26

NOTE:

• Motor and gear are maintenance-free. Only basical

checks can be done

• The driving unit can only be replaced completely.

9.0 Checks and repair work at motor, gear, servo and steering

9.1 Driving motor and gear

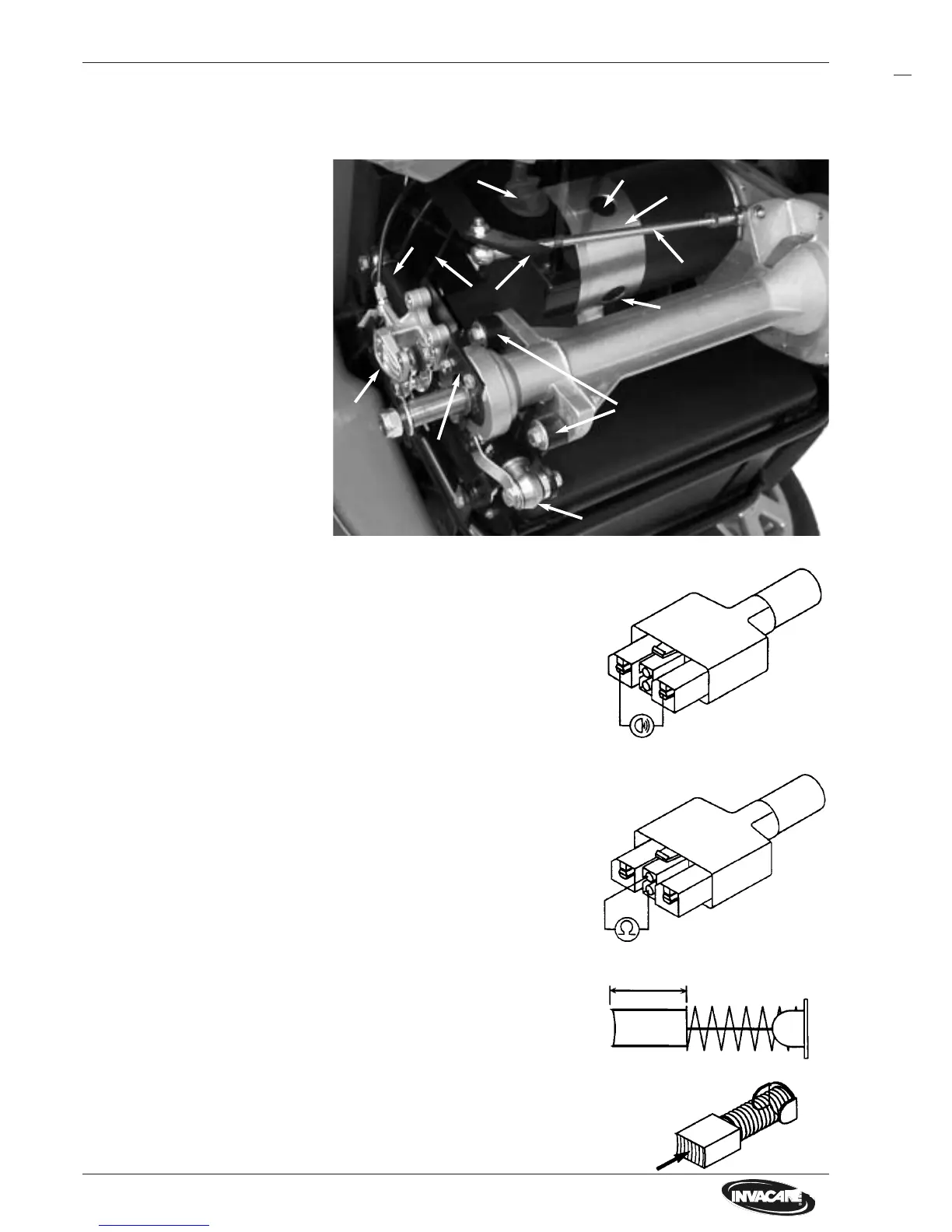

Driving motor

2

3

4

5

6

7

10, 11, 12,

13, 14, 15

8, 9

16

1 Chassis

2 Driving motor 450W

3 Stopper with carbon brush

4 Disengaging lever

5 Gear, compl.

6 Thread rod with

square hinge

7 Shock absorber

8 Mounting

9 Hexagon head screw.

M5x20

10 Gear rocker arm

11 Hexagon head screw

M8x35

12 Rubber support

13 Socket 12x1,8; 8x18

14 Disc 8,4

15 Nut M8

16 Brake caliper

3

1

7

• Motor vibrates, has operation sounds?

• Motor does not start?

• Elektric brake does not apply?

• Gear has operation sounds or blocks?

> Check or replace motor.

> Check or replace motor.

> Check or replace brake.

> Replace driving unit.

Check Action

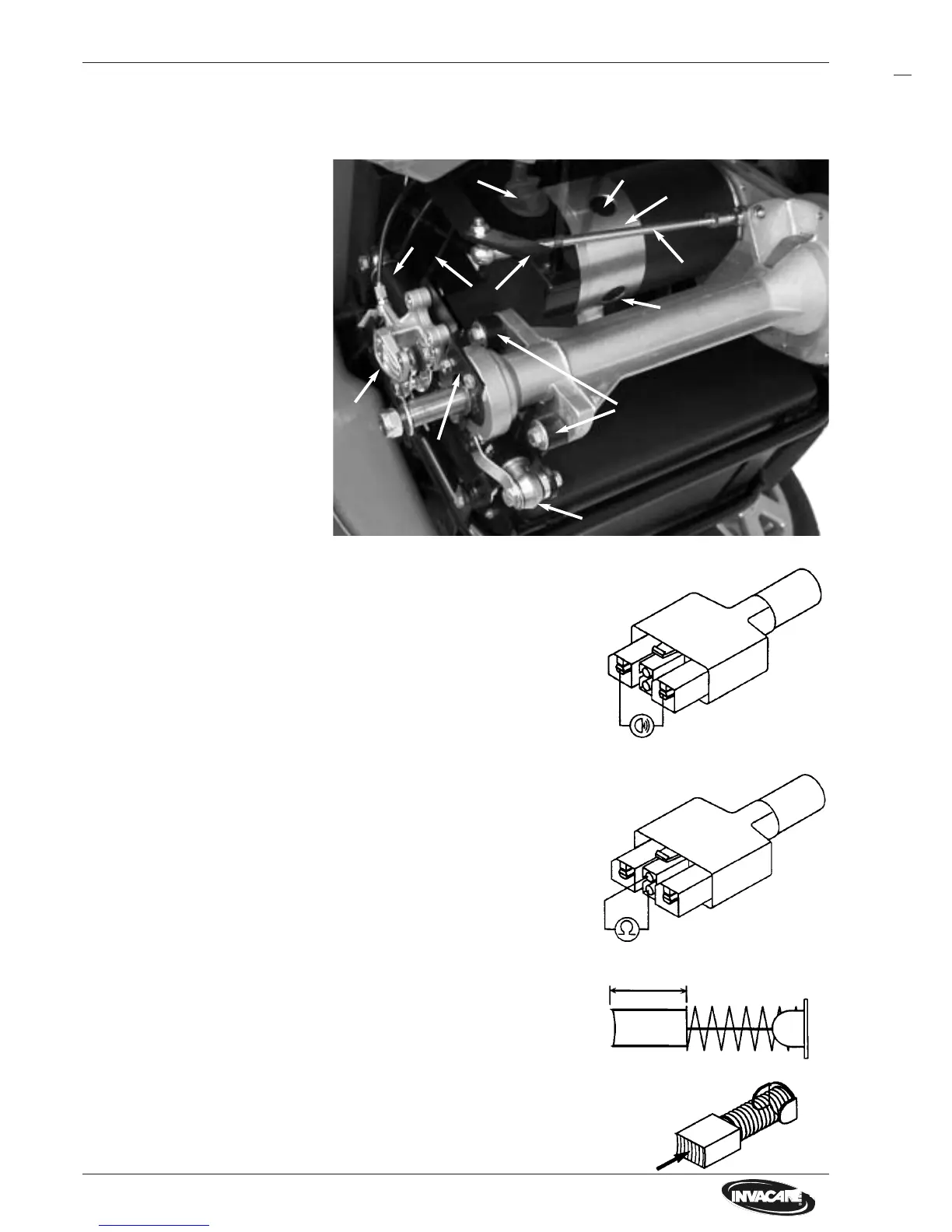

Check circuit of motor

• Bring seat system in service position and arrest.

• Take off both motor plugs from main module.

• Engage motor (driving mode).

• Check with multimeter (measuring range Ohm) as shown in diagram.

It must show circuit.

• Disengage motor (freewheel operation ) and repeat measurement.

The measured value should ascend to infinite when driving operation is

changed into freewheel operation.

Check electric brake

• Check with multimeter (measuring range Ohm) as shown in diagram.

The measured value should lie between 20 and 200 Ohm.

Check carbon brush

• Remove the four closure caps (3) and take out carbon brushes.

• Measure length of brushes. The original length lies at 13mm. The

abrasion limit is 11mm.

• Check working surface visually. The working surface must not show any

grooves.

Check circuit of motor

Check electric brake

Check carbon brush

min. 11 mm

Working surface

Length

Loading...

Loading...