29

7.7- Belt tension adjustment and replacement

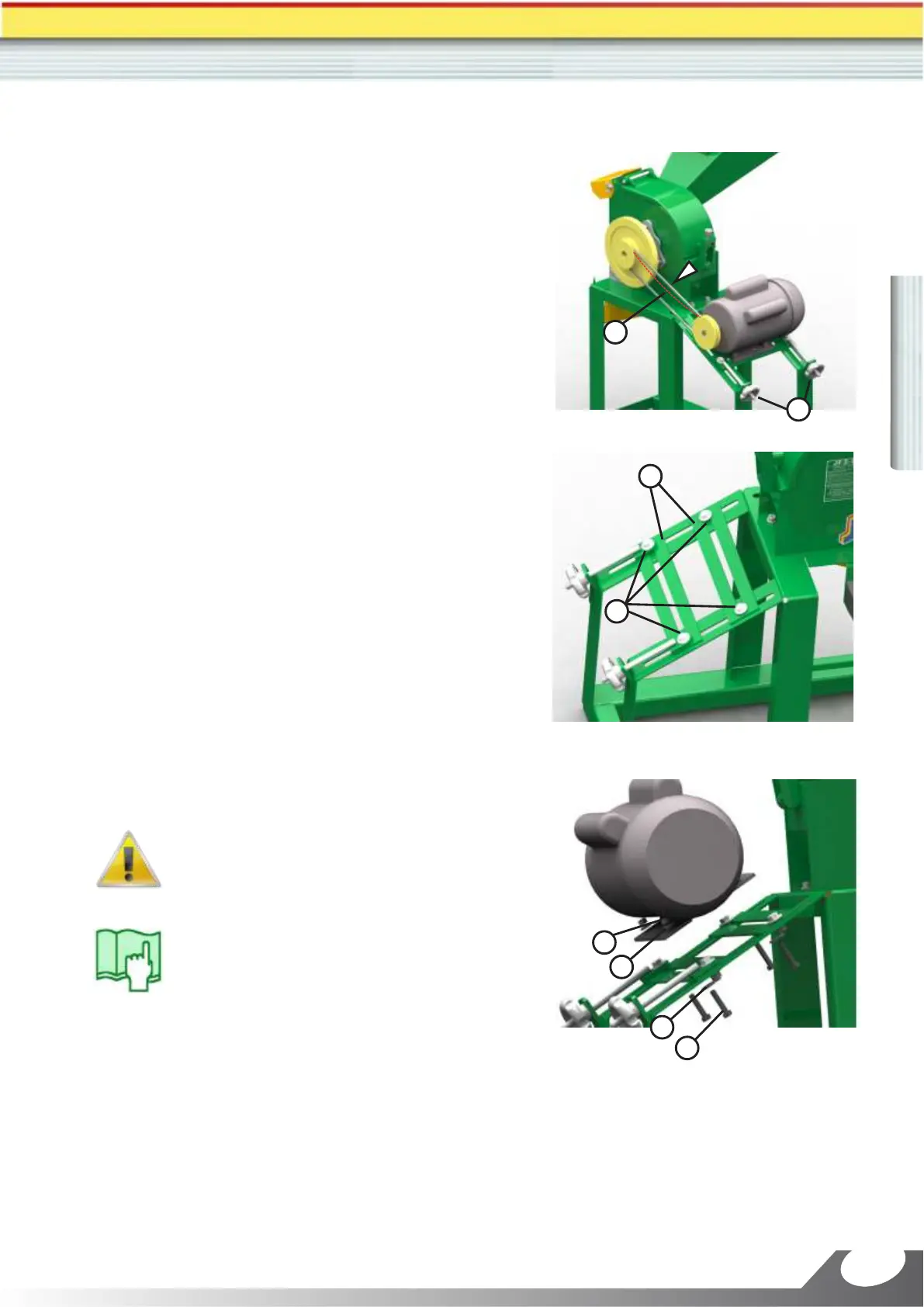

The motor is fixed on a movable base that can be

adjusted by tightening or loosening the sticks (2).

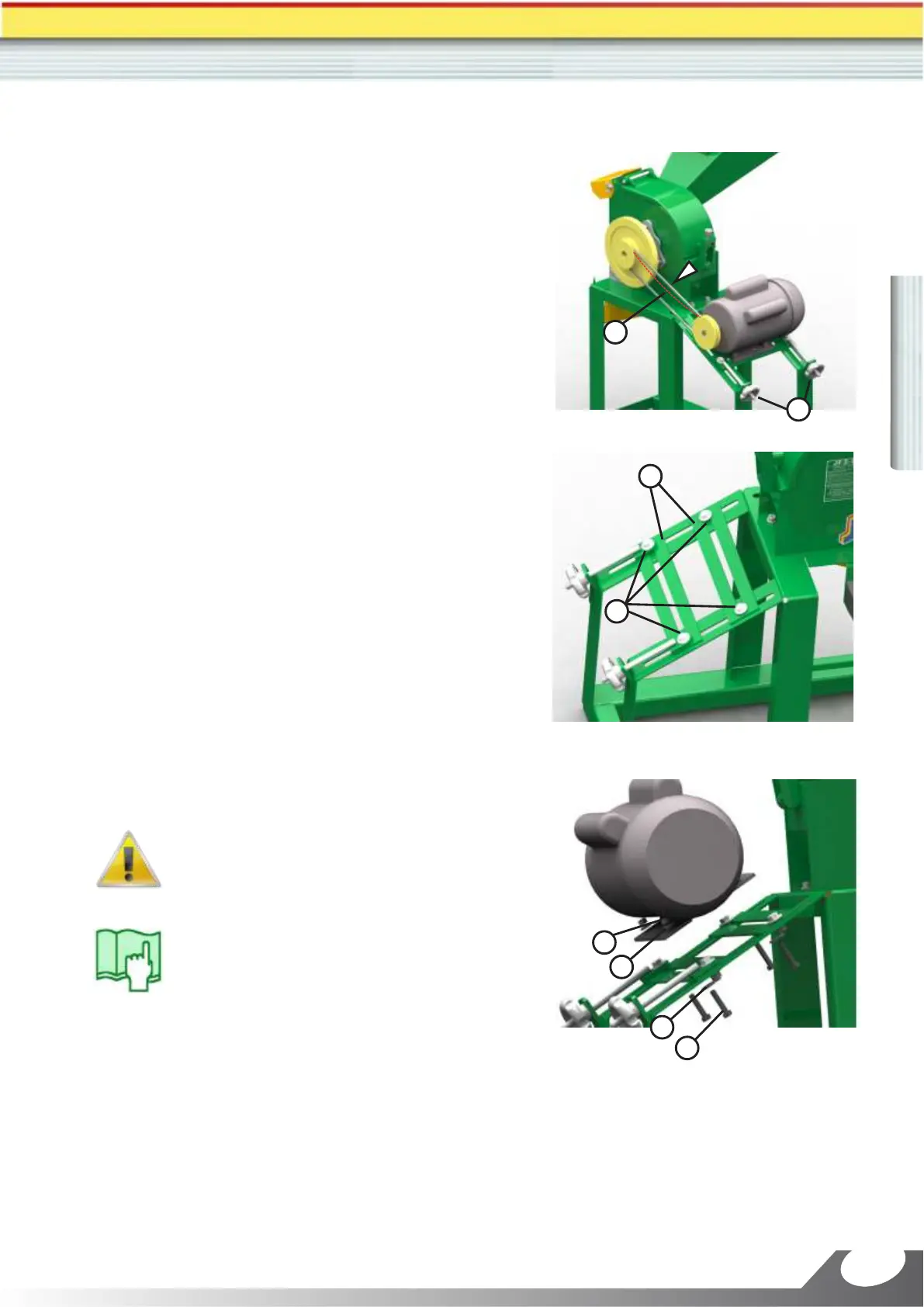

NOTE: Before adjusting the tensioning across the

sticks, must loosen the nuts (B) for the supports (A) can

move easily.

The adjustment is made as follows:

1º- By pushing the sticks, the motor is displaced in the

opposite direction of the machine, thus the belt is

tensioned.

2º- When the sticks is released, the motor is displaced in

the machine direction, thereby the belt tension is

relieved.

NOTE: Do not let the belt completely loose! The

clearance (deflection) should be between 5 and 10 mm.

Check the belt tension (1) each 50 work hours or

weekly and if you assemble a motor, according

instructions on next page.

Motor assembly:

1- Adjust the supports (A) so that the spacing is the

same as the motor base.

2- Next, place the motor in the support, turn the screw

(3) and washer (4) and segure with the washer (5) and

nut (6) in the four extremities of the motor base.

1

2

3

A

4

5

6

Do not forget to re-install the protective

covers. Never operate the machine

without it!

Notes:

1- Grease, oil and dust attack the belt,

generating premature damaging. Therefore,

maintain the belts always very clean.

2- If the belts prevent drying, peeling and/or

free fibers, change them immediately.

B

OPERATION TECHNICAL MANUAL - MILL JF 2D

English

Loading...

Loading...