14

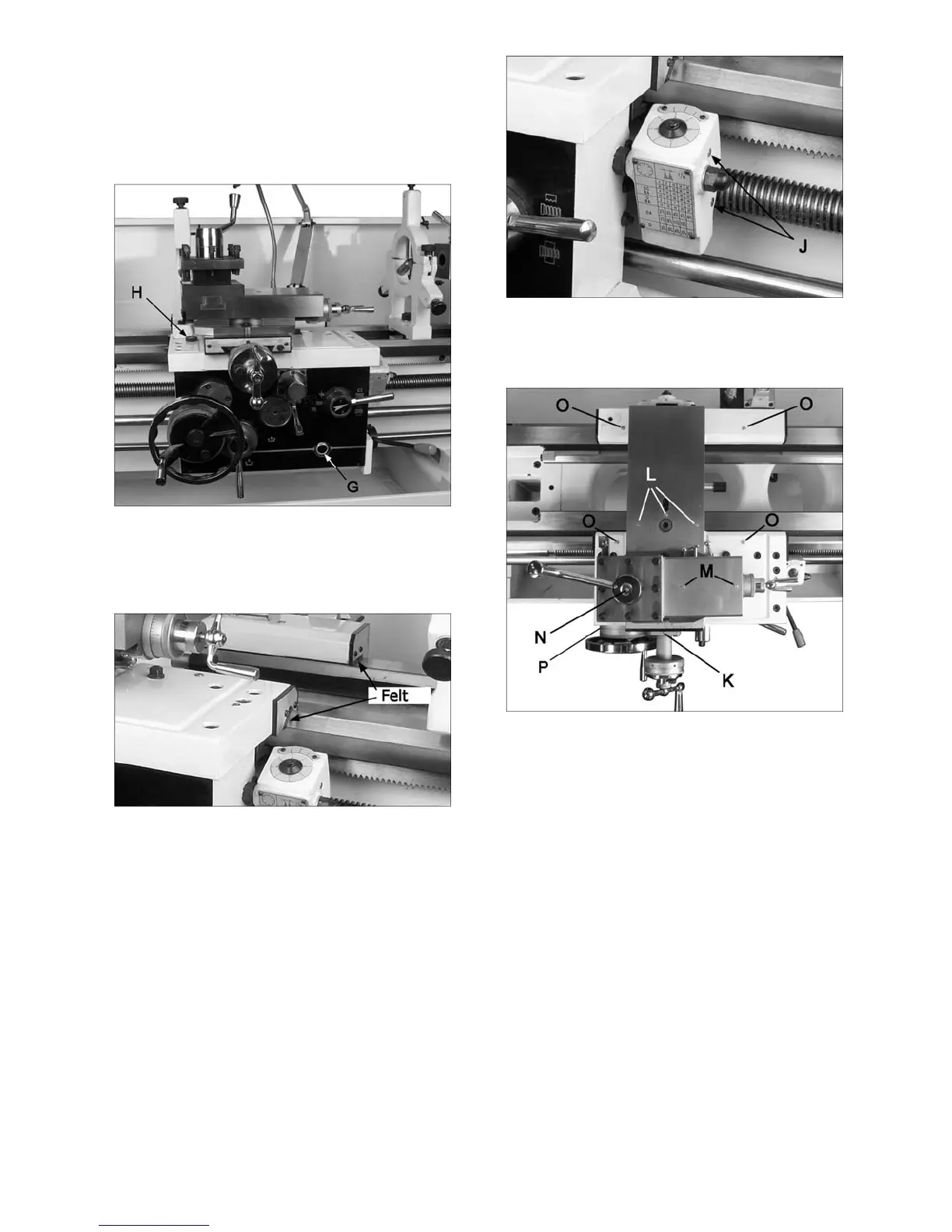

4. Apron – Oil must be between indicator marks

in the oil sight glass (G, Figure 11). Top off

with SAE 20W oil. Unscrew oil plug (H, Figure

11) to fill. To drain, remove drain plug on the

underside of apron. Drain oil completely and

refill after the first three months of operation.

Then, change oil in the apron annually.

Figure 11 – Lubrication points

5. Saddle – The anti-dust felt on both ends of the

saddle (Figure 12) should be cleaned weekly

with kerosene. If the felt becomes damaged,

replace it.

Figure 12– Anti-dust felt

6. V-Belts – Regularly check and adjust the

tightness of the v-belts to prolong their service

life. See section 13.5, Belt adjustment and

replacement.

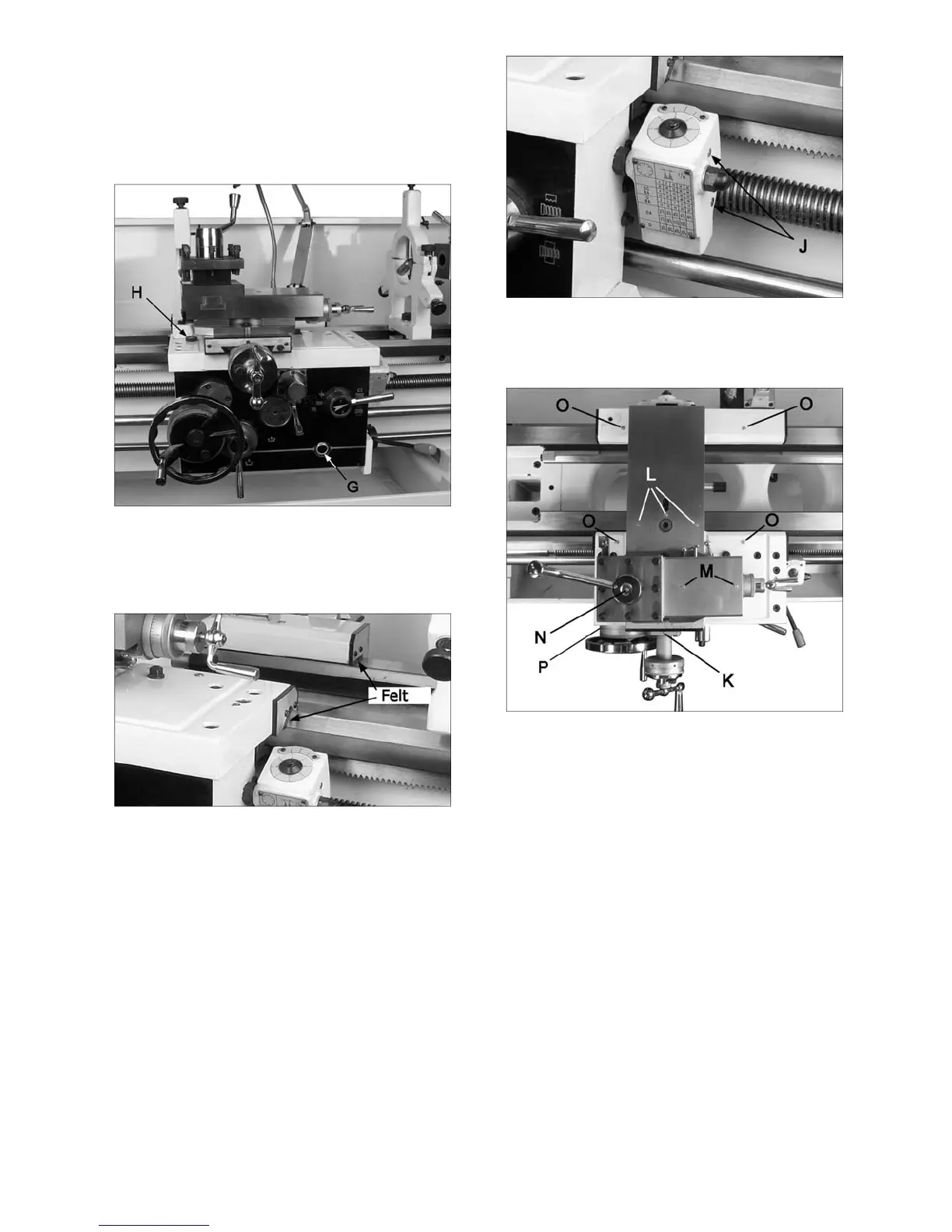

9.1 Ball oiler locations

All ball oilers must be lubricated with SAE-20W oil

(Mobil DTE

®

Oil Heavy Medium), as follows. Refer

to Figures 13 and 14.

7. Threading Dial – Daily lubricate two ball oilers

(J, Figure 13).

Figure 13

8. Cross Slide – Daily lubricate one ball oiler on

the handwheel housing (K, Figure 14) and

three ball oilers on the platform (L, Figure 14).

Figure 14 – Ball Oilers

9. Compound Rest – Daily lubricate two ball

oilers (M, Figure 14) on top of compound rest.

10. Tool Post – Regularly clean dirt and coolant

around the tool post to maintain its re-

positioning accuracy. Daily lubricate one ball

oiler on top the clamping hub (N, Figure 14).

11. Saddle – Daily lubricate four ball oilers (O,

Figure 14) and one ball oiler on the handwheel

shaft (P, Figure 14).

12. Leadscrew and Feed Rod – Lubricate two

ball oilers (Figure 15) once or twice per shift.

Loading...

Loading...