Page 13

John Bean VPI System III Operators Manual

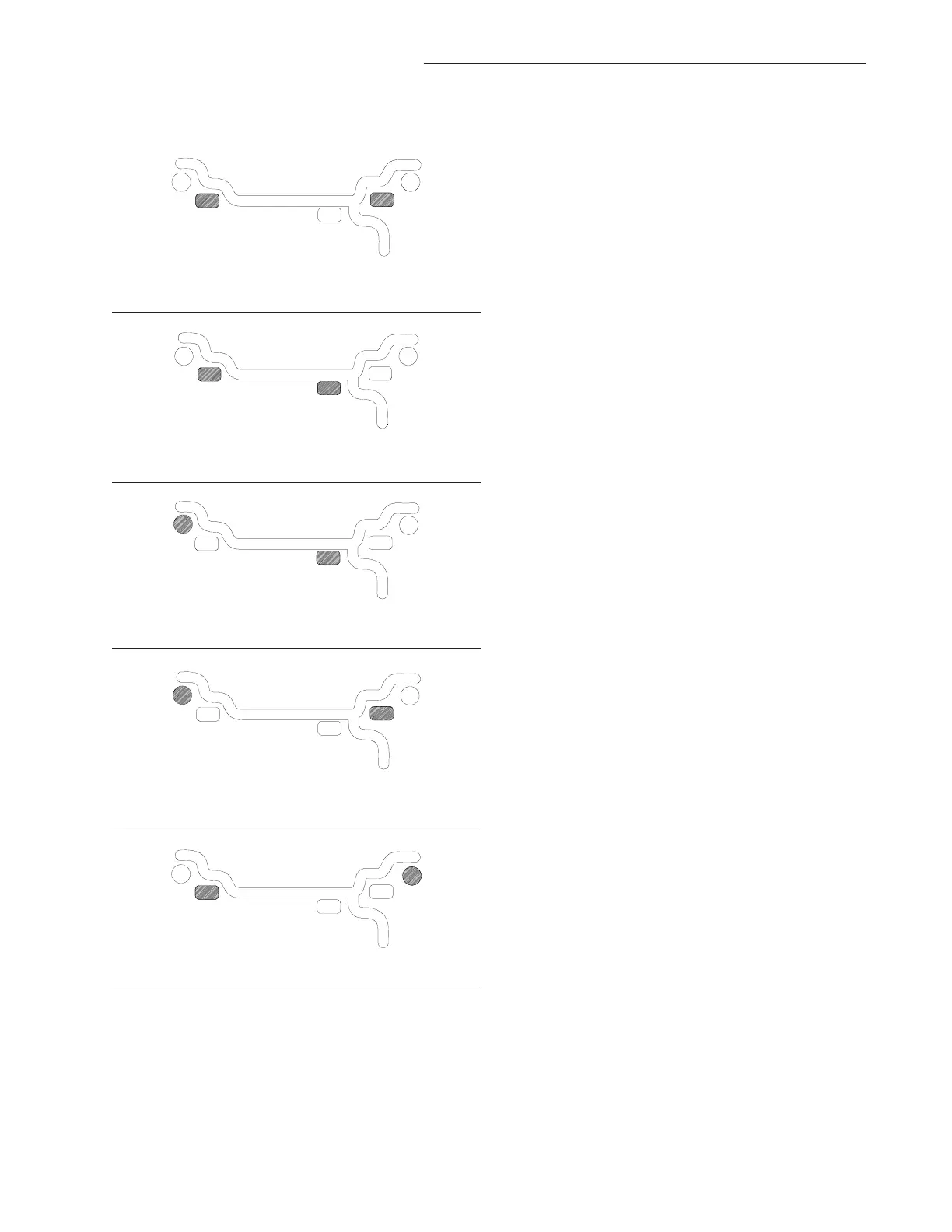

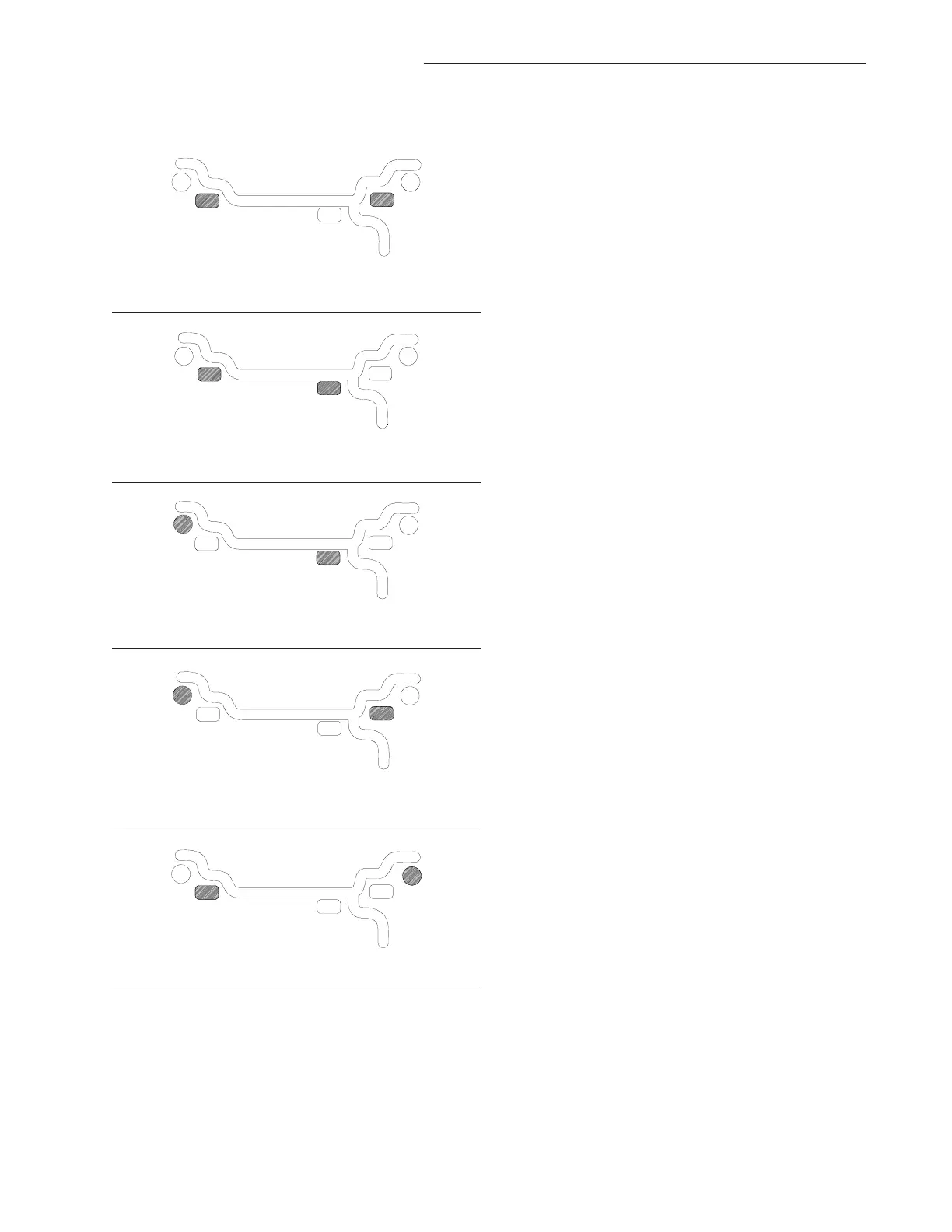

C. ALUMINUM MODES. Balancing using a combina-

tion of hammer-on and adhesive weights as shown in

Figures 17 thru 21.

Figure 17 ALU 1

Figure 18 ALU 2

Figure 19 ALU 3

Figure 20 ALU 4

Figure 21 ALU 5

TO RETURN TO THE DYNAMIC PROGRAM FROM

ANY OF THE ALU PROGRAMS, JUST PRESS Can-

cel/Stop.

4.4 SELECTING OPERATOR PREFERENCES

4.4.1 FINE BALANCING MODE

This balancer measures with the maximum precision

available all the time, 1g / 0.05 oz, however values be-

low 5g / 0.25 oz are shown as zero while in the normal

operating mode. Values exceeding 5g / 0.25 oz are

rounded to the amount of the nearest commercial wheel

weight.

Press the Fine Mode button (number 5 on page 9) to

toggle the display resolution between 5g / 0.25 oz and

1g / 0.05 oz.

4.4.2 OUNCE/GRAMS CONVERSION

Press the OZ/Gr button on the touch panel to toggle

between ounces and grams for weight amount display.

Pressing again will revert to the previous mode.

4.4.3 RIM DIAMETER IN MILLIMETERS

The rim diameter is normally displayed in inches, how-

ever if the value in millimeters is desired, press the F

button followed by the UP or Down arrow button until

“F 7” is displayed”. Press “ENTER”.

Repeat the above operation to convert back to inches.

Example: “dIA ICH” = inches

“dIA ---” = millimeters

4.4.4 OPERATOR SELECTION

Select the desired operator designated A,B,C, D or P1

thru P4. The System III Balancer can store wheel pa-

rameters of four operators and four other stored param-

eters. The Operator button toggles between the stored

locations with each depression.

4.4.5

Weight Miser

™™

™™

™ is a software program

that determines if there is the possibility to re-

move sufficient vibration from a tire and wheel

assembly by applying a lower amount of weight

than the normal balance function recommends.

The amount of residual imbalance left on the

tire and wheel assembly is determined by the

residual threshold tolerance setting.

Assuming that an amount of residual imbalance

accepted currently by the automotive industry

standards is 5 grams for static imbalance and

10 grams for dynamic imbalance, a new fea-

ture Weight Miser™ allows the tire shop to

achieve wheel balancing using less – smaller –

balancing weights.

Loading...

Loading...