25

10.5 mm

B

A

4. Needle to Cutter Cam Timing

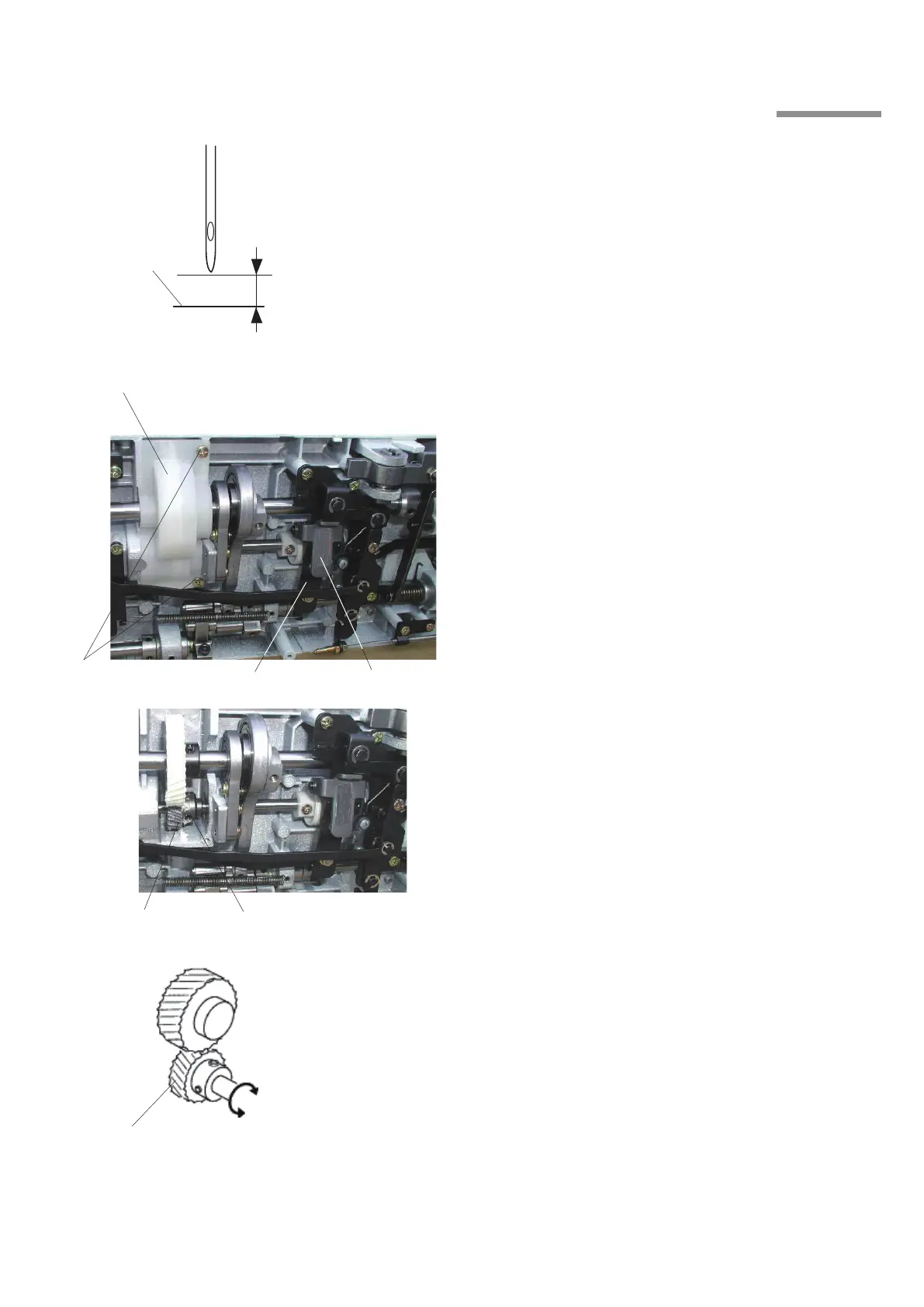

Remove the base.

Remove the setscrews

q

and gear cover

w

.

Lower the needle bar to the lowest position.

Turn the handwheel toward you to raise the needle

bar while pushing up the link body

e

.

Continue to turn the handwheel until the thread

drawing arm

r

starts to move to the right.

The needle point should be 10.5 mm above the upper

surface of the needle plate

t

when the thread

drawing arm starts to move.

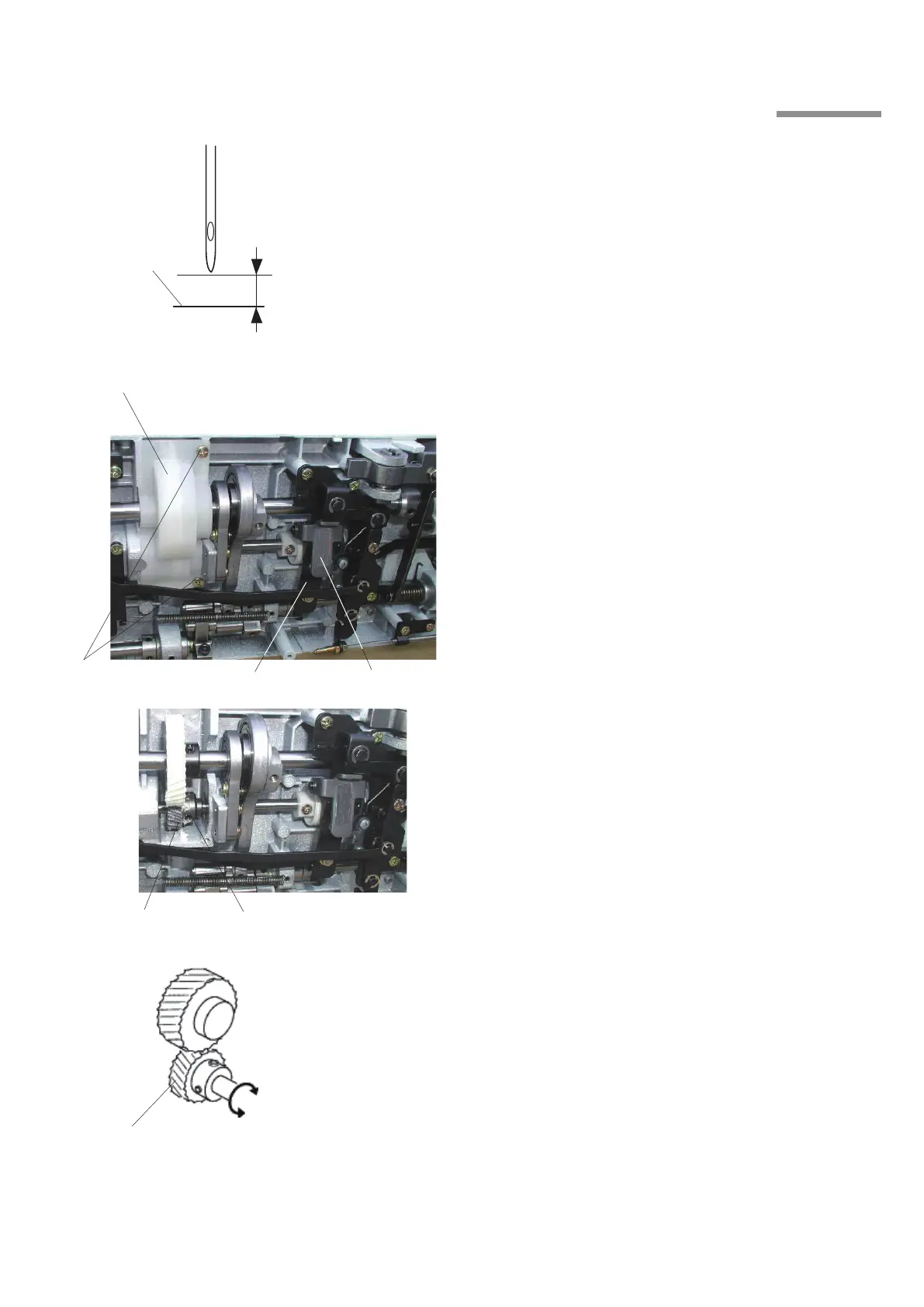

Loosen the setscrews

y

and turn the hook shaft

gear

u

to adjust the timing.

• If the needle point is too high, turn the hook shaft gear

in the direction

A

.

• If the needle point is too low, turn the hook shaft gear in

the direction

B

.

NOTES:

Hold the hook so that it will not rotate when turning the

hook shaft gear.

Check the needle to hook timing and adjust it if

necessary.

Tighten the setscrews

y

firmly. Attach the gear

cover

w

and secure it with the setscrews

q

.

Attach the base.

z

x

c

v

b

n

t

w

e

r

q

u

y

u

Loading...

Loading...