6-13 SECTION 6. GENERAL REFERENCE99903514:TELESCOPIC CRANE: 20030115

TIGHTENING PROCEDURE:

1. Refer to the Torque Data Chart to determine the proper torque value to apply to the size of capscrew

used.

2. Follow the tightening sequence shown in the diagram. Note that the quantity of capscrews may differ

from the diagram, but the sequence must follow the criss-cross pattern as shown in the diagram.

3. Torque all capscrews to approximately 40% of the specified torque value, by following the sequence.

(EXAMPLE: .40 x 265 FT-LBS = 106 FT-LBS)

(EXAMPLE-METRIC: .40 x 36 KG-M = 14.4 KG-M)

4. Repeat Step 3, but torquing all capscrews to 75% of the specified torque value. Continue to follow the

tightening sequence.

(EXAMPLE: .75 x 265 FT-LBS = 199 FT-LBS)

(EXAMPLE-METRIC: .75 x 36 KG-M = 27 KG-M)

5. Using the proper sequence, torque all capscrews to the listed torque value as determined from the

Torque Data Chart.

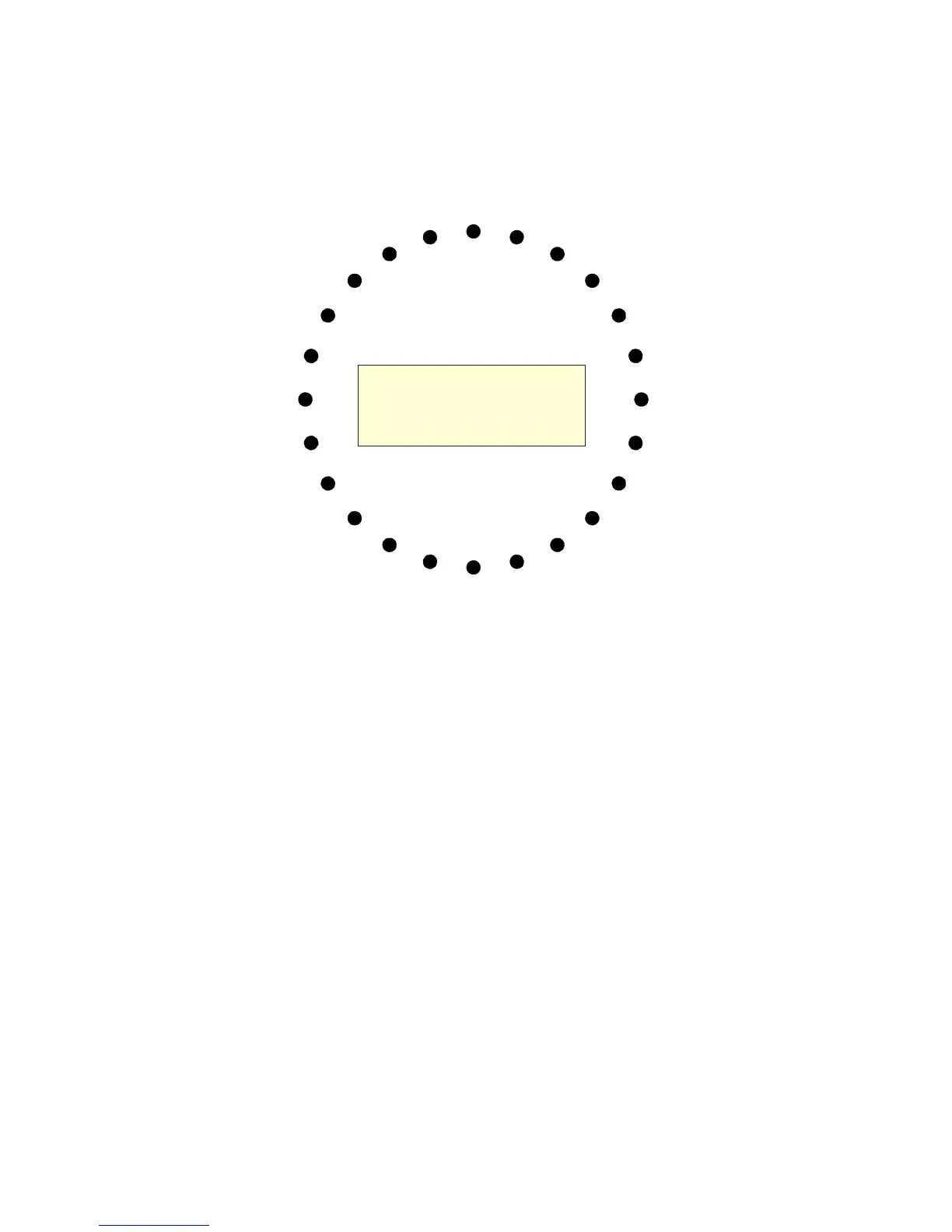

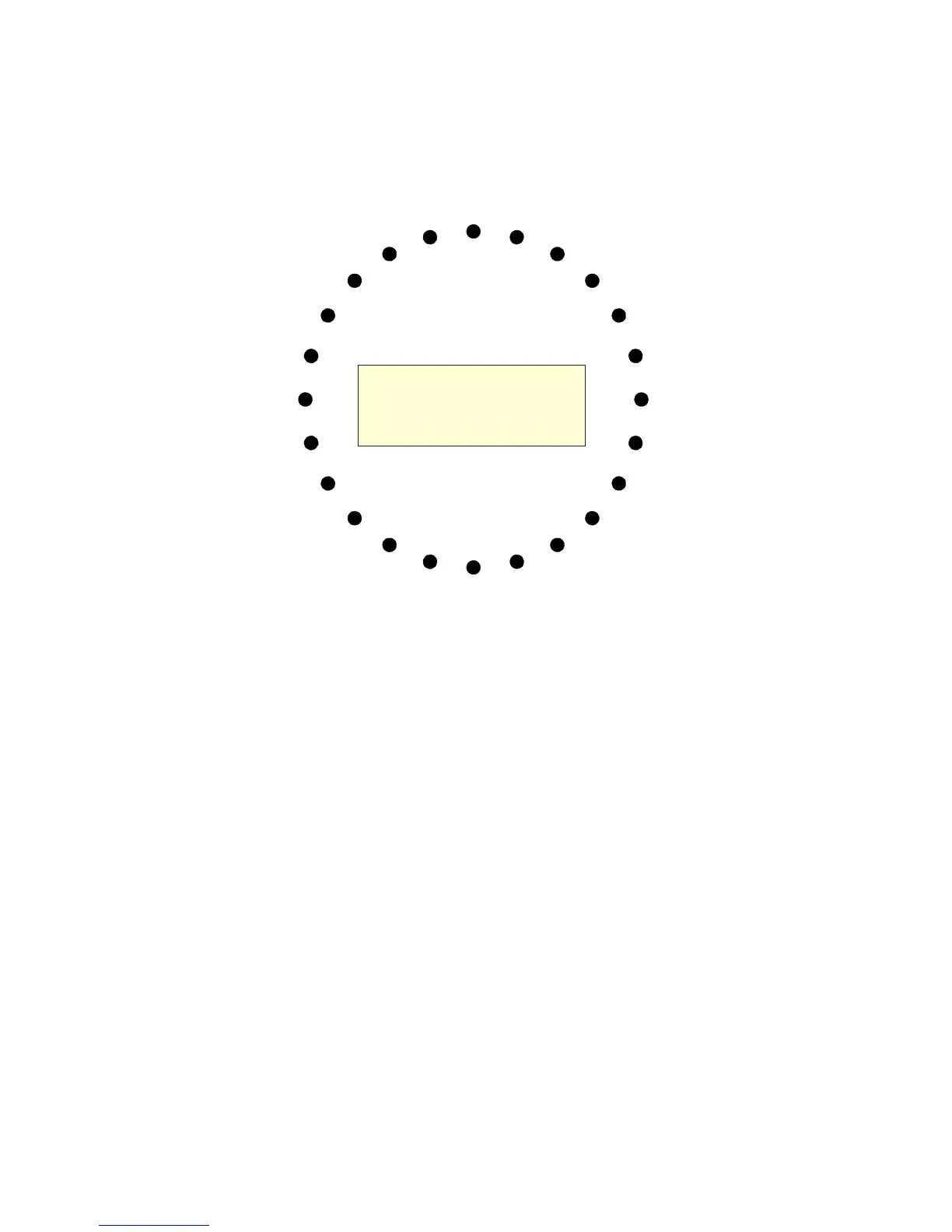

TURNTABLE BEARING FASTENER TIGHTENING SEQUENCE

Refer to the diagram below for proper tightening/torquing sequence of the turntable bearing to the crane

base and crane mast. The total quantity of cap screws varies dependent on crane model.

WARNING

Number 1 can be assigned to

any capscrew if the sequence

remains the same in reference

to number 1.

3

7

11

15

19

23

1

5

9

13

17

21

4

8

12

16

20

24

2

6

10

14

18

22

Loading...

Loading...