- 30 -

2 Installation

2

Item Description

Oil and moisture

countermeasures

● Do not immerse the servo motor and cables into oil or water during use.

● ConrmtheIPratingoftheservomotorwhenusingitinaplacewithwaterdroplets.

(Except for the through shaft section)

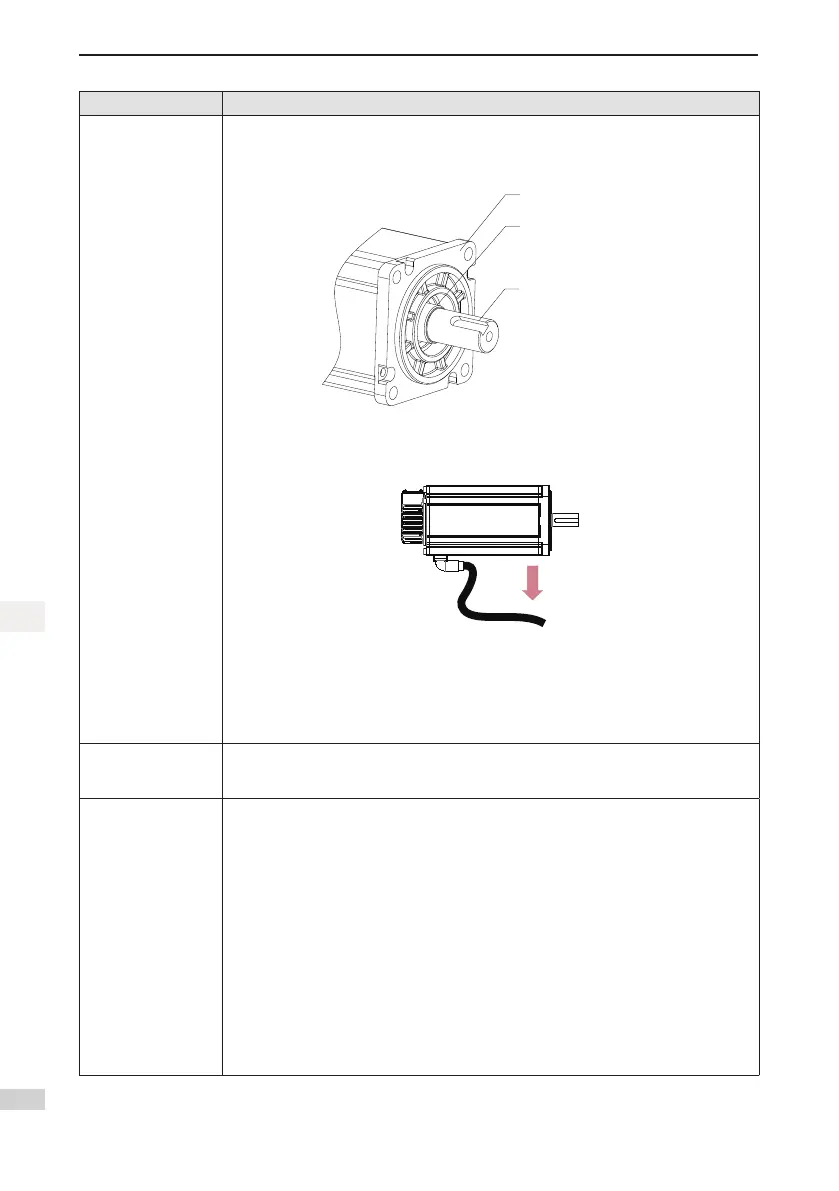

Flange face

The section though the shaft

is the part of the shaft that

protrudes from the motor

head face

Drive shaft

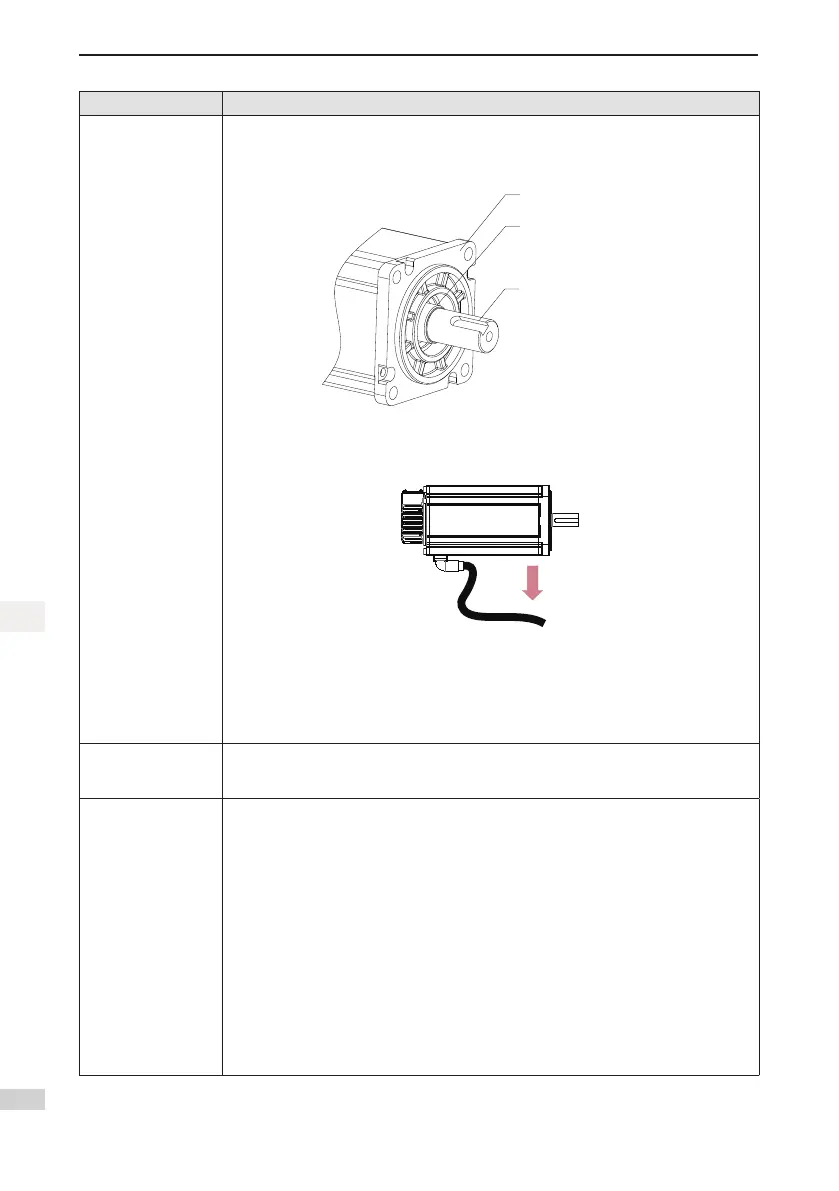

● Installthemotorwithitscableconnectionportsfacingdownward(asshowninthegure

below)whenthemotorisinstalledinaplacewherethereisliquid,toavoidliquidowing

along the cable to the motor body.

● In an environment where the through shaft section is exposed to oil drops, use a servo

motor with oil seal.

● Observethefollowingconditionswhenusingtheservomotorwithoilseal:

● Makesurethattheoillevelislowerthantheoilseallipduringuse;

● Avoid oil accumulation at the oil seal lip when the motor is installed vertically upward.

Stress of cables

Do not bend the cables or the pull the cables tight. In particular, do not pull the thin signal

cablesduringcablingandoperatingasthecorewiresareextremelyne(0.2mmor0.3

mm).

Connectors

● Observethefollowingprecautions:

● Whenconnectingtheconnectors,makesurethatthereisnoforeignmattersuchas

waste or sheet metal inside the connectors.

● Connecttheconnectorstothemaincircuitsideoftheservomotorrst,andmakesure

that the grounding cable of the main circuit cables is reliably connected. If the connectors

arerstconnectedtotheencodercableside,theencodermaybecomefaultyduetothe

potential differences between PEs.

● Makesurethepinsarecorrectlyarrangedduringwiring.

● Theconnectorsaremadeupofresins.Donotstriketheconnectorstopreventthem

from being damaged.

● Hold the servo motor body during transportation when the cables are well connected,

instead of catching the cables. Otherwise, the connectors may be damaged or the

cablesmaybebroken.

● Do not apply stress to the connectors during wiring if bent cables are used Failure to

comply may cause damage to the connectors.

Loading...

Loading...