99903514:TELESCOPIC CRANE: 3-10 SECTION 3: REPAIR

Pins

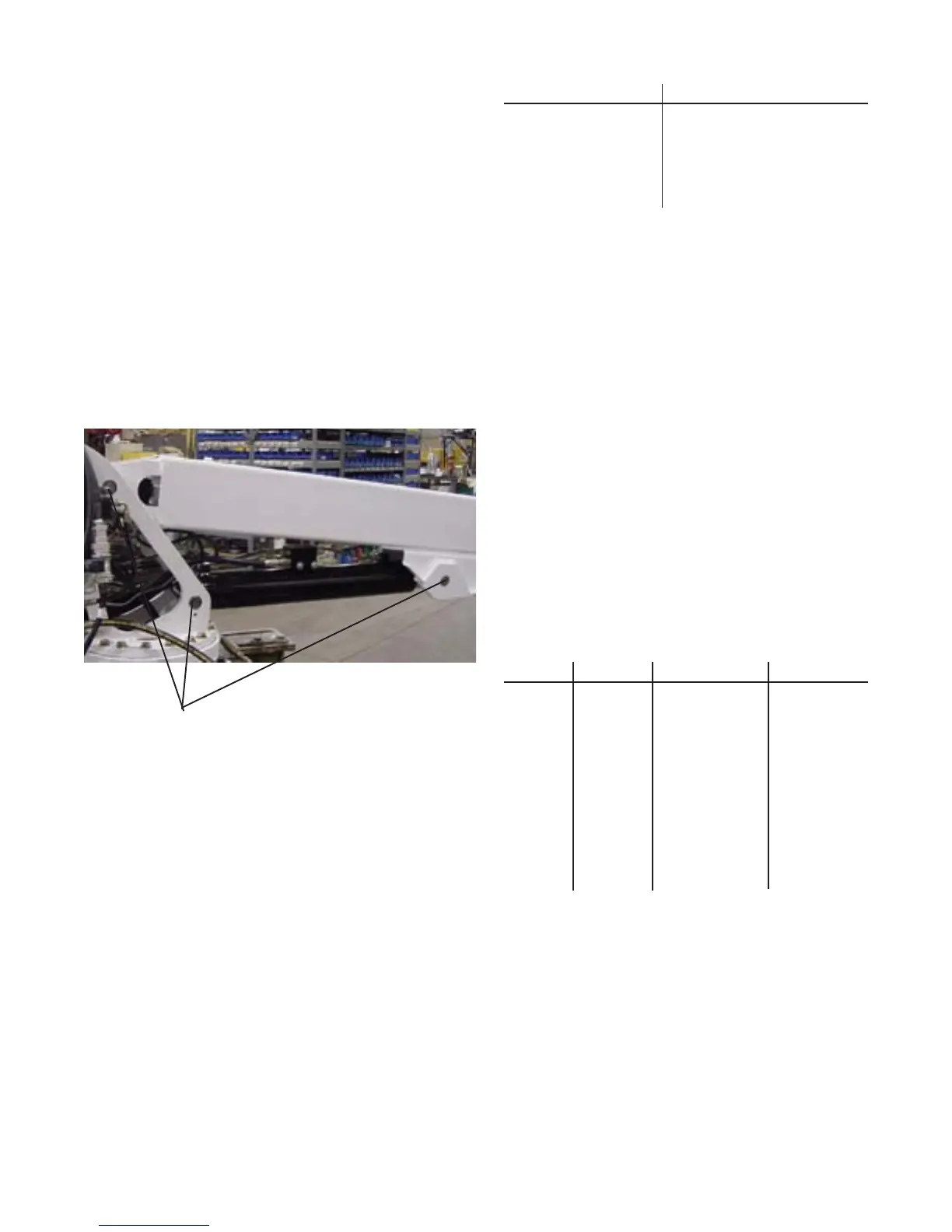

Figure C-11: Pin Locations

3-11: PINS

Pins are frequently used as structural compo-

nents on telescopic cranes. Critical structural

pins which require inspection and repair include:

Pin which secures the lower boom assem-

bly to the mast

Pin which secures the main cylinder base

end to the mast

Pin which secures the main cylinder rod end

to the lower boom assembly

Pin which secures the extension boom

assembly to the boom tip.

See Figure C-11 for the pins which secure the

lower boom to the mast, the cylinder base to the

mast, and the cylinder rod to the lower boom.

Every two years, disassemble the crane and

inspect the critical structural pins (noted above)

for damage.

To remove the pins:

1. Support crane assemblies using a hoist or

two slings.

2. Remove pin.

3. Check for signs of wear. The pin should be

shiny with no galling or pitting in the contact

areas. Minor blemishes (see chart) can be

dressed and the pins can be reused. Pins

with cracks which extend into the pin cross

section must be replaced.

4. Reinstall pins. Use anti-seize to aid installa-

tion. Grease as needed.

Pin Defect Maximum Tolerance

Nick, gouge, or Up to 1/8” diameter

scratch

Circular scratch Up to 1/16” wide or deep

around the pin

Lengthwise scratch Up to 1/32” wide or deep

Pins with defects up to the maximum tolerance

can be repaired. To repair, dress the edges of

the flaw with a file so no metal protrudes above

the circular surface of the pin.

Pins with defects larger than those listed, or

with large cracks extending into the pin cross

section, must be replaced.

3-12: BEARINGS & BUSHINGS

3-12-1: BEARING TYPES

Roller bearings are used on sheaves in the

1007, 1015 and 2020 cranes.

Bushings, which are bearings without moving

parts, are used on the cylinders and booms of

some crane models. See chart for bushing

locations.

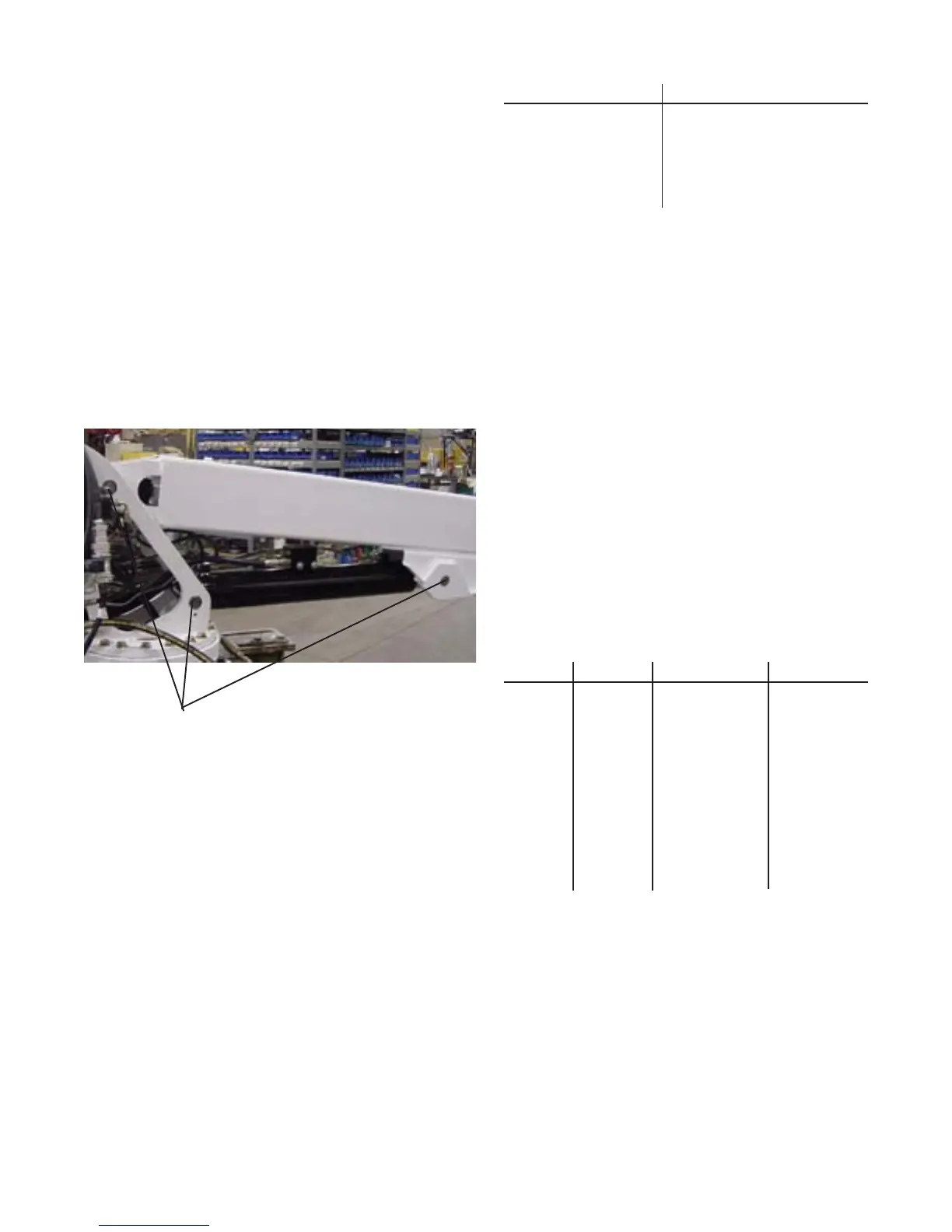

BUSHING LOCATIONS

MODEL MAST CYLINDER BOOMS

1015 No No No

2020 No Yes Yes

3020 No Yes No

3820 No Yes No

5020 No Yes No

5525 No Yes Yes

6025 No Yes Yes

6625 No Yes Yes

7020 No Yes Yes

7025 No Yes Yes

3-12-2: BEARING INSPECTION & RE-

PLACEMENT

To inspect bushings and bearings,

1. Degrease bearing.

2. Inspect the inside coating of the bearing. No

tears and breaks in the coating are accept-

able.

3. Inspect the metallic body of the bearing. No

change in the bearing dimensions are

permitted.

20030115

Loading...

Loading...