99903514:TELESCOPIC CRANE: 3-11 SECTION 3: REPAIR

4. Replace the bearing if needed. Otherwise,

lightly grease and reassemble.

To replace bearings:

1. Start the bearing in its respective hole by

rotating the bearing while applying pressure.

Align the grease zerk hole with the bearing

hole (if applicable). Once started, drive the

bearing to its full counterbored depth by

tapping with a rubber mallet. Use a mallet

with a head larger than the bearing so the

bearing isn’t damaged.

2. If the bearing is loose, tighten the bearing by

centerpunching the bore diameter in about

50 places around the 2” deep bored area.

3. After installing bearings , and before assem-

bling the machine, insert the pins through

both bearings in each end of the lift cylin-

ders, and through the boom pivot bearings,

to ensure alignment and fit are correct. Pins

should slide freely through the leading hole

and start in the opposite hole. If the pin

binds, do not force it. Remove the pin, clean

the hole, and reinsert.

Inspect bushings and bearings as needed, and

replace any damaged or worn bushings. Lubri-

cate with EP grease upon replacement.

3-13: VALVEBANK

3-13-1: VALVEBANK COMPONENTS

This section describes the operating character-

istics of the main control valvebank used tele-

scopic cranes and provides troubleshooting

information.

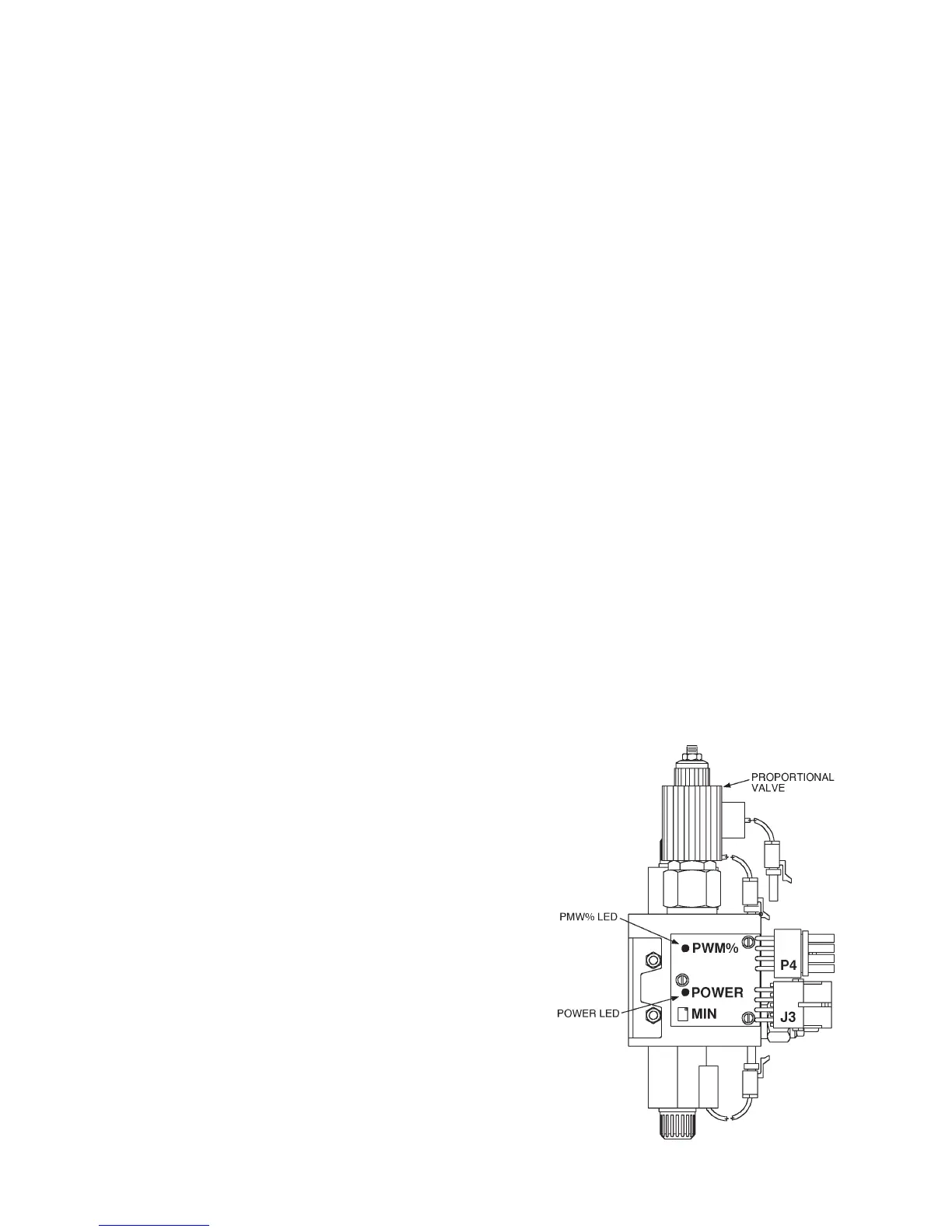

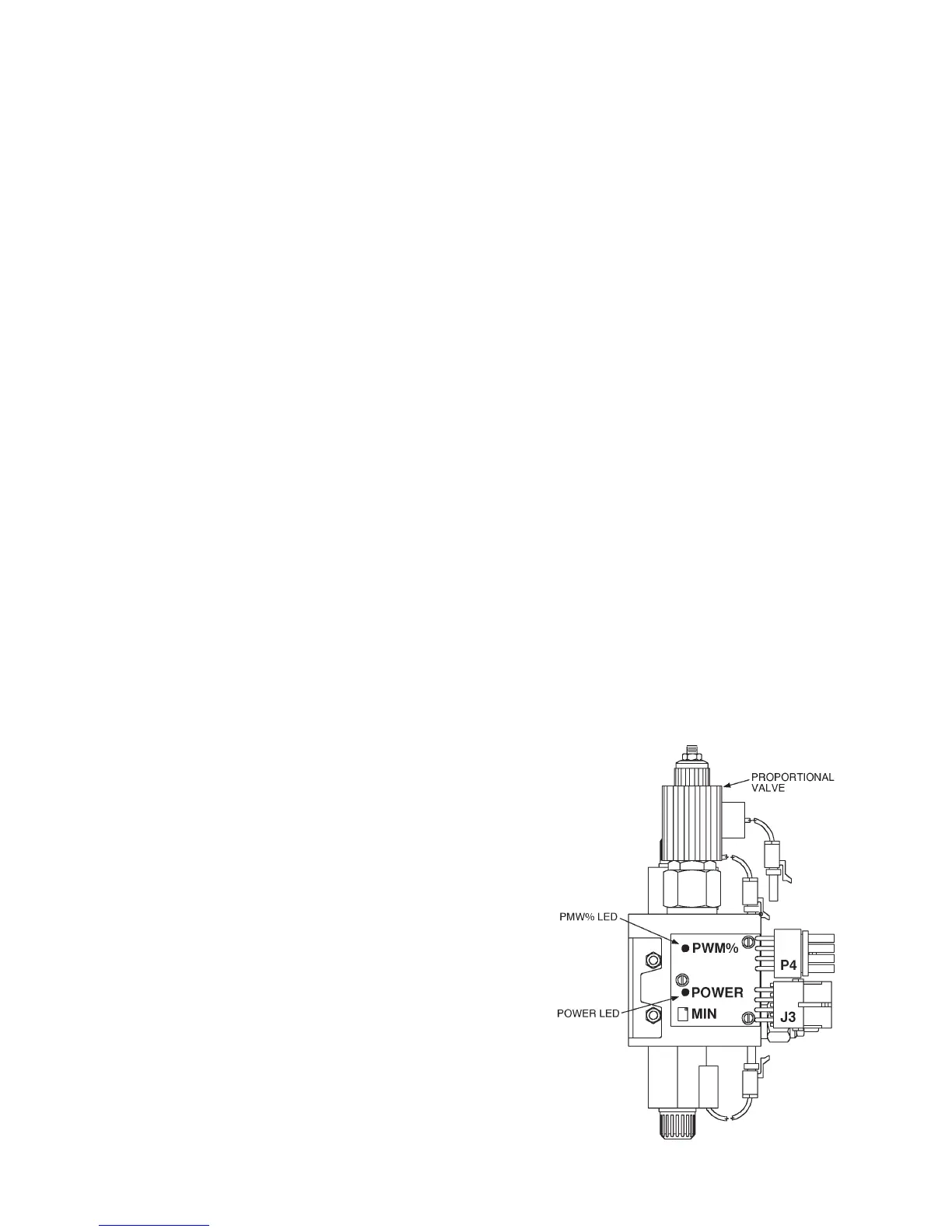

ELECTRICAL-AMP DRIVER

POWER LED

The Power LED illuminates red while power is

being applied to the valve amplifier. If the LED is

not illuminated, no power is being applied to the

valve amplifier.

If the Power LED does not function as de-

scribed, inspect input wiring and repair or

replace as necessary. When input power is

applied, the LED should illuminate.

Figure C-12: Valve Functions

PMW% LED

The PMW% LED indicates the condition of the

output current flowing to the proportional valve.

The LED will change colors from red to yellow

to green. The change of colors indicates the

variance of current flowing to the proportional

valve. Red indicates minimum current and

green indicates maximum current. This repre-

sents the flow condition going from low flow

(red) to maximum flow (green), thus varying the

speed of crane functions.

If the LED stays red when the speed control

trigger is activated, a dead short is present in

the circuit. This could be the result of a wiring

problem, shorted out proportional coil, etc.

Inspect the wiring and replace the proportional

coil if required.

MIN POTENTIOMETER

The MIN adjustment potentiometer is used to

set the minimum amount of movement of an

individual function at the valvebank when the

corresponding function switch at the handset is

depressed. To adjust, set engine at high speed

control setting. Depress the “Rotation” function

switch at the handset. Adjust the MIN potenti-

ometer at the AMP driver card clockwise until

crane begins to rotate or counterclockwise until

motion begins to stop. No other electrical

adjustments are required to properly operate the

crane.

20030115

Loading...

Loading...