6-7 SECTION 6. GENERAL REFERENCE99903514:TELESCOPIC CRANE: 20120104

STABILITY TEST

Every IMT factory-installed crane includes a

completed stability chart. Any installer other than

IMT also has the responsibility to complete a

stability chart. Cranes are tested for stability to

85% of “tipping”, where the crane load is balanced

with the truck, and any additional load would result

in tipping. The Stability Test is per SAE J765a.

Figures entered on the stability chart are for a

specific truck and crane combination. If the crane

or vehicle are modified or replaced with another, it

is necessary to recalculate stability. By referring

to the stability chart for your crane/chassis combi-

nation, it is possible to determine the loads per-

mitted in the derated load range of your crane.

CAUTION

THE PERCENTAGES GIVEN IN THE GRAY AREA

OF THE STABILITY CHART ARE BASED ON

ACTUAL VEHICLE STABILITY AND DO NOT TAKE

FRONT AXLE RATING INTO CONSIDERATION. DUE

TO THE CAPACITY RATING OF THE FRONT AXLE,

THE LOADING 75° TO EITHER SIDE OF THE

CENTERLINE OVER THE CAB MUST BE

SEVERELY RESTRICTED.

Determine the stability of your truck and crane

combination per the following procedure:

1) Use Figure F-2: Stability Chart - Crane

Mounted Behind Cab for cranes mounted directly

behind the chassis cab, and use Figure F-3:

Stability Chart -Rear Mounted Crane for cranes

mounted at the rear of the chassis.

2) On the appropriate figure, fill out items A

through L.

3) Perform the stability test on a flat hard surface.

Ideally this surface will be concrete, but asphalt or

hard-packed gravel are acceptable. Only autho-

rized testing personnel may be in or near the test

area. Per SAE J765a, the area must be within 1%

of level.

4) Position and lower the stabilizers until the

weight of the crane has been removed from the

truck springs.

5) Extend the crane to full horizontal position,

centered over the rear of the truck.

6) From the capacity placard, determine the rated

load at the maximum horizontal reach. Place a

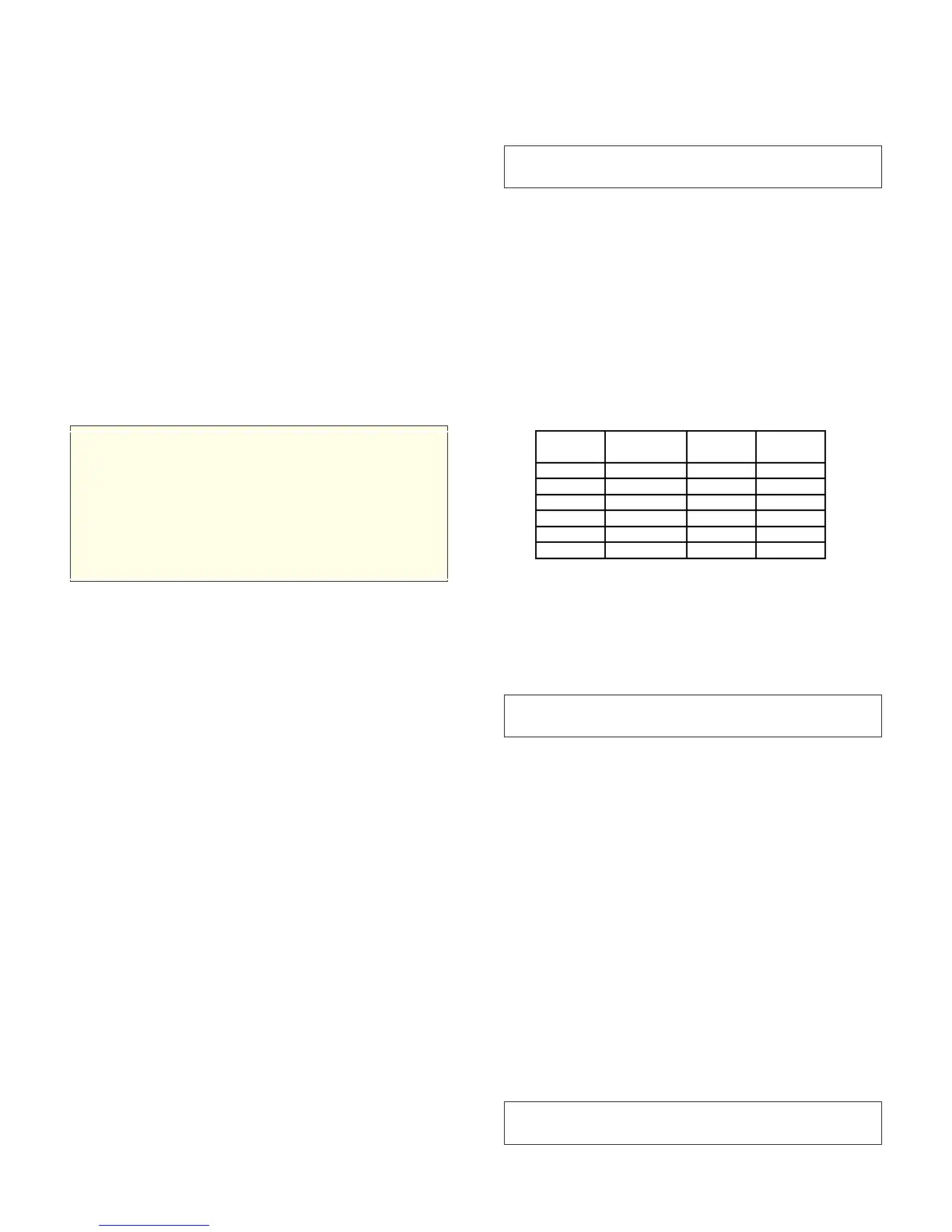

1 30 7 150

2 60 8 120

390990

4 120 10 60

5 150 11 30

6 180 12 0

CLOCK

POS.

DEGREES

(º)

CLOCK

POS.

DEGREES

(º)

weight equal to 118% of that rated load at the

maximum horizontal reach (L). Keep the load

close to the ground to avoid excessive tipping.

L = ft.

7) Slowly start rotating the load counterclockwise.

Through every 5° increment, check whether all

vehicle tires remain in contact with the test sur-

face.

NOTE: To make it easier to visualize degrees,

compare the rotation to numbered positions on a

clock face. As a point of reference, the rear

center of the truck is the 0° (12 o’clock) position,

and the front center is the 180° (6 o’clock) posi-

tion.

8) If at any point through the rotation cycle, any

one of the vehicle tires starts to break contact with

the test surface, stop the rotation and note the

position of the crane (X°). This is the balance

point which determines 85% of tipping for the

rated load.

X° =

9) After the balance point has been reached,

retract the extension boom until all tires are in full

contact with the test surface again.

10) Continue rotating the boom after stability has

been regained. Again, watch all vehicle tires for a

point of instability. If a point of instability reoccurs

(one of the vehicle tires breaks contact with the

test surface), retract the extension boom until

stability is regained.

11) Repeat this cycle through a full 180°.

12) At the end of the 180° arc, physically measure

the existing horizontal distance from the centerline

of rotation to the centerline of the load (K).

K = ft.

Loading...

Loading...