6

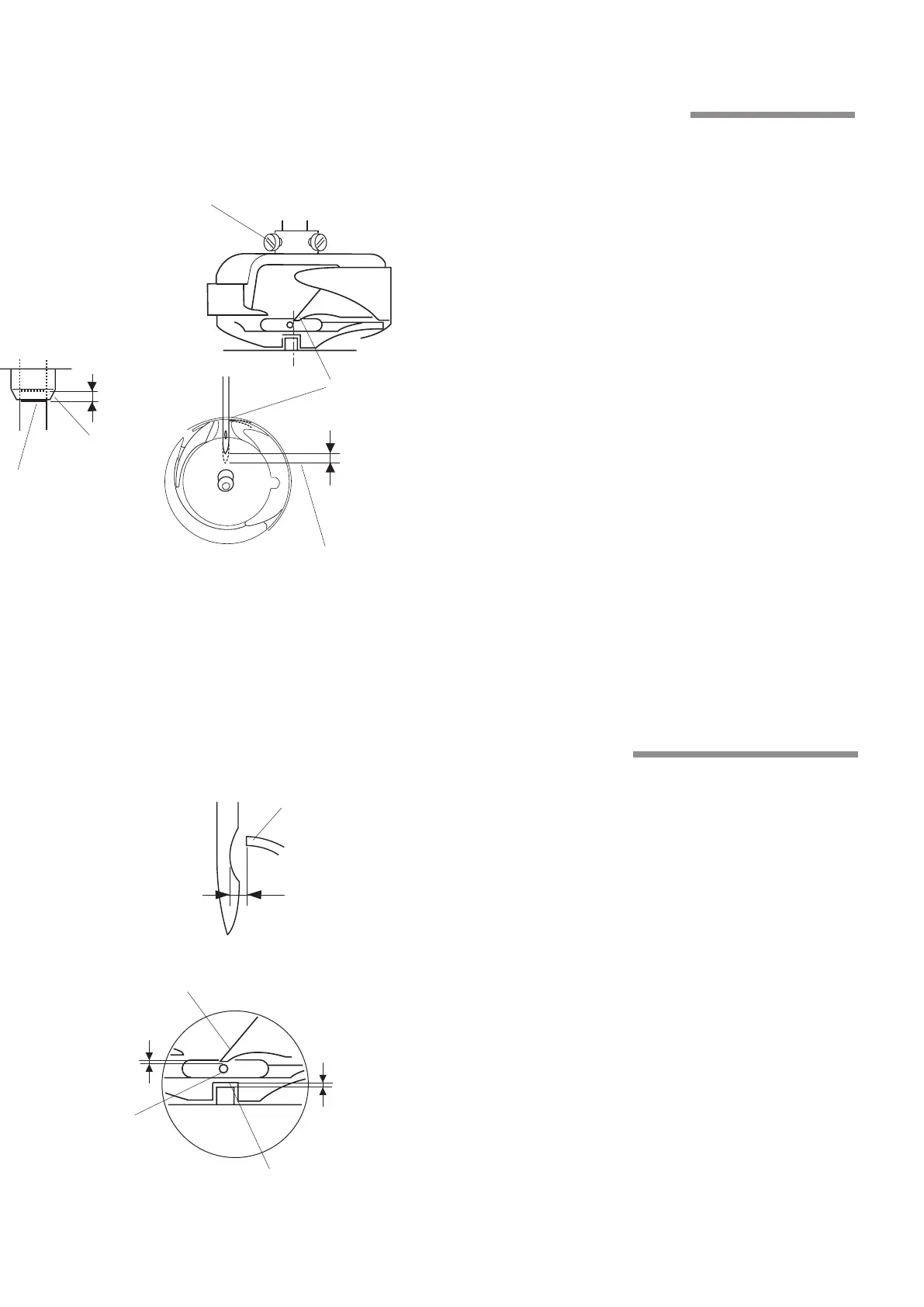

0 to 0.1mm

1.8 to 2.2 mm

1.8 to 2.2 mm

7. Needle to Hook Timing

Remove the needle plate.

Loosen the 3 setscrews

q

. Pull out the hook race

very slightly (less than 0.5 mm).

Raise the needle bar from the lowest position until the

lower hairline

w

of the needle bar matches the edge

of the needle bar bushing

e

.

NOTE:

The needle bar rises 2 mm from the lowest position.

Rotate the hook to match the hook point

r

with the

right side of the needle.

Tighten the setscrews

q

slightly and proceed with the

adjustment of the clearance between the needle and

hook point.

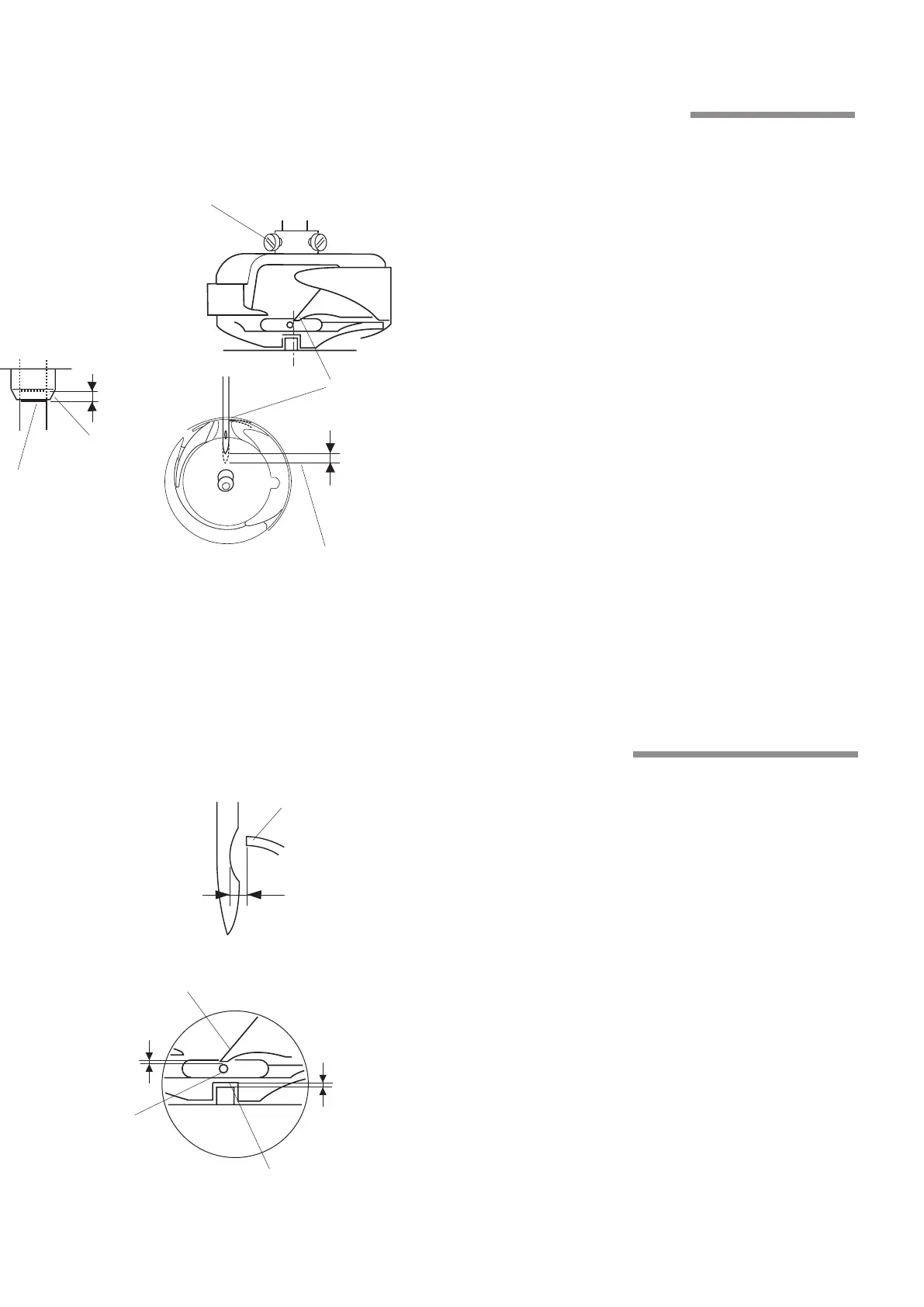

8. Clearance Between Needle

and Hook Point

The clearance between the needle and hook point should

be 0 to 0.1 mm.

Turn the handwheel to bring the hook point

q

behind

the needle

w

.

Knock on the hook race rim lightly to make a slight

clearance between the needle and hook point.

NOTE:

Do not knock on the hook body.

Tighten the setscrews firmly and check the needle to

hook timing and the thread path

e

(0.4 to 0.8 mm).

Attach the needle plate.

z

x

x

z

c

c

v

v

b

q

w

e

r

Lowest position

q

w

e

q

0 to 0.1mm

0.4 to 0.8mm

Loading...

Loading...