6-14 SECTION 6. GENERAL REFERENCE99903514:TELESCOPIC CRANE: 20120104

Before a bearing is removed from a crane for

inspection, one of the following conditions should be

evident:

1. Metal particles present in the bearing

lubricant.

2. Increased drive power required to rotate the

crane.

3. Noise emitting from the bearing during crane

rotation.

4. Rough crane rotation.

5. Uneven or excessive wear between the pinion

gear and turntable gear.

TURNTABLE BEARING INSPECTION FOR REPLACEMENT

If none of the above conditions exists, the bearing is

functioning properly and need not be replaced. But, if

one or more of the above conditions exists, inspection

may be required. Limits are measured in “TILT”

which is dependent on the internal clearances of the

bearing. TILT is the most practical determination of a

bearings internal clearance once mounted on a crane.

Periodic readings indicating a steady increase in TILT

may be an indicator of bearing wear. Note that a

bearing found to have no raceway cracks or other

structural irregularities should be reassembled and

returned to service.

NOTE

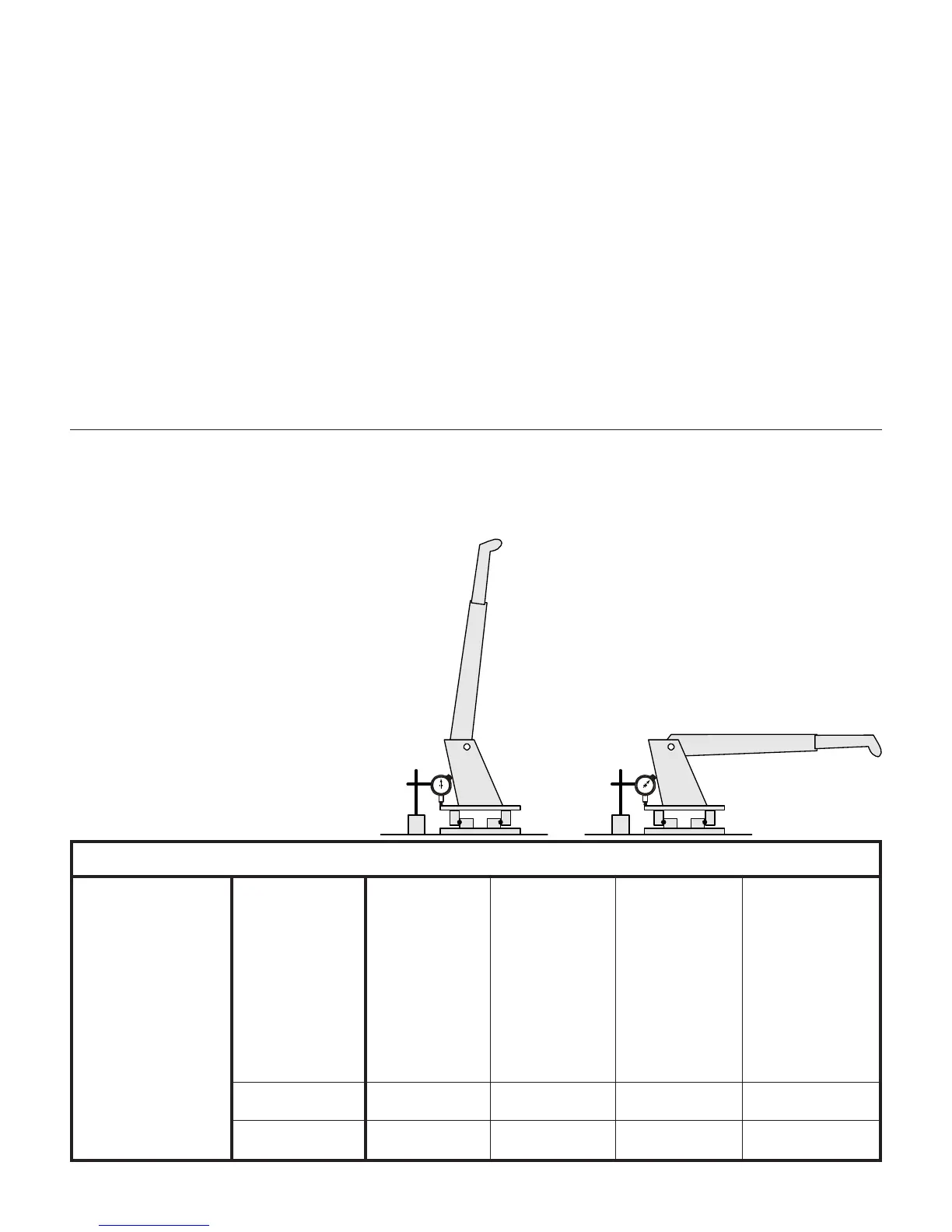

THE FIGURES LISTED IN

THIS CHART ARE

SERVICE GUIDELINES

AND DO NOT, IN

THEMSELVES, REQUIRE

THAT THE BEARING BE

INSPECTED.

IF THERE IS REASON

TO SUSPECT AN

EXCESS OF BEARING

WEAR AND THE

MEASURED TILT

DIMENSION EXCEEDS

THE DIMENSION

LISTED, REMOVE THE

BEARING FOR

INSPECTION.

IMT

CRANE,

LOADER

OR

TIREHAND

MODEL

BALL DIA.

(REF)

TILT DIM.

(A

1

-A

2

)

.060”

(1.524mm)

.070”

(1.778mm)

.075”

(1.905mm)

.090”

(2.286mm)

.875”

(22mm)

1.00”

(25mm)

1.18”-1.25”

(30-32mm)

1.75”

(44mm)

1007

1014

1014A

1015

2015/2020

2109

3000

3816/3820

3016/3020

421/425

4300

5016/5020

6016/6020

TH7 BODY ROT’N

TH1449 BODY ROT’N

TH15B CLAMP

TH2551B CLAMP

TH2557A CLAMP

5200

5200R

5217

5800

7020

7025

7200

7415

9000

TH10 BODY ROT’N

TH14 BODY ROT’N

16000

32018

32027

32030

T30

T40

9800

12916

13031

13034

14000

15000

18000

20017

8000L

H1200

H1200RR

T50

TH2551B BODY ROT’N

TH2557B BODY ROT’N

TH2557A BODY ROT’N

COMPARISON CHART - MODEL TO MEASURED TILT DIMENSION

TEST PROCEDURE

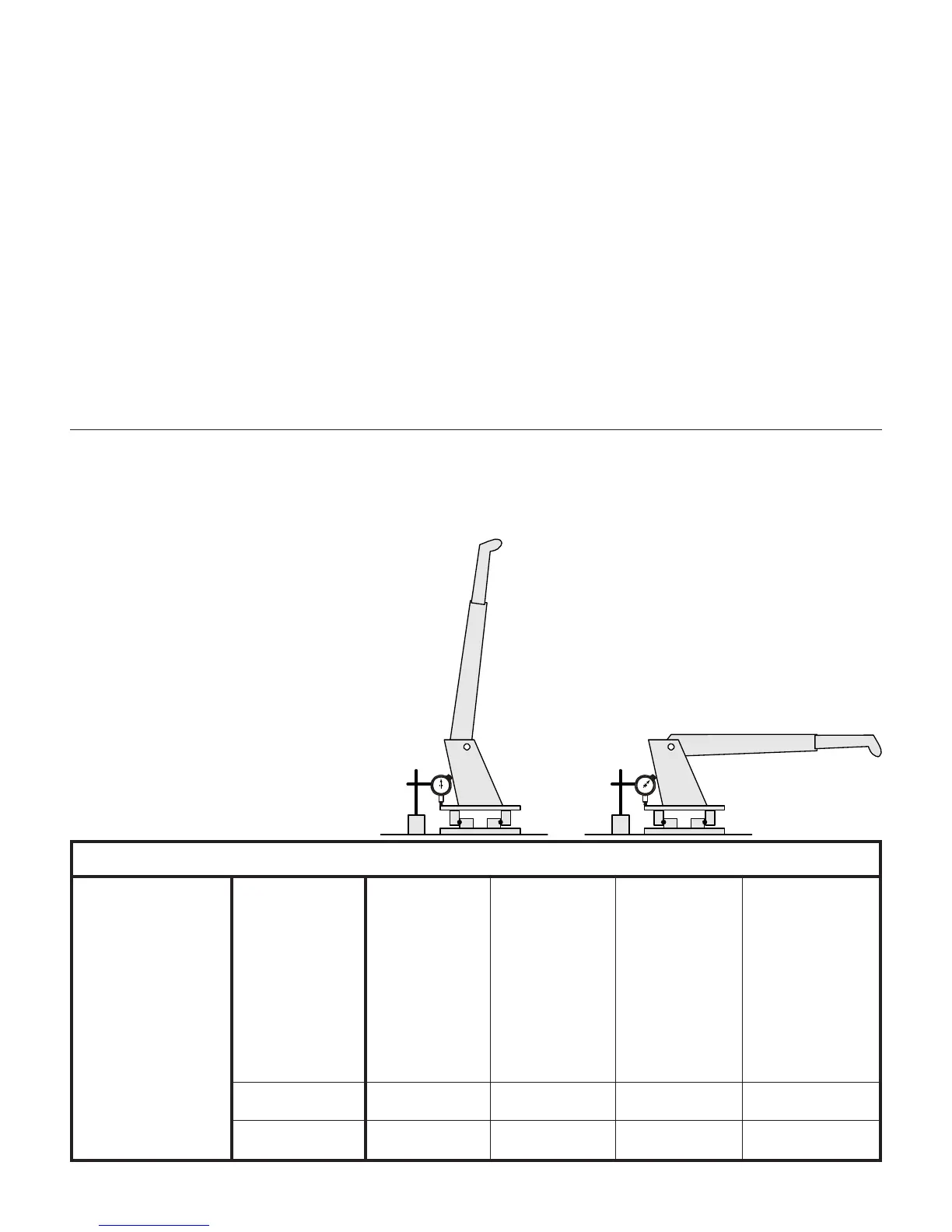

1. Place crane in vertical position.

2. Set a dial indicator at 0 on the pinion cover plate at

back side of mast.

3. Lower crane to the horizontal position.

4. Check and record the dial indicator change. It

should not exceed the tilt measurement noted in

the chart below.

5. Return the crane to the vertical position. The dial

indicator should return to 0.

Set up dial indicator

to 0" on pinion cover

at back side of mast.

Lower crane to

horizontal position.

Read dial indicator.

Loading...

Loading...