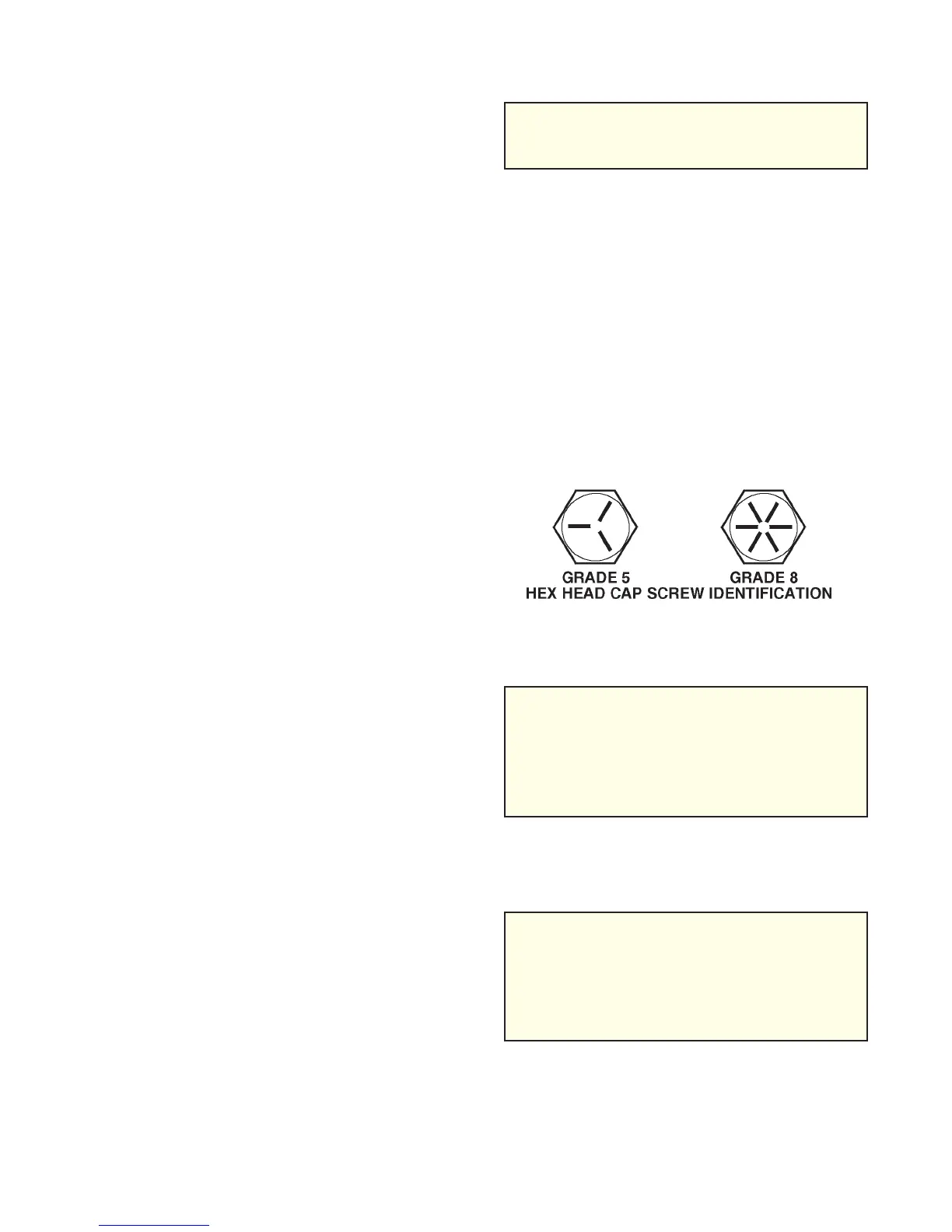

Identification of fastener grades is necessary.

When marked as a high grade bolt (grade 5, 8,

etc.) the mechanic must be aware he is working

with a highly stressed component, and the

fastener should be torqued accordingly.

Figure C-1: Fastener Grade

Identification

WARNING

USE OF FASTENERS OTHER THAN THE

GRADE SPECIFIED CAN CAUSE PER-

SONAL INJURY OR EQUIPMENT FAILURE.

IF A MOUNTING BOLT IS REMOVED,

ALWAYS REPLACE IT WITH A NEW BOLT

OF THE SAME GRADE.

When the maximum recommended torque

value has been exceeded, replace the fastener.

NOTE

TEMPERATURE VARIATION, VIBRATION,

AND METAL ELASTICITY CAN RESULT IN

THE GRADUAL REDUCTION OF BOLT

TORQUE. RE-TORQUE BOLTS AS

OUTLINED IN THE INSPECTION PROCE-

DURES.

20030115

Loading...

Loading...