22

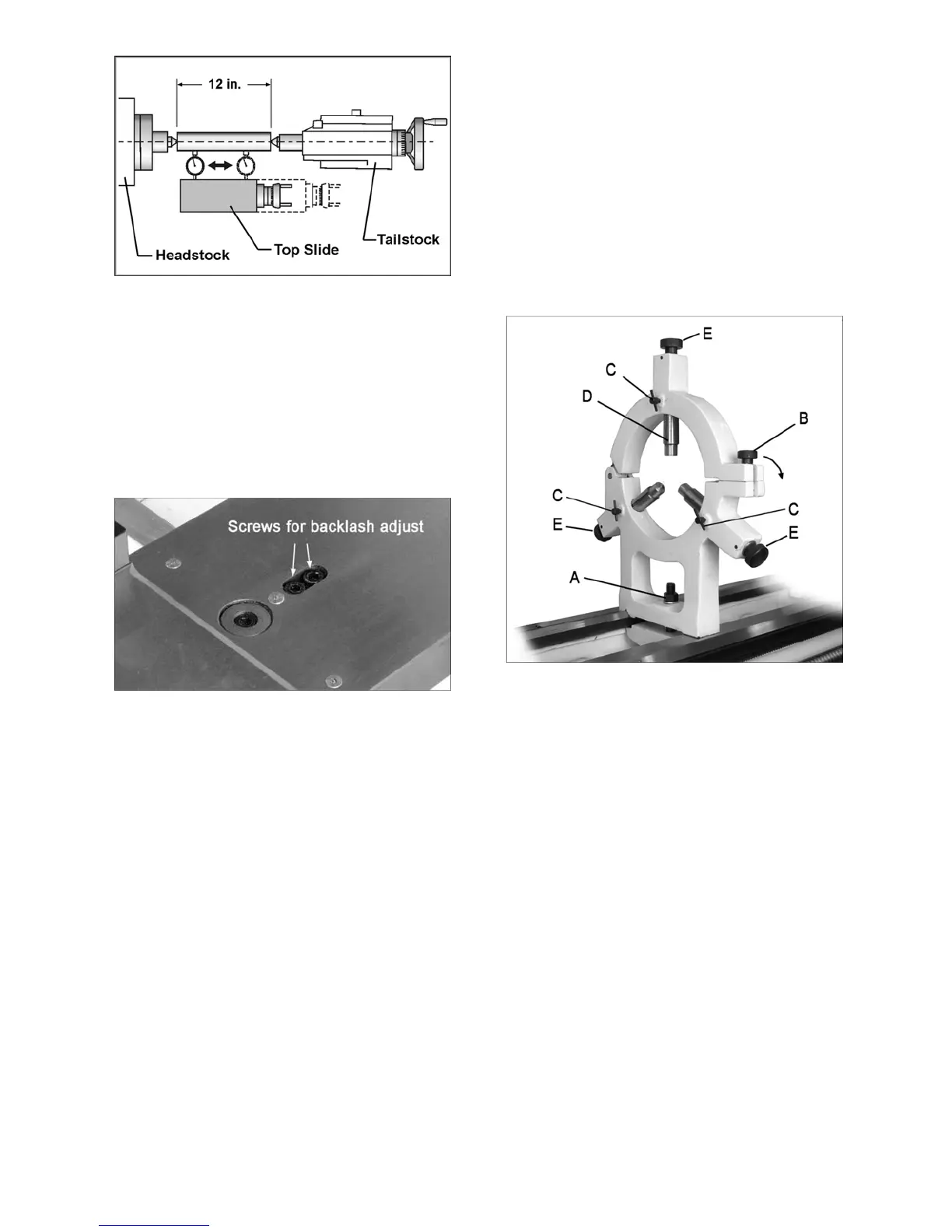

Figure 35 – Tailstock/Headstock alignment

13.7 Cross slide nut adjustment

The cross slide moves via a lead screw which

drives a nut. This can be adjusted if backlash

develops. Backlash is identified by turning the

cross slide handwheel left and right – if there is a

delay before any cross slide movement, the nut

needs adjusting.

Tighten or loosen the two screws shown in Figure

36 until backlash is adjusted out.

Figure 36 – Cross slide nut adjustment

13.8 Shear pin replacement

The lead screw and feed shaft are equipped with

shear pins, which are designed to break in order to

protect the drive system against overload. A

broken shear pin must be replaced.

Knock out the broken pin; line up the holes and

insert new pin.

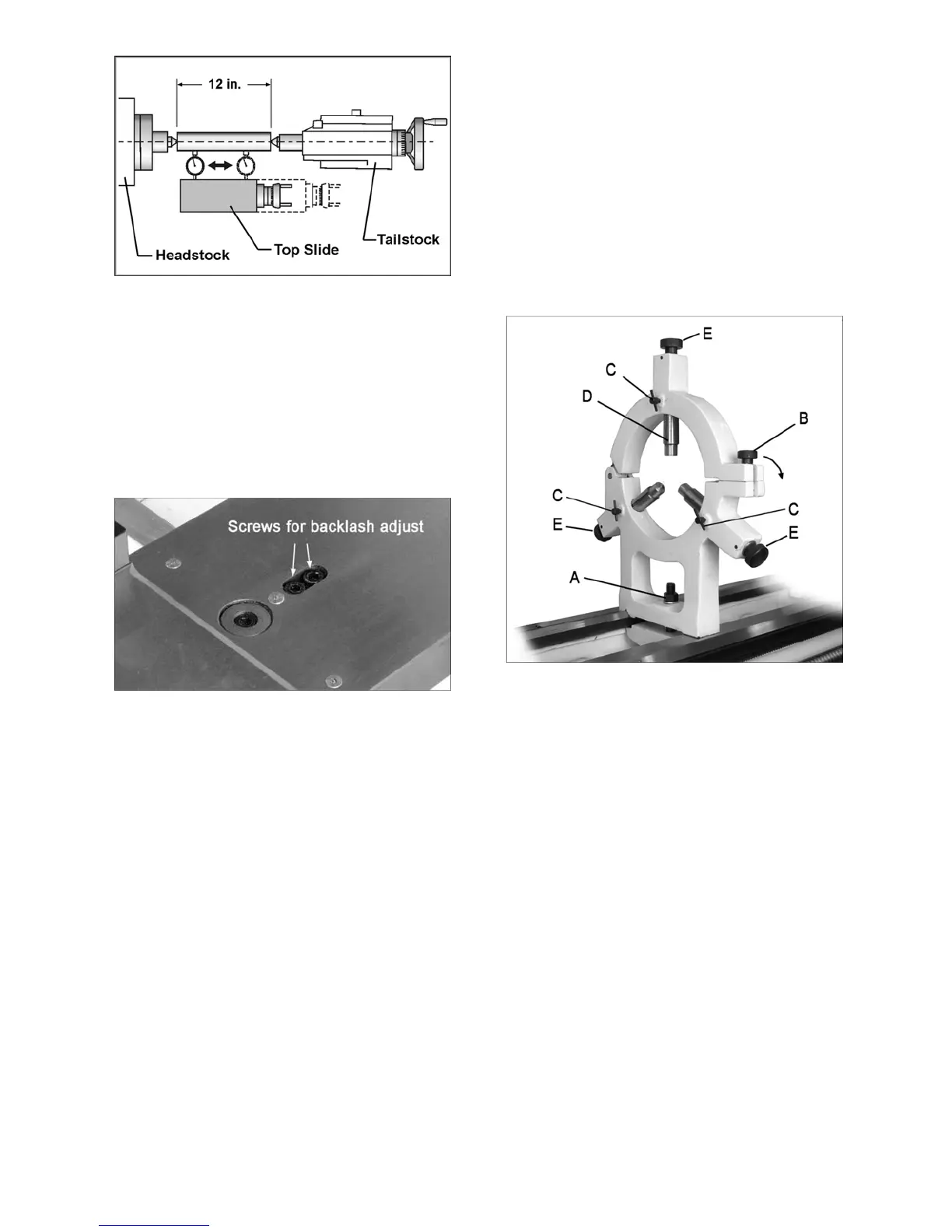

13.9 Steady rest adjustment

Always lubricate the fingers with grease before

using the steady rest. The point at which the

fingers contact the workpiece require continuous

lubrication to prevent premature wear.

To set the steady rest (see Figure 37):

1. Loosen hex nut (A) to slide steady rest along

the ways.

2. Loosen knurled handle (B) until it can be

pivoted out of the slot.

3. Loosen three lock knobs (C), and back off the

fingers (D) using knurled handles (E).

4. Pivot the collar on its hinge and position

steady rest around workpiece.

5. Firmly tighten hex nut (A).

6. Set the fingers snugly to work piece and

secure by tightening locking knobs. Fingers

should be snug but not overly tight.

Figure 37 – Steady rest adjustment

13.10 Follow rest adjustment

The follow rest mounts to the saddle with two

socket head cap bolts. The follow rest should be

mounted so that locking knobs point away from

chuck.

The sliding fingers are set similar to those on the

steady rest – free of play, but not binding.

Always lubricate the fingers sufficiently with grease

before operating.

Loading...

Loading...