Zodiac strongly recommends that you call a qualified service technician to perform any repairs on the filter/pump

system. To locate a qualified technician, check your local yellow pages or visit www.zodiac.com and click on “Product

Support.”

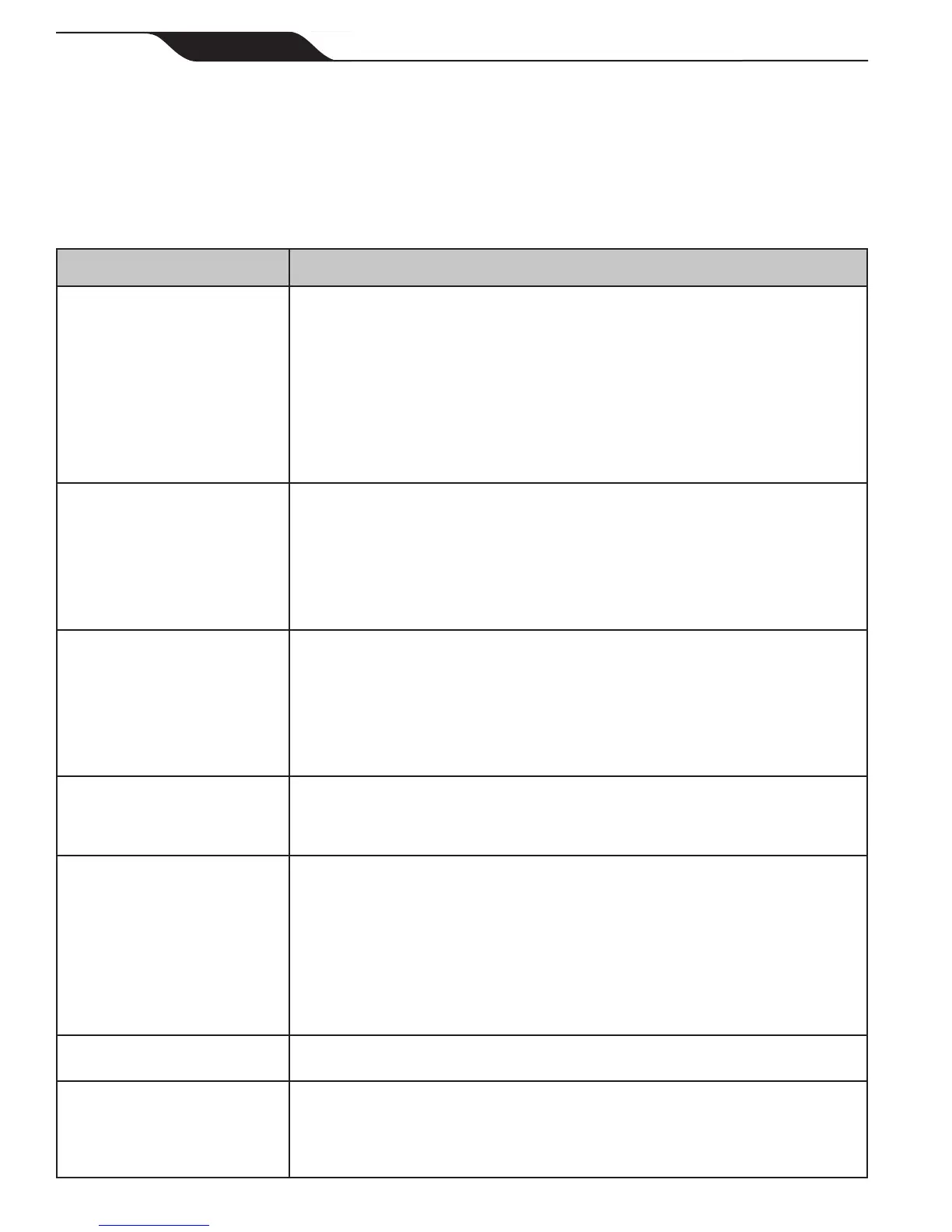

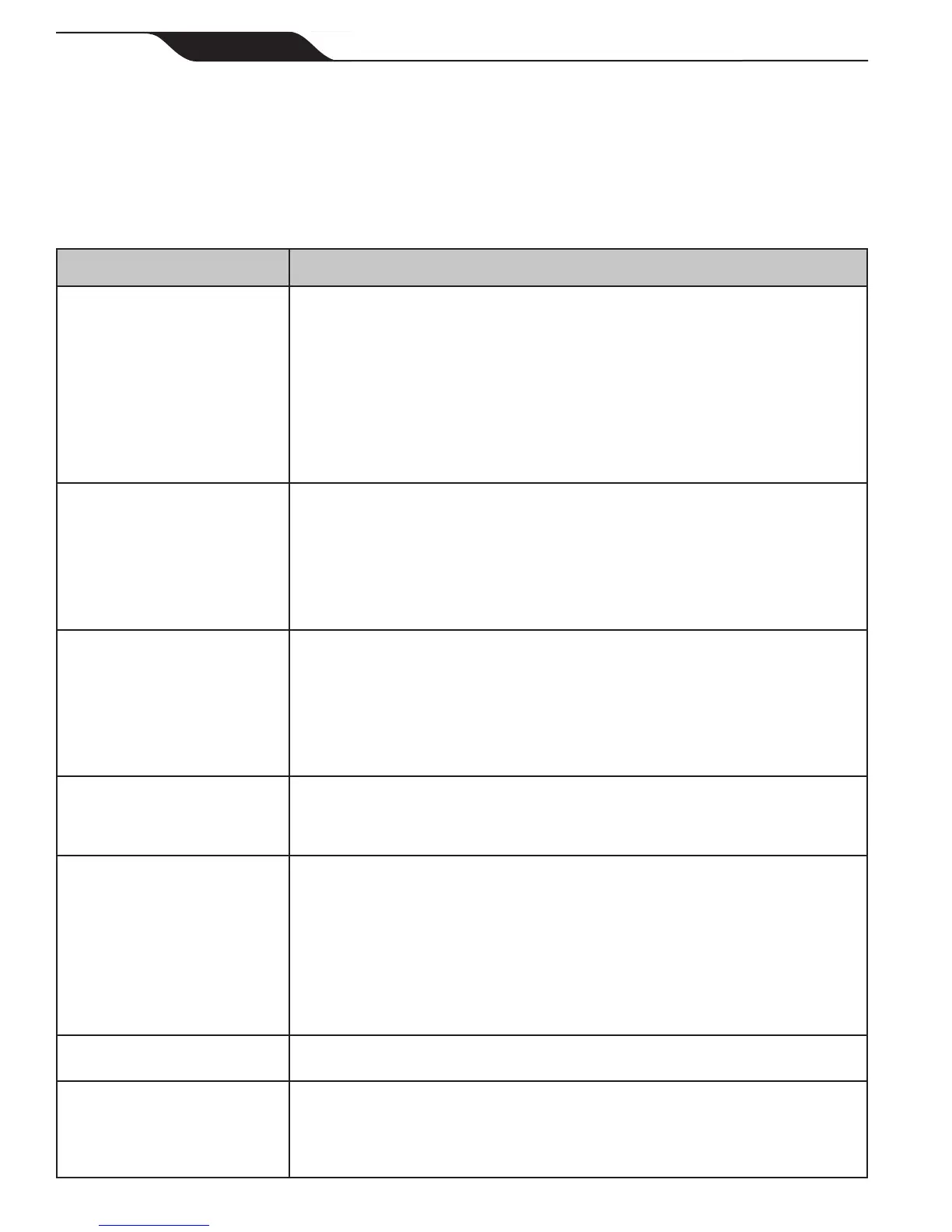

Thecleaning/circulatingsystemis

notoperatingcorrectly.

Verifythatskimmerbaskets,pumpbasketandotherscreensareclean.Cleanas

necessary.

Checkfilterandcleanasnecessary.

Checkvalvepositions.Adjustasnecessary.

NOTEMultiplepiecesofequipmentoperatingatonetime(forexample,waterfalls,spa

jets,andsurfacereturns)willaffecttheproperoperationofthecleaningsystem.

Checkthecleaningsystemmanualtoensurethatthesystemisadjustedaccordingtothe

manufacturer'srecommendations.

Bubblesarepresentinthepump

basket.

Airisinthesystem.Checkthepoolorspawaterleveltoensurethatitisattheproperlevel

andairisnotbeingdrawnintothesuctionpiping.Ifthewaterisatthenormallevel,turnoff

thepump.Turnthelid'slockingringcounter-clockwiseuntil'START'alignswiththeports.

RemovethelidandcheckfordebrisaroundthelidsealseatORimproperinstallationof

thelidseal,aseitherconditionwillallowairtoleakintothesystem.Cleanthelidsealand

replaceitonthelid.Replacethelidonthepumphousing.Align'START'withtheportsand

turnthelockingringclockwiseuntil'LOCKED'alignswiththeports.Hand-tightenthelidto

makeanair-tightseal.Do not use any tools to tighten the lid. Turnthepumpbackon.

Airleaksarestillpresent. Checkthesuctionsidepipingunion.Whilethepumpisrunning,trytotightentheunion.If

thisdoesnotstoptheairleak,turnoffthepump.Loosenbothunionsandslidethepump

outoftheway.Remove,clean,andre-installbothuniono-rings.

Repositionthepumpnexttothepipingandsecuretheunionnutstothepump.Withclean

uniono-rings,hand-tighteningoftheunionsshouldcreateaseal.Iftheunionsstilldonot

seal,gentlytightenwithalargepairoftongue-and-groovepliers.

Do not over-tighten.

Thereisnoairinthesystem,but

thepressureisstilllow.

Itispossiblethatdebrisiscaughtinthepumpimpeller.Thepumpimpellermovesthe

water,andthevanesintheimpellercanbecomeblockedwithdebris.SeeSection

6.2, Service Technician Maintenance, 6.2.1, Blocked Impeller, inthismanualformore

information.

Thereisnodebrisblockingthe

impellerandthepressureisstill

low.

Thepumpimpelleranddiffuserareshowingsignsofnormalwear.Haveaqualifiedservice

technicianchecktheimpelleranddiffuserandreplaceasnecessary.

Ifthepumpispartofarelativelynewinstallation,itcouldbeanelectricalproblem.Contact

aqualifiedservicetechnician.Havethetechniciancheckforlooseelectricalconnections

andcheckthevoltageatthepumpmotorwhileitisinoperation.Thevoltagemustbewithin

10%ofthemotor'sdataplaterating.Ifthevoltageisnotwithin10%,contactaqualified

electricianand/orthelocalpowerserviceprovider.

Pumpsealisleakingair.Haveaqualifiedservicetechnicianreplacetheseal.

Thepumpisleakingwaterbetween

themotorandpumpbody.

Thisiscausedbyadamagedorfailedmechanicalseal.Replacetheseal.SeeSection 6.2,

Service Technician Maintenance, 6.2.3, Mechanical Seal Replacement,inthismanual.

Thepumpgetshotandshutsoff

periodically.

Makesurethatthereisadequateroomaroundthemotortocirculateairandkeepthe

motorcool.Haveaqualifiedelectriciancheckforlooseconnectionsandcheckthevoltage

atthepumpmotorwhileitisinoperation.Thevoltagemustbewithin10%ofthemotor's

dataplaterating.Ifthevoltageisnotwithin10%,contactaqualifiedelectricianand/orthe

localpowerserviceprovider.

Page 16

Jandy

®

FloPro™ Variable-Speed Pump Series VS-FHP

|

Installation and Operation Manual

ENGLISH

Loading...

Loading...