Chapter 5 General Reference 123

Turntable Bearing Inspection for Replacement

Before a bearing is removed from a crane for inspection, one of the following conditions should

be evident:

1 Metal particles present in the bearing lubricant.

2 Increased drive power required to rotate the crane.

3 Noise emitting from the bearing during crane rotation.

4 Rough crane rotation.

5 Uneven or excessive wear between the pinion gear and turntable gear.

If none of the listed conditions exists, the bearing is functioning properly and need not be

replaced. But, if one or more of the above conditions exists, inspection may be required. Limits

are measured in “TILT” which is dependent on the internal clearances of the bearing. TILT is the

most practical determination of a bearings internal clearance once mounted on a crane.

Periodic readings indicating a steady increase in TILT may be an indicator of bearing wear.

Note that a bearing found to have no raceway cracks or other structural irregularities should be

reassembled and returned to service.

Turntable Bearing Tilt Test

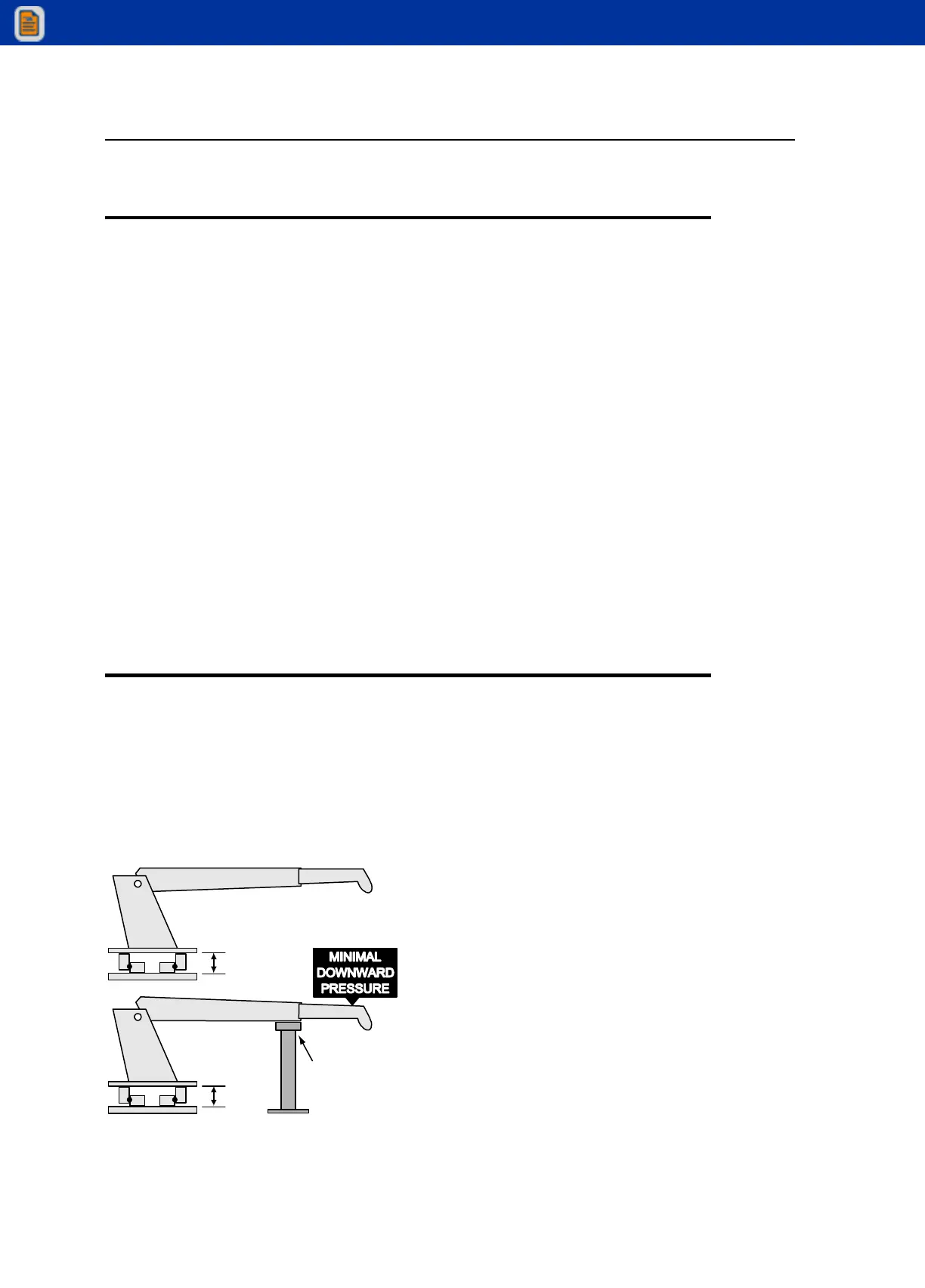

1 With the crane horizontal and fully extended, measure between the top and bottom mounting

surfaces of the turntable bearing (A1), using a dial indicator for accuracy.

2 Reverse the load by applying minimal downward pressure on the boom while the boom is in

the boom support or on a solid surface. Again measure A2.

3 Subtract A1 from A2 to determine tilt and compare the result with the accompanying chart.

A1

A2

Boom Suppor

Loading...

Loading...