P/N 960-000180R_Rev. 1 {EDP #233427} © 2016, JAPAN CASH MACHINE CO., LTD.

Section 6 DBV® Series DBV-400 Banknote Validator Calibration and Testing

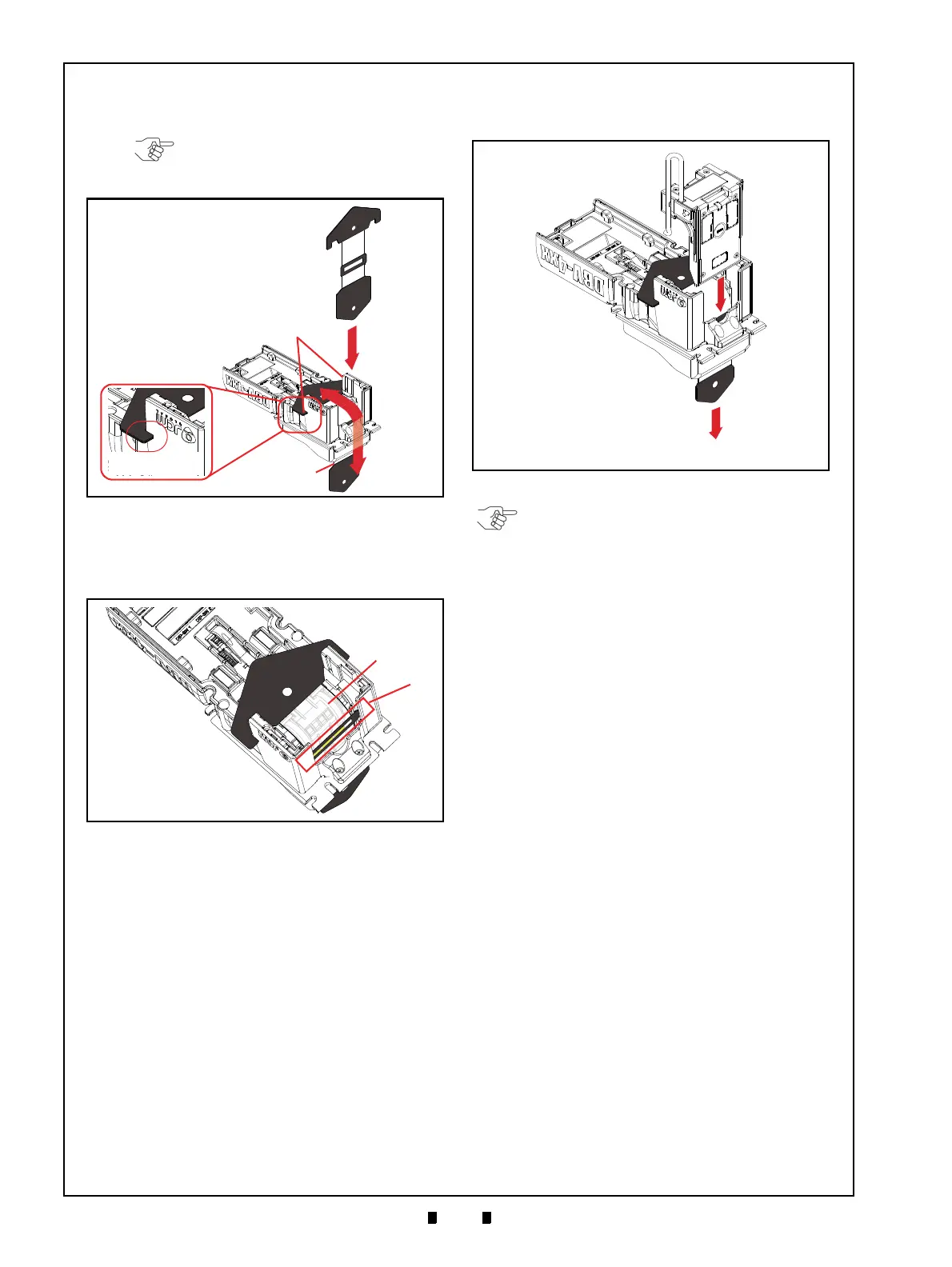

5. Hook the KS-095A Reference Paper Tabs into

both sides of the Cut-out Space on the DBV-400

Unit (Figure 6-27 c).

6. Place the KS-095A Reference Paper

(Figure 6-28 b) in the center of the Transport Path

to ensure the Inside Sensors are covered by the

Reference Paper as shown in Figure 6-28a.

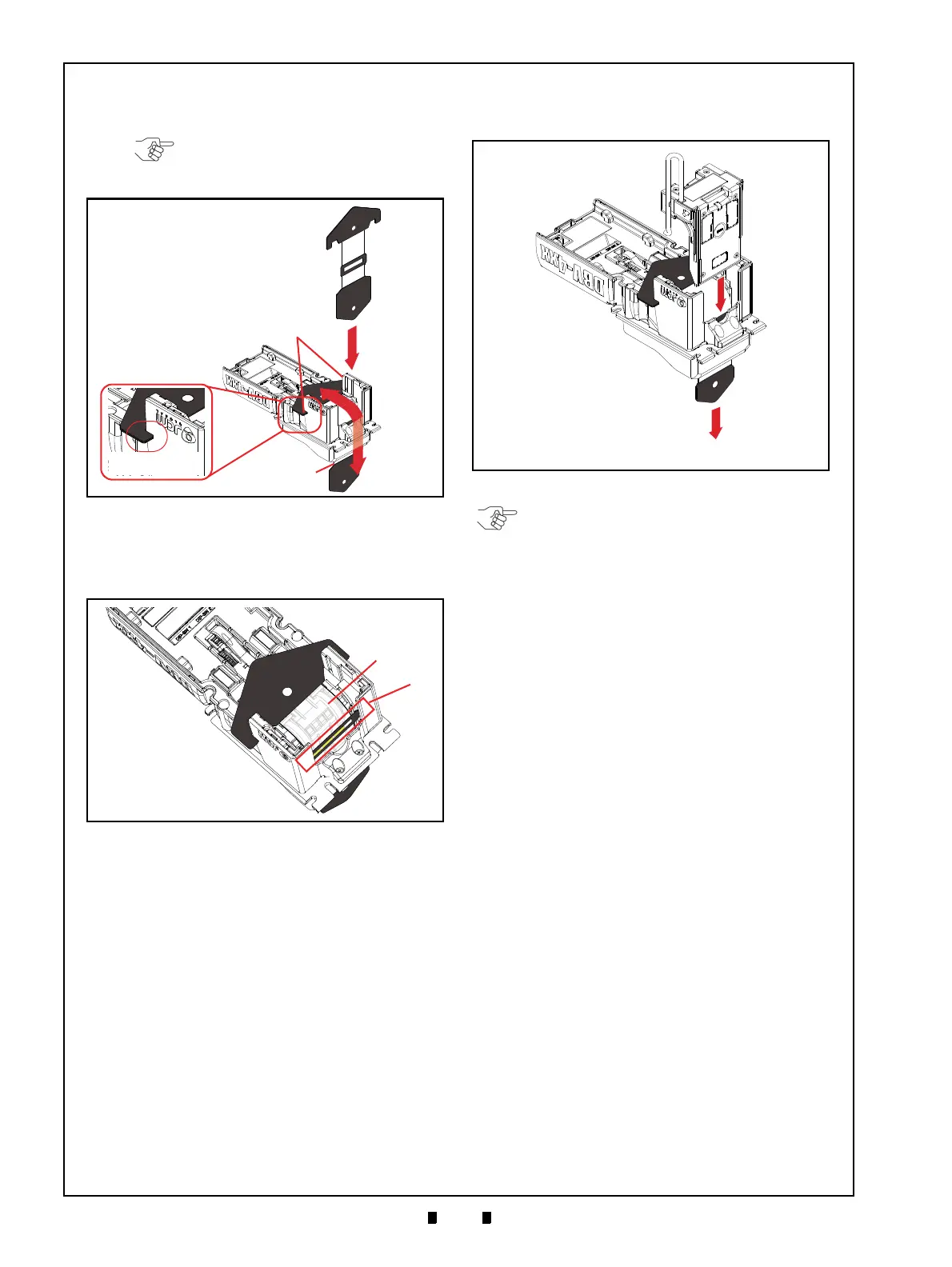

7. Firmly set the Validation Guide (Figure 6-29 a)

while adjusting the KS-095A Reference Paper

(Figure 6-29 b) placement location until the

Guide “clicks” into place, and ensure that it is

tightly locked.

8. Pull the KS-095A Reference Paper (Figure 6-29

b) just slightly in the direction indicated by the

red arrow A until the Reference Paper is taut.

NOTE: Make sure that the Reference

Paper Tabs are firmly hooked into the

Cut-out Space.

Figure 6-27 Placing KS-095A Reference

Figure 6-27 Placing KS-095A Reference Paper 4

Figure 6-28 Placing KS-095A Reference Paper

Figure 6-28 Placing KS-095A Reference Paper 5

Figure 6-29 Placing KS-095A Reference

Figure 6-29 Placing KS-095A Reference Paper 6

NOTE: Make sure that the Guide Chip A

(Figure 6-26 a) and Guide Chip B (Figure

6-26 b) are set back in the DBV-400 Unit

after calibration is complete.

Loading...

Loading...