99903514:TELESCOPIC CRANE: 3-14 SECTION 3: REPAIR

DANGER

SUPPORT THE CRANE BASE, MAST, AND

BOOMS PRIOR TO REMOVING ANY CYLIN-

DERS! FAILURE TO SUPPORT THE CRANE

FULLY CAN CAUSE PERSONAL INJURY AND

EQUIPMENT DAMAGE.

3-14: LOWER CYLINDER REMOVAL &

REPLACEMENT

Replace the lower cylinder if it leaks or is bent or

damaged. To replace the cylinder:

1. Operate lower boom control levers to

position the lower boom as low as possible.

Support the boom using a hoist or two

slings, and make sure the mast and base

are fully supported.

2. Identify and remove hose connections. Cap

or plug all open hydraulic fittings, and dis-

connect anti-two block wires.

3. Position a fabric sling of adequate capacity

around lower cylinder and cinch sling near

rod end such that sling will lift cylinder in

vertical position. Hook sling on hoist and

raise hoist to tension the sling.

4. Remove and discard retaining bolt from rod

end of cylinder.

5. Remove and discard retaining bolt and

keeper plate from piston end of cylinder.

With aid of a heavy sledge hammer and pin

driving tool, drive piston end pin from mast.

Position cylinder on a firm work support.

6. Reverse procedure for reassembly. Rein-

stall pins using anti-sieze for ease of as-

sembly. Torque new threaded fasteners per

Torque Data Charts in the general reference

section.

7. Start the crane and slowly cycle lower boom

hoist cylinder out and in with no load to

purge air from the system.

8. After the air has been purged from the

system, check the reservoir oil level. Top off

if necessary.

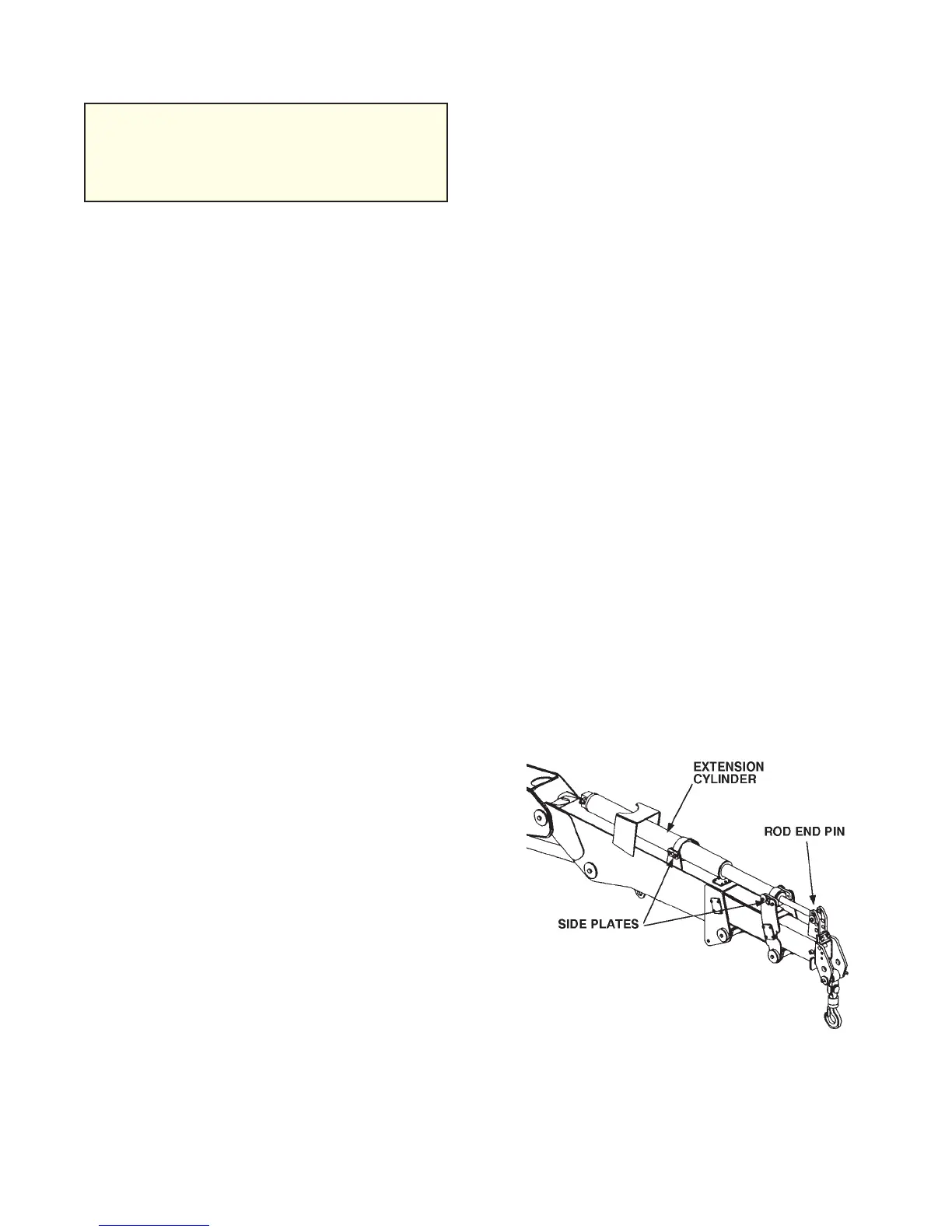

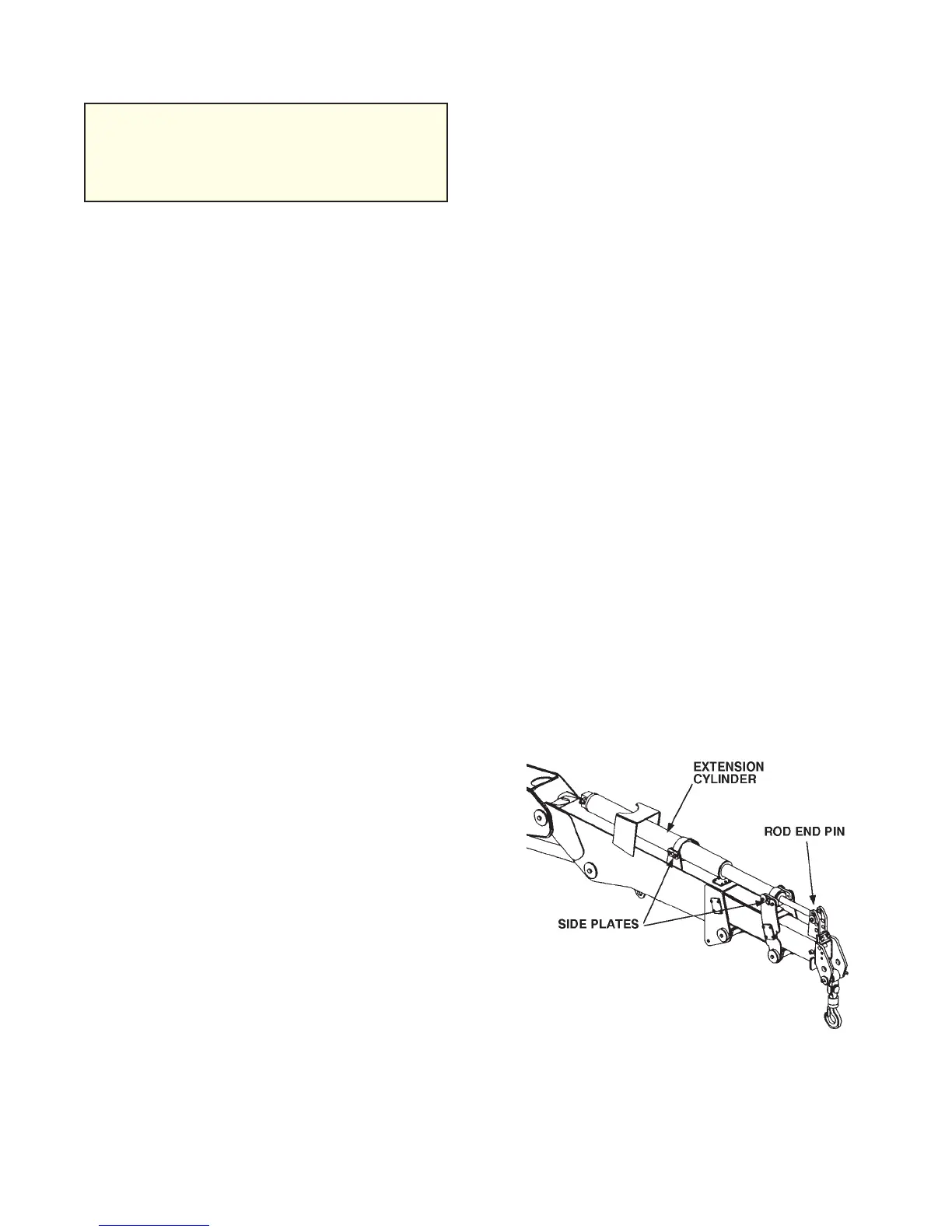

3-15: EXTERNAL EXTENSION CYLIN-

DER-REMOVAL AND REPLACEMENT

Models 1015, and 2020 telescopic cranes have

external extension cylinders. See Figure C-14

for identification. To remove and replace a

telescopic crane cylinder:

1. Position the crane with the lower and exten-

sion booms horizontal. Support the base,

mast and boom.

2. Disconnect and cap the extension cylinder

hydraulic hoses. Plug the hose ports.

3. Remove and discard bolts securing the

wear pad retainer plates. Remove the

plates and wear pads.

4. Remove the retaining ring, bushing, and pin

which secure the rod end of the cylinder to

the boom.

5. Using a sling or hoist, lift the external exten-

sion cylinder and remove.

To install an external extension cylinder:

1. Using fabric slings and hoist, position the

cylinder atop the extension boom. The

extension boom may have to be moved

manually to align the rod of the cylinder with

the ears of the extension boom. Once

aligned, insert and secure pin.

2. Install the side plates securing the cylinder

to the outer boom. Torque fasteners per

Torque Data Chart.

Figure C-14: External Extension Cylinder

20030115

Loading...

Loading...