32

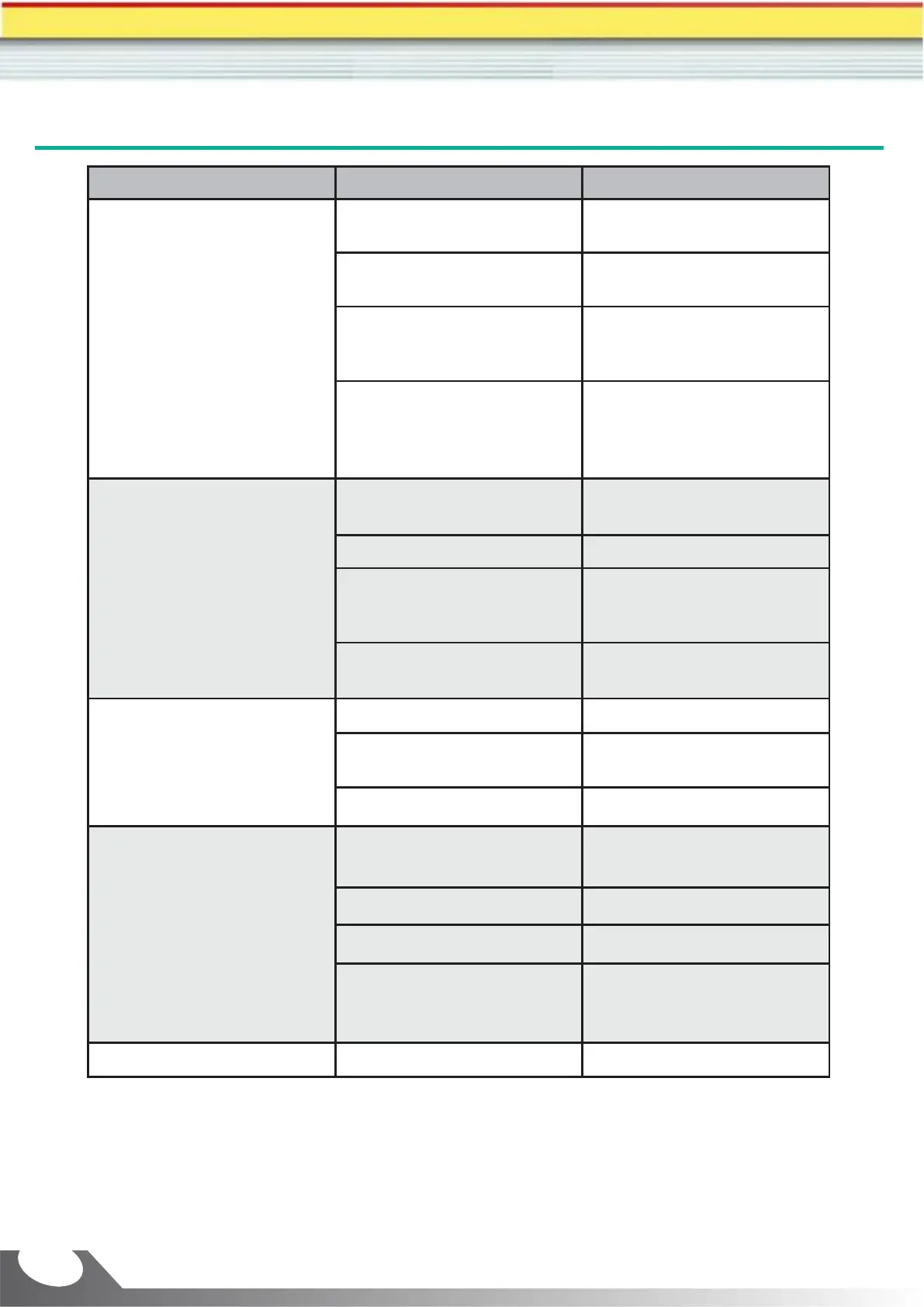

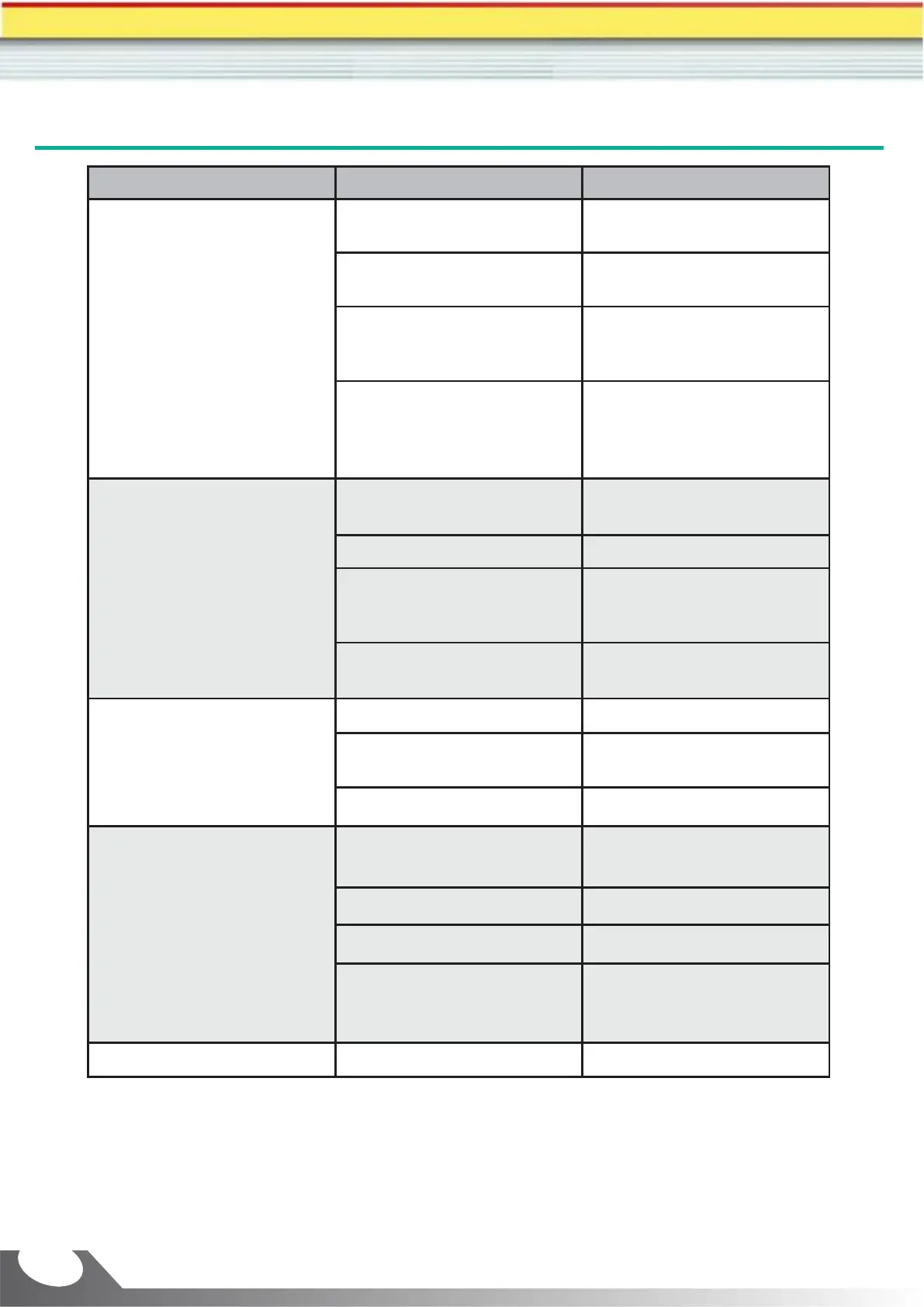

10- Troubleshooting

Excessive machine vibration

The machine is not on a

proper base

Put the machine on a

leveled and rigid base

The anti-vibration rubbers

were not installed

Install it according

instructions in this manual

The impeller is unbalanced

Check the quantity,

assembled position knifes

and hammers

Open the cover of the

impeller compartment and

remove the accumulated

material

The chopped material is

threadlike, i.e., the cut is

insuficient

Knives cutting edge is not

good

Replace the cutting knife

Material put in excess inside

of the feeding nozzle

Supply the machine

uniformly and continuously

without excess

Check the motor power and

pulleys diameter

The disintegrated particles

are not at correct size

Check the motor power and

pulleys diameter

Knives cutting edges is not

good

Material put in excess inside

of the feeding nozzle

Supply the machine

uniformly and continuously

without excess

Loading...

Loading...