Page 73 of 97

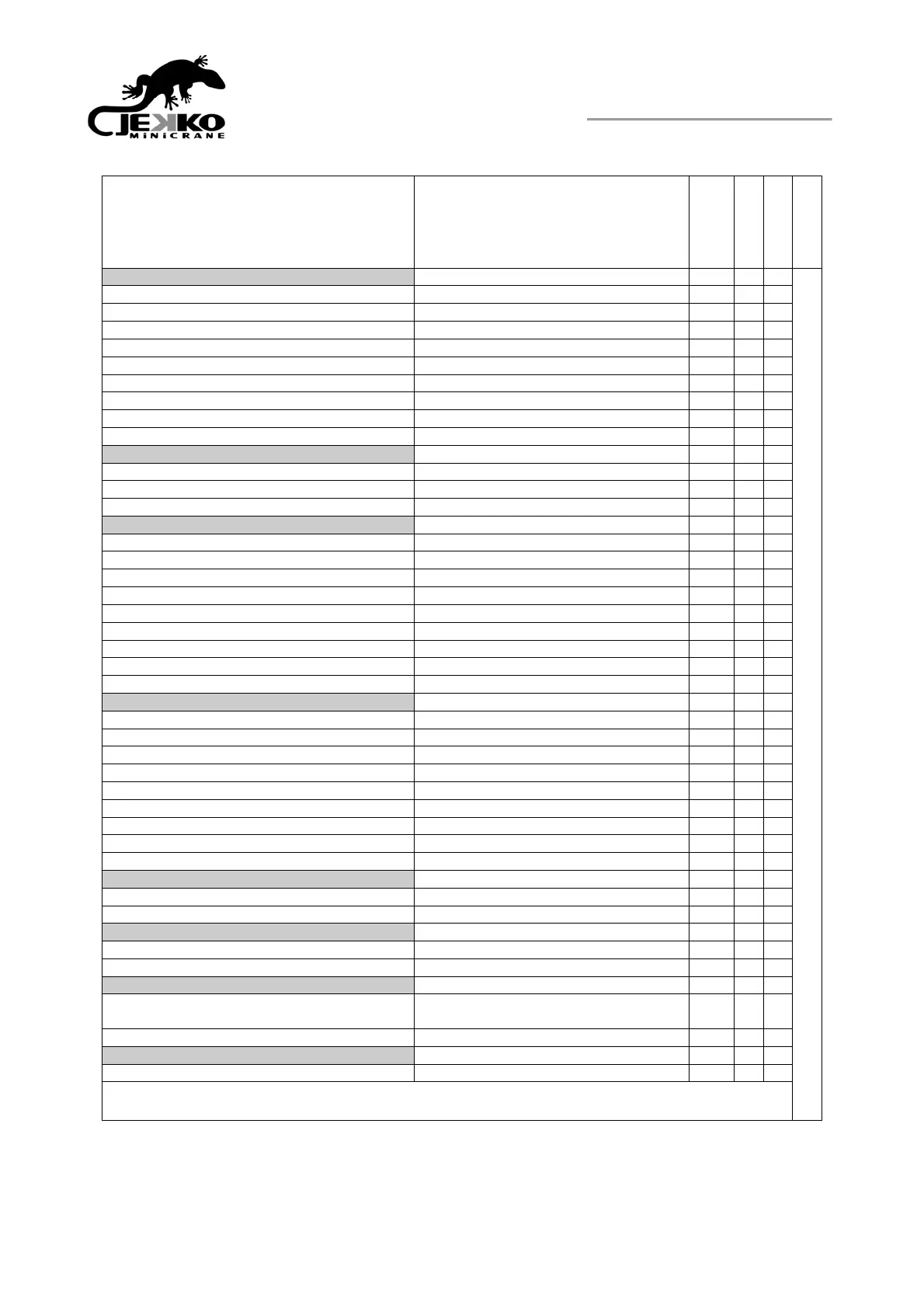

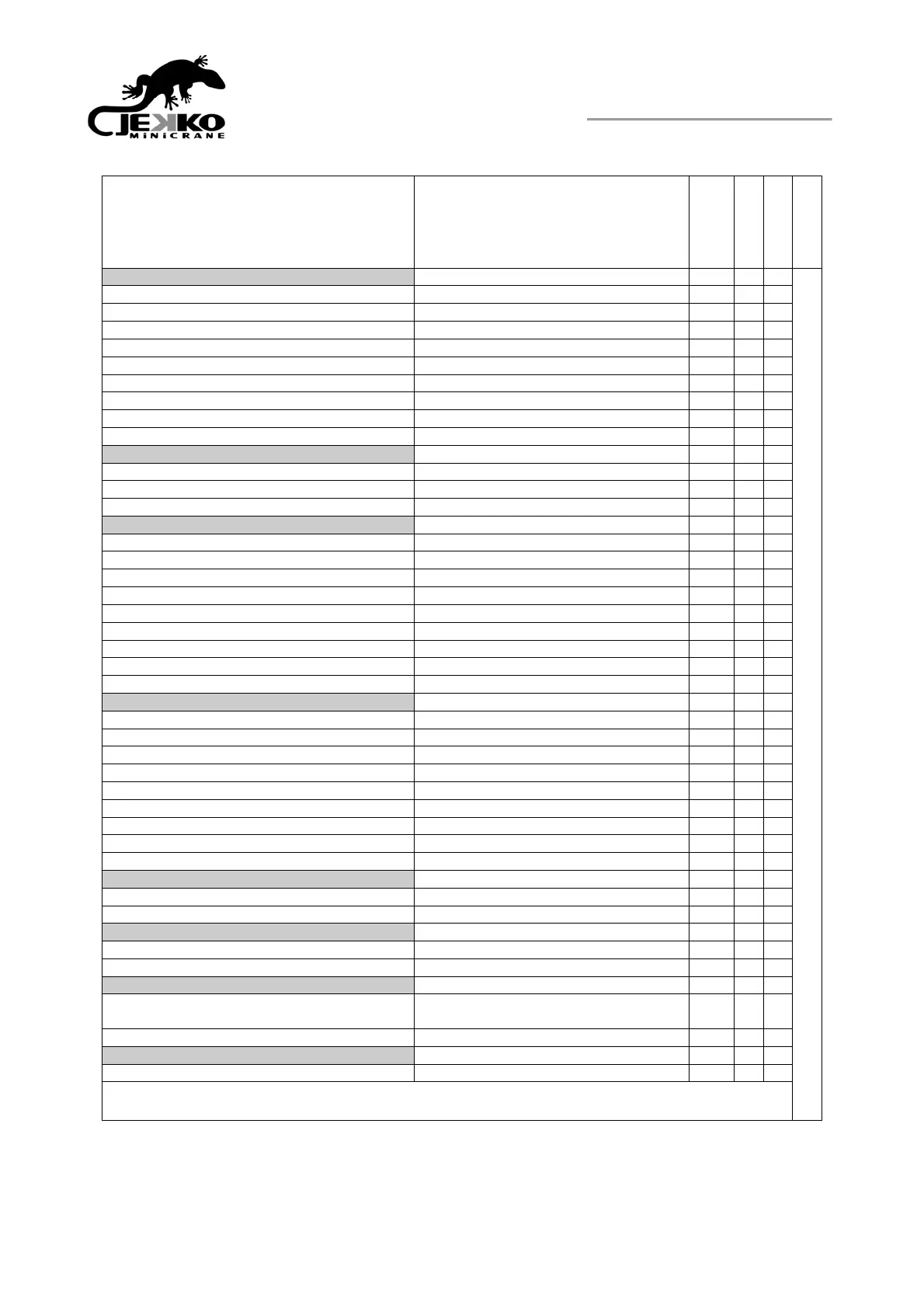

9 – STANDARD OPERATOR

MAINTENANCE

______________________________________________________________________________________________

COMPONENT PART TYPE OF CHECK

WEEKLY

500 ore

1000 ore

YEARLY

1. FRAME & STRUCTURE

COMPLETE CHECK OF THE MACHINE INCLUDED LOADING TESTS

•

Main frame

cricks and wear

X X

•

Crane pillar and extension

cricks and wear and greasing

X X

•

Outriggers cricks and wear and greasing

X X

•

Boom extensions chains cricks, wear, greasing and tightening

X X

•

Pin cricks, wear, greasing and tightening

X X

•

Track state of repair and wear

X X

•

Trucks Fixing Bolts cricks, wear and tightening

X X

•

Crane Fixing Bolts cricks, wear and tightening

X X

•

Frame Fixing Bolts cricks, wear and tightening

X X

2. LIFTING SYSTEM

•

Lifting hook cricks and wear

X X

•

Winch rope cricks and wear

X X

•

Lifting chains Lubrication

X

3. HYDRAULIC SYSTEM

•

Pump oil leakage, noise

X X

•

Oil tank oil level, oil condition

X X

•

Hydraulic oil changing

X

•

Filter changing

X

•

Cylinders and valves oil leakage

X

•

Outriggers valve bank oil leakage

X

•

Trucks and crane valve bank oil leakage

X

•

Flexible pipes oil leakage and wear

X X

•

Hydraulic pressure check

X

4. ELECTRICAL PARTS

•

All panel oxidation

X X

•

Power line state of repair and wear

X

•

Battery charge state and functioning

X X

•

Batteries electrolyte level

X X

•

Electrical engine state and functioning

X

•

Pressare detector functioning

X

•

Winch extensimeter functioning

X X

•

Angle sensor functioning

X X

•

Proximity functioning

X X

5. SAFETY DEVICES

•

Emergency Push Button functioning

X X

•

Signals on the switchboard functioning

X X

6. ACCESSORIES

•

Winch Greasing, functioning

X X

•

Power pack 380V functioning oil leakage

X X

7. WARNING PLATES

•

"CE" mark, identification

late of

the crane and of the accessories

presence and visibility

X X

•

Labels presence and visibility

X X

8. DIESEL ENGINE

•

Carter oil* level

X

* For more detail see the relative engine use and maintenance manual.

ATTENTION FIRST OIL MOTOR CHANGE MUST DO AFTER FIRST 50 WORKING HOURS

Loading...

Loading...