99903514:TELESCOPIC CRANE: 3-15 SECTION 3: REPAIR20030115

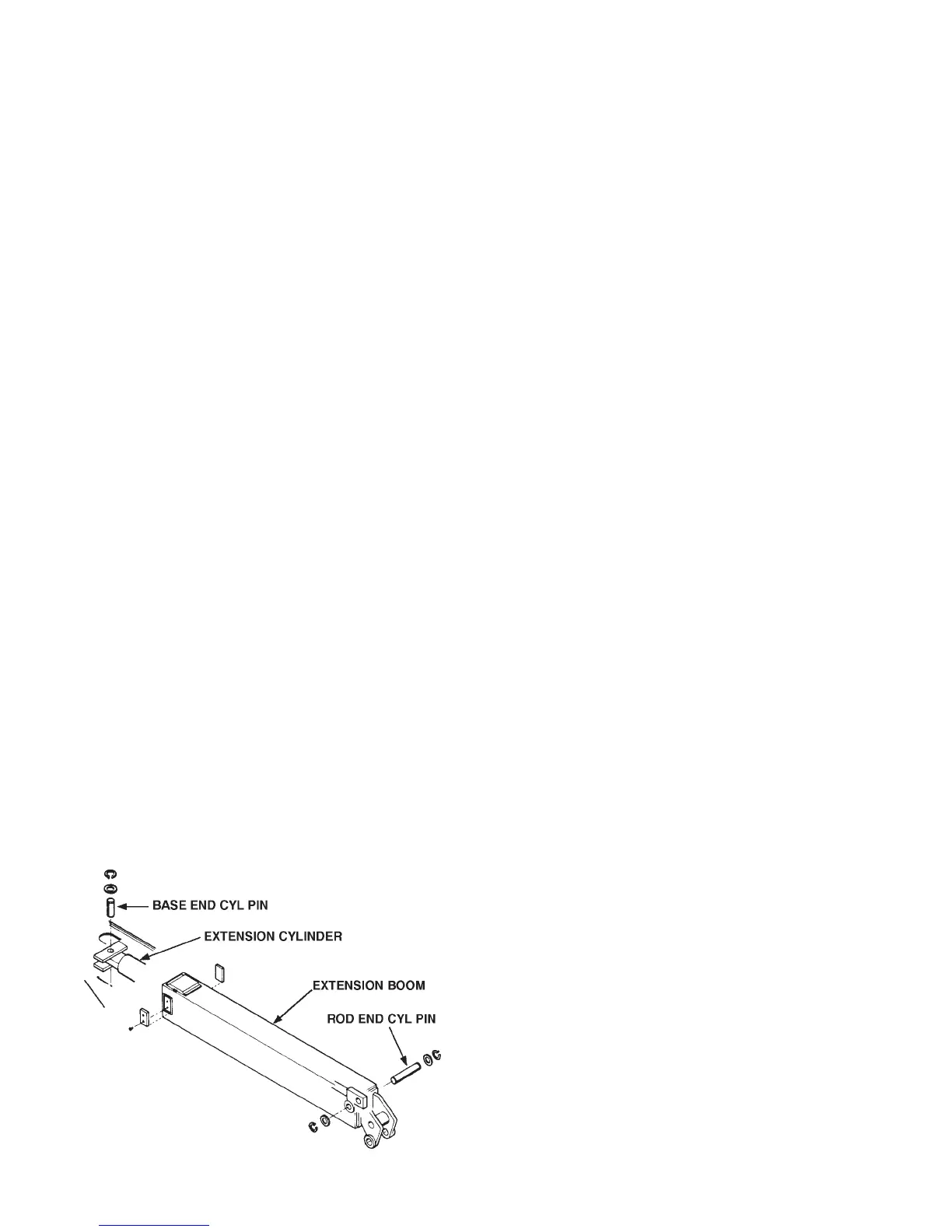

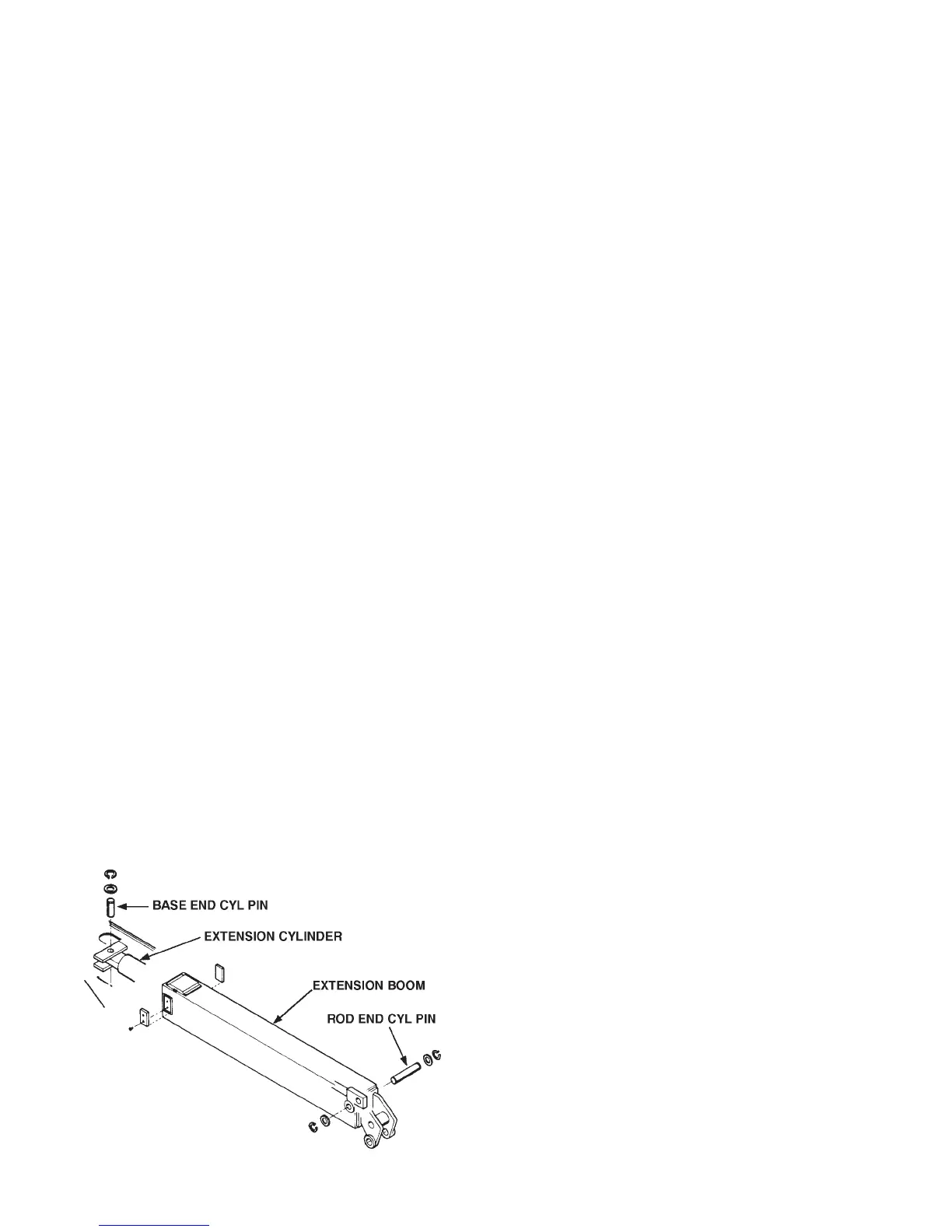

3-16: INTERNAL CYLINDER REMOVAL

AND REPLACEMENT

All telescopic crane models have internal

extension and/or main cylinders. To remove

and replace an internal cylinder,

1. Prior to beginning work on any crane cylin-

ders, completely support the base, mast

and booms.

2. Position the crane with the inner and exten-

sion booms in a horizontal position.

3. Retract the extension booms completely.

4. Disconnect and cap the extension cylinder

hydraulic hoses. Plug the hose ports.

5. Remove the cable from the sheaves at the

end of the bom tip.

6. Unfasten and move anti-two block wires on

the extension boom only.

7. Refer to the parts book to determine which

pins and fasteners secure the cylinders on

your crane.

In all cases, you must remove the extension

cylinder and extension boom at the same

time.

On crane models 3820 and 5020, there is a

pin which connects the mast to the lower

boom. To remove the extension cylinder,

slide this pin out just until the extension

cylinder is free, but DO NOT REMOVE IT

COMPLETELY! By keeping the pin in place,

the lower boom will remain connected to the

base.

Models including the 1015 and 2020 do not

have pins securing the cylinders, and you

must remove bolts or fasteners.

8. Remove the cylinder.

Reverse this procedure to replace the cylinder.

See section 3A: Cylinder Repair for information

on how to repair the cylinder.

3-17: LOWER BOOM REMOVAL AND

REPLACEMENT

1. Lower the lower boom completely. Support

the base, mast and boom prior to disassem-

bly.

2. Identify and disconnect hydraulic hoses.

Cap or plug all open hydraulic fittings.

3. Disconnect rod ends of inner boom hoist

cylinders. Position a block for cylinders to

rest against. Be careful not to pinch or pull

hydraulic hoses.

4. Position 2 fabric slings of adequate capacity

around lower boom and cinch slings on

opposite sides of center of gravity. Hook

slings on hoist and raise hoist to tension the

sling.

5. Remove cap screw and retainer from inner

boom pivot pin. With aid of a heavy sledge

hammer and pin driving tool, remove the

inner boom and lay down on a firm work

support.

3-18: WIRE ROPE REMOVAL/REPLACE-

MENT

The maintenance section of this manual de-

scribes inspection criteria for wire rope. If the

wire rope is damaged, bent, or worn as defined

in Section 2-6, replace it using the following

steps:

1. Run out all wire rope from the winch, and

stretch it out straight. Disconnect the rope

from the cable guide on the side of the lower

boom.

2. Remove the clamp which secures the rope

to the boom tip. Pull the pin to release the

cable.

3. Unhook the wire rope from the winch spool

by removing the set screw or cable wedge

anchor.

4. Remove the wire rope.

Figure C-15: Internal Extension Cylinder

Loading...

Loading...