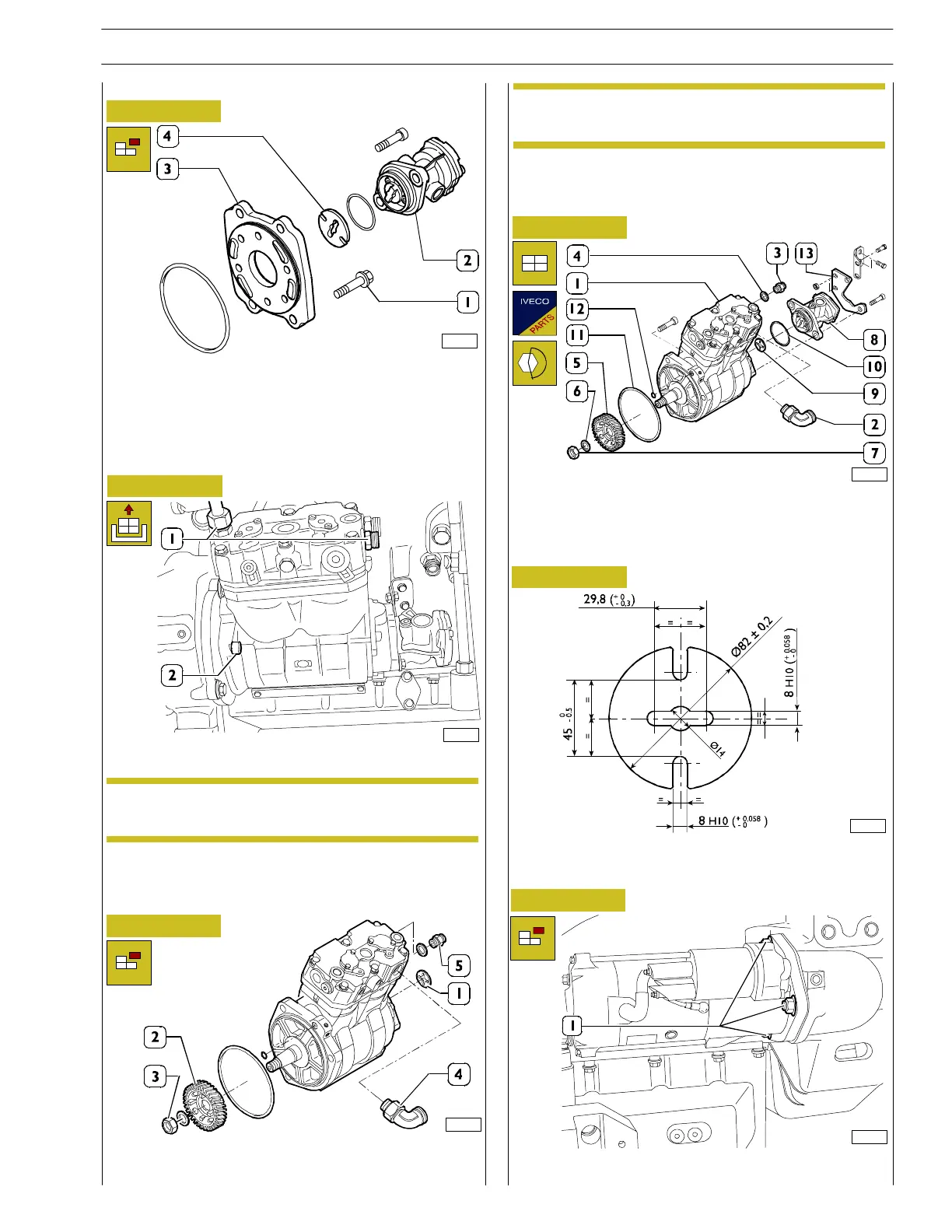

Figure 12

Figure 13

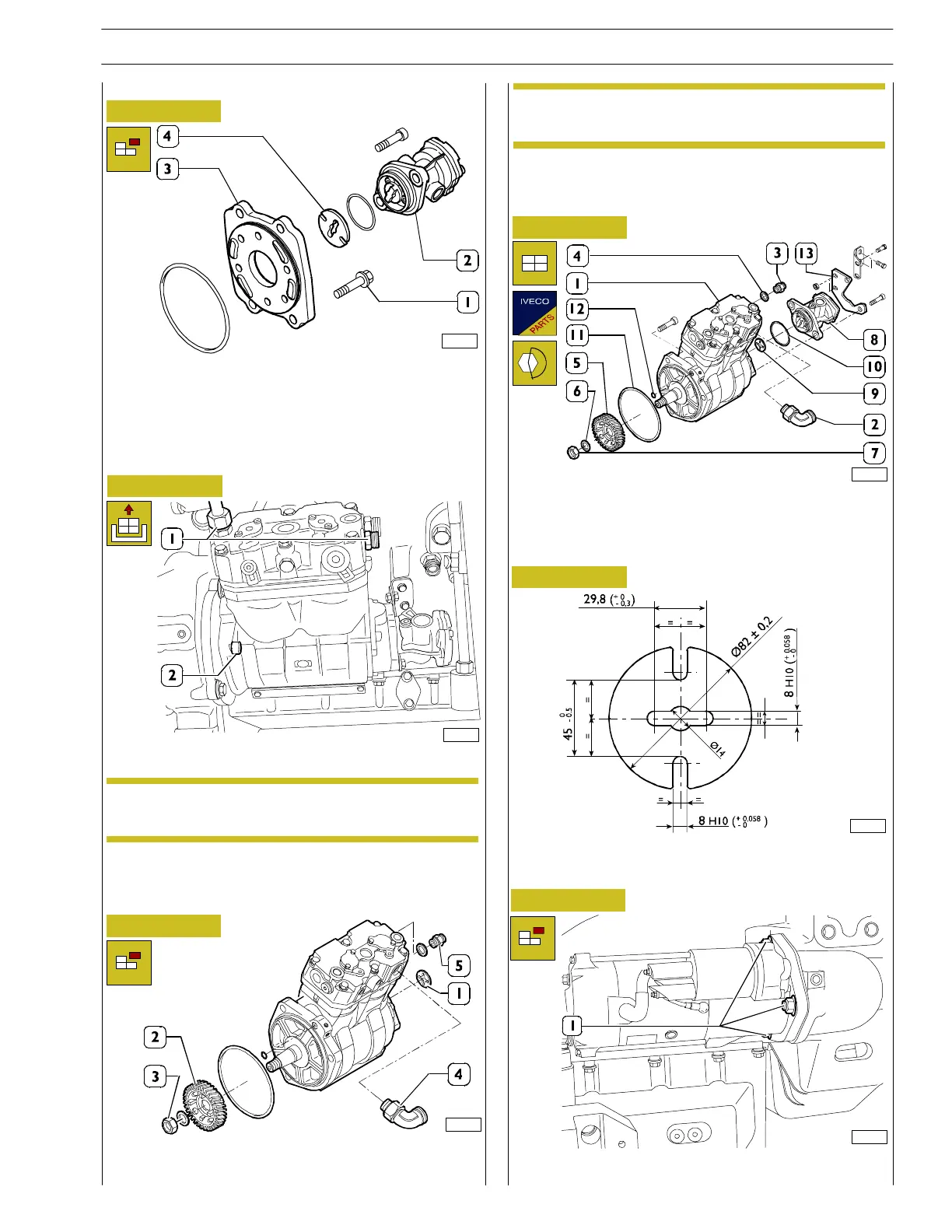

Figure 14

Figure 15

- Unscrew the three scre ws (1) fixi ng the supp or t to the

gearbox and remove the the low—pressure supply pump

(2).

- On the bench, go ahead and remove the support (3) and

separate the low—pressure supply pump (2); in addition,

remove the coupling drive (4).

103475

For G-DRIVE, GRIFFON and SPRINKLER applications

For DRAGON applications

- Disconnect the coolant connecting pipes (1).

89698

It is advisable to plug both the pipes and the ports on

the compressor that has to be shipped for overhaul.

- Unscrew t he fixin g screw s of brakets (13, Figure 15)

- Unscrew th e screws (2, Figure 13) fixing the compressor

on the spacer.

NOTE

- Take the compressor to the workbench and separate

the l ow-pressure pump (if not previously removed ).

Recover the universal joint (1), checking its state of

wear.

- After firmly secu rin g the compressor in a vice, remove

the gear (2) by unscrewing the nut (3) and using a specific

extractor. In addition, remove the fittings (4) and (5).

- Unsc rew the screw (13) t hat fixing the LPP (8) to air

compressor.

- Divide the LPP (8) from air compressor and recover

coupling drive (9) and O-ring (10).

For all applications

81969

NOTE

89697

- Check the state of wear of the coupling drive and its

coupling w ith th e low—pressure pump spindle.

Figure 16

83490

- Remove the starter motor by unscrewing the three nuts

(1).

82205

Figure 17

SECTION 3 - INDUSTRIAL APPLICATION

15

VECTOR 8 ENGINES

Print P2D32V001E Base - April 2006

Loading...

Loading...