Chapter 3: Additional System Details

42 M47-17028-EN

Servo manifold assembly

A standard servo manifold (7, Figure 17) includes the following components. Refer to Table 4 for the

function of each component.

• A servo valve

• An oil filter

• A system pressure gauge

• A dump valve

• An idle pressure valve

• A system relief valve

Crosshead motor manifold

The crosshead motor manifold is located in the frame base. The manifold routes oil to the motor for the

adjustable crosshead. A three-position valve in the manifold provides control of the oil flow from the

manifold to the motor. The three-position valve is controlled by the operator through the crosshead up/

down switch on the front panel of the frame base.

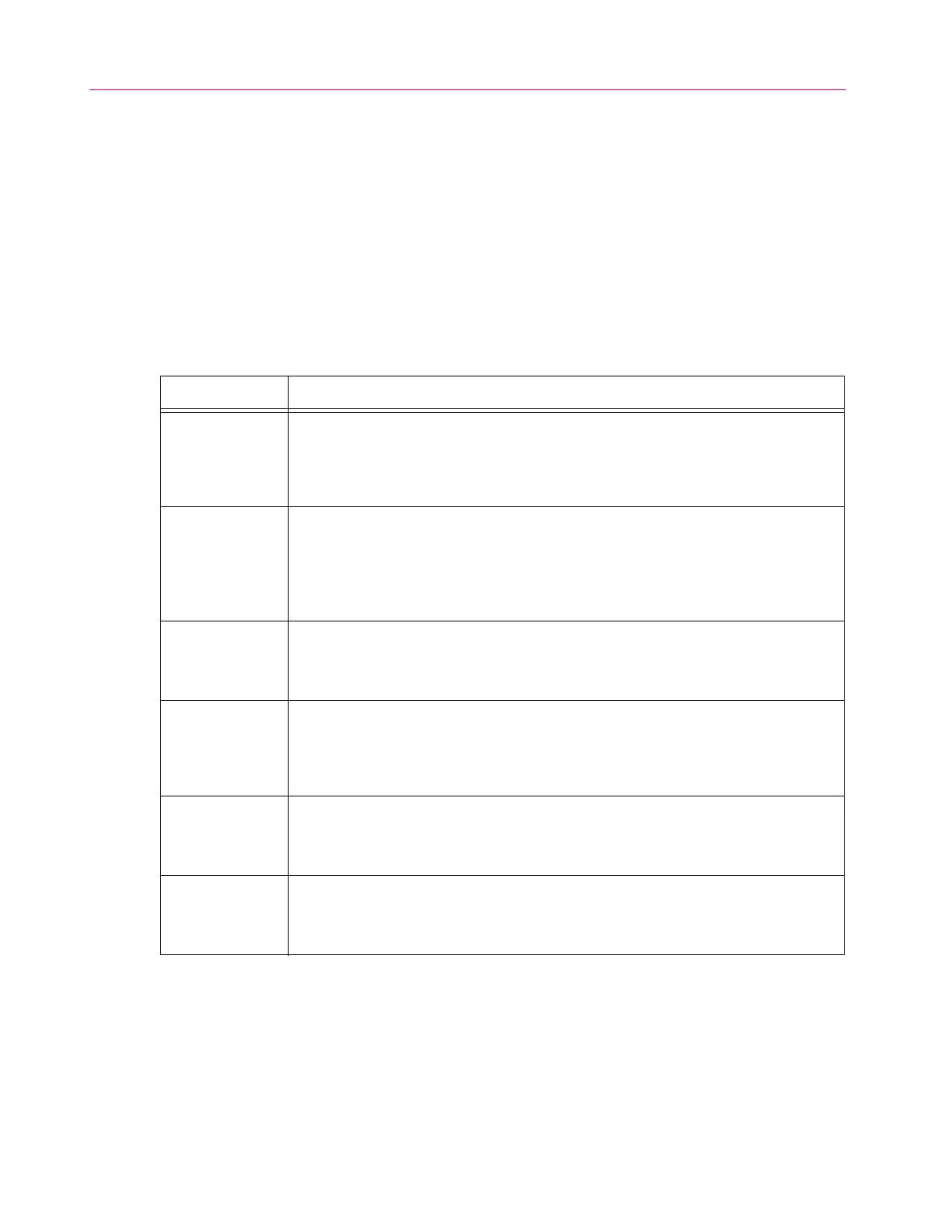

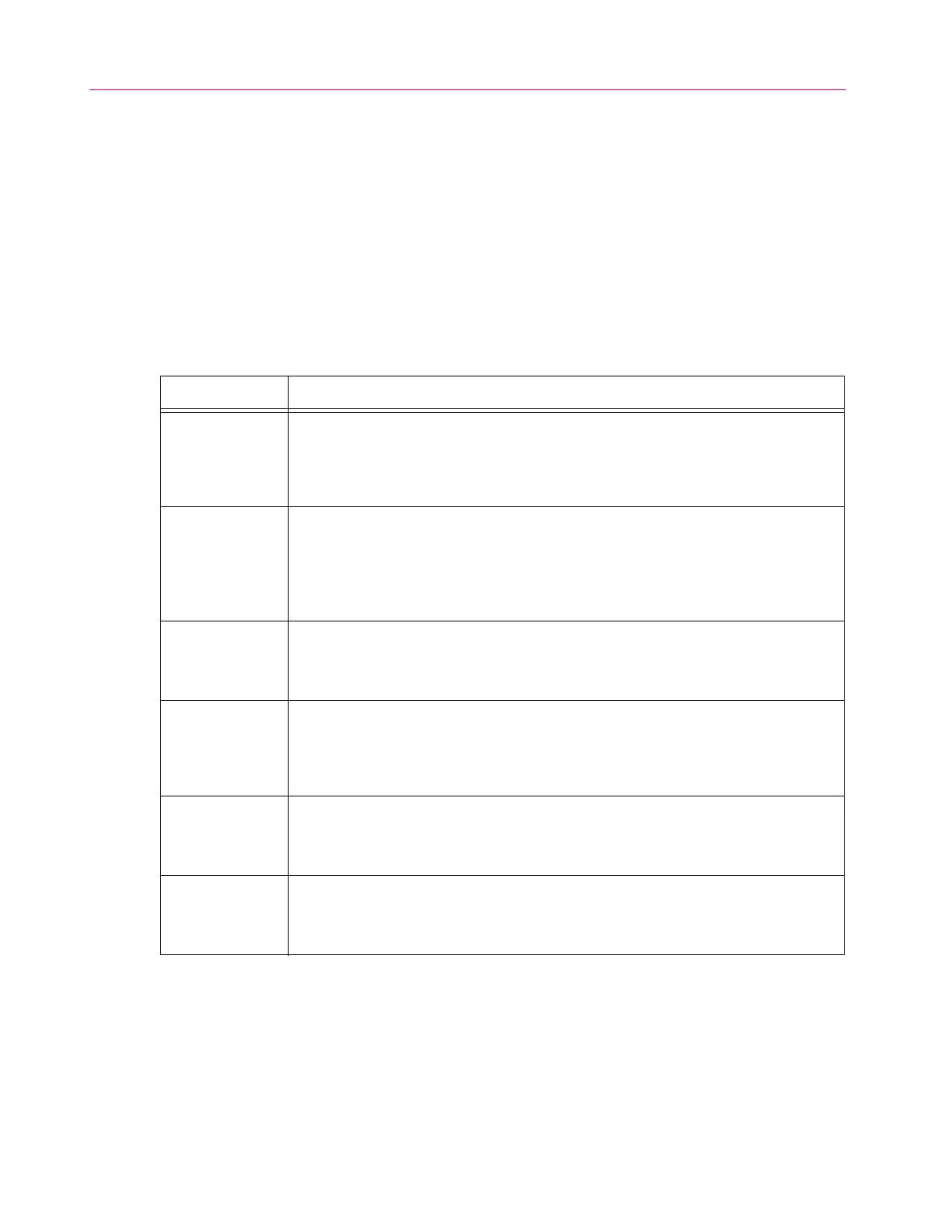

Table 4. Function of components on servo manifold.

Component Function

Servo valve: The servo valve controls the flow of oil to the hydraulic cylinder. The position of the servo

valve, which is determined by parameters entered into the controlling software by the

operator, defines how the hydraulic cylinder will operate. It will either block the flow of oil to

the hydraulic cylinder to hold the piston stationary, allow oil to enter the hydraulic cylinder to

extend the piston, or allow oil to return to the reservoir to retract the piston.

Oil filter: A high pressure 3-micron oil filter is mounted on the manifold to provide the necessary

filtration for the high performance hydraulic components in the system. Oil passes through

this filter directly after exiting the pump and before being routed to any other hydraulic

component. The filter is equipped with an indicator to show when the filter is dirty and

should be serviced. For maintenance of the oil filter, refer to maintenance information

provided in the System Operating Instructions (supplied separately).

System pressure

gauge:

A pressure gauge is located on the servo manifold so that system pressure can be monitored

as needed. This pressure gauge is visible through a cut out in the left side cover of the base.

System pressure is set at the factory and should not require further adjustment. Any

adjustments should only be made by an Instron service engineer.

Dump valve: When unloading the frame, the servo valve changes position to allow oil to return through the

system to the reservoir. Also, the dump valve can open to allow oil to return directly to the

reservoir, thus providing for a faster unload rate. The dump valve actually cycles to maintain

the error signal within prescribed limits. This can cause a pulsing sound from the frame

while it is unloading. This is considered normal and is not a cause for concern.

Idle pressure valve: The idle pressure valve controls the pressure of the HPS when it is operating under no load

conditions (i.e. when the frame is not being adjusted or performing a test). This valve is set

at the factory and should not require further adjustment. Any adjustments should only be

made by an Instron service engineer.

System relief valve: The system relief valve provides pressure relief for the system to prevent damage to system

components in the event that the pump builds too much pressure. This valve is set at the

factory and should not require further adjustment. Any adjustments should only be made by

an Instron service engineer.

Loading...

Loading...