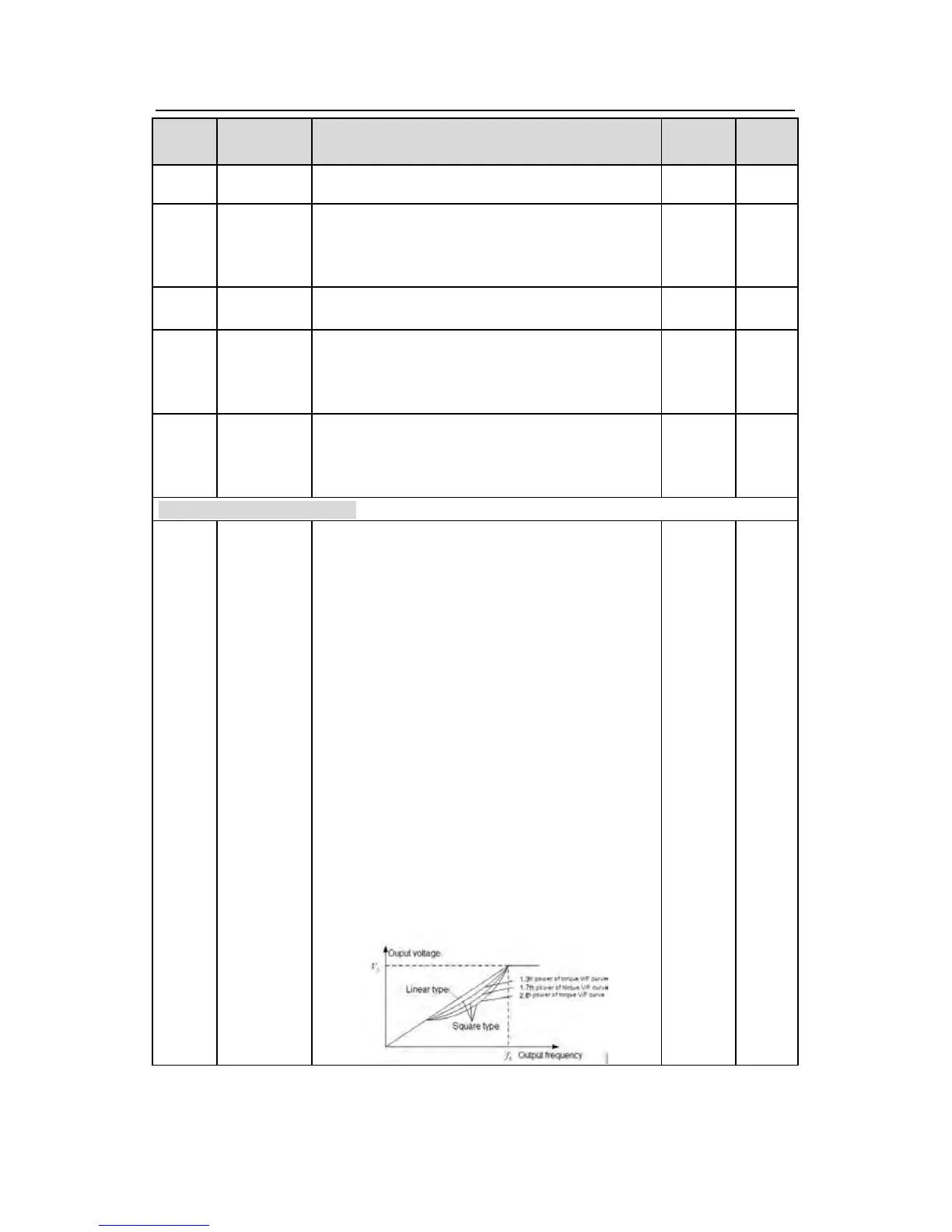

These function codes define the V/F curve of

Goodrive200A motor 1, and meet the need of

different loads.

0:Straight line V/F curve;applying to the constant

torque load

1:Multi-dots V/F curve

2:1.3

th

power low torque V/F curve

3:1.7

th

power low torque V/F curve

4:2.0

th

power low torque V/F curve

Curves 2~4 apply to the torque loads such as

fans and water pumps. Users can adjust

according to the features of the loads to achieve

a best energy-saving effect.

5:Customized V/F(V/F separation); in this mode,

V can be separated from f and f can be adjusted

through the frequency reference channel set by

P00.06 or the voltage reference channel set by

P04.27 to change the feature of the curve.

Note: V

b

in the below picture is the motor rated

voltage and f

b

is the motor rated frequency.

Loading...

Loading...