Page 12

FAILURE TO TIGHTEN QUICK NUT SECURELY

MAY RESULT IN SERIOUS PERSONAL INJURY.

DO NOT USE A HAMMER TO TIGHTEN THE

QUICK NUT.

TO RELEASE THE QUICK NUT, UNSCREW A FEW

TURNS TO REDUCE THE AXIAL PRESSURE,

THEN PRESS THE UNLOCK LEVER AND SLIDE

AWAY FROM THE SHAFT.

5. Check that the wheel rotates true by turning the wheel

several revolutions while noting any excessive runout.

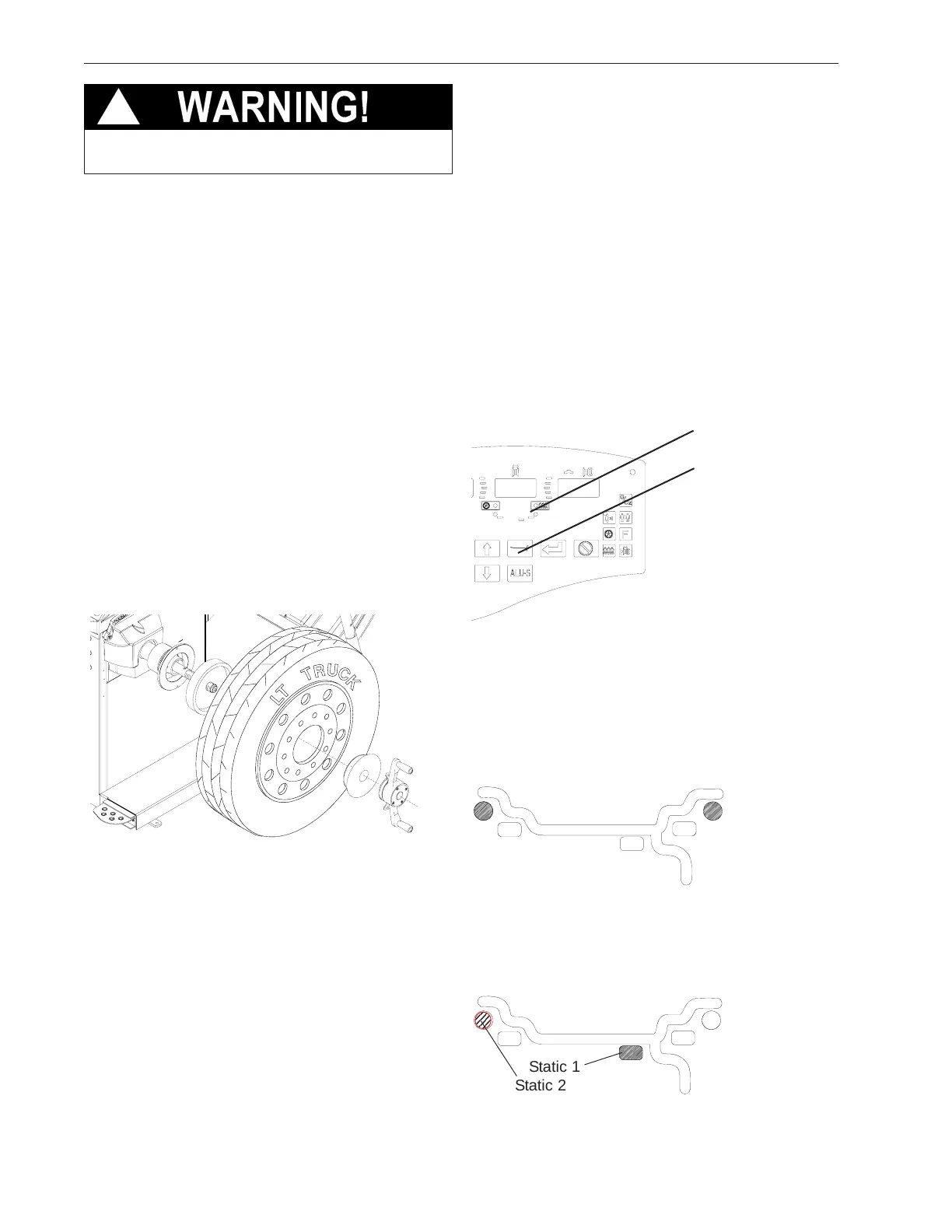

4.2.3 CENTERING LIGHT-TRUCK WHEELS

An optional offset spacer may be required for some light

truck wheels and reverse-offset wheels that must be

moved away from the balancer mounting flange. The ex-

tension adaptor is often used with the 5-1/4 inch diam-

eter light truck cone.

Install the spacer on the mounting flange, then mount

the wheel, using the front cone method (Figure 13)

Figure 13

4.3 MODE SELECTION

The majority of balancing takes place in the default 2-

plane dynamic mode which is displayed as "2 PL"

(location 1). Hammer-on clip weights will be placed on

both inside and outside of the rim edge. If required,

select an optional weight placement mode by pressing

the Mode button until the appropriate placement mode

is displayed.

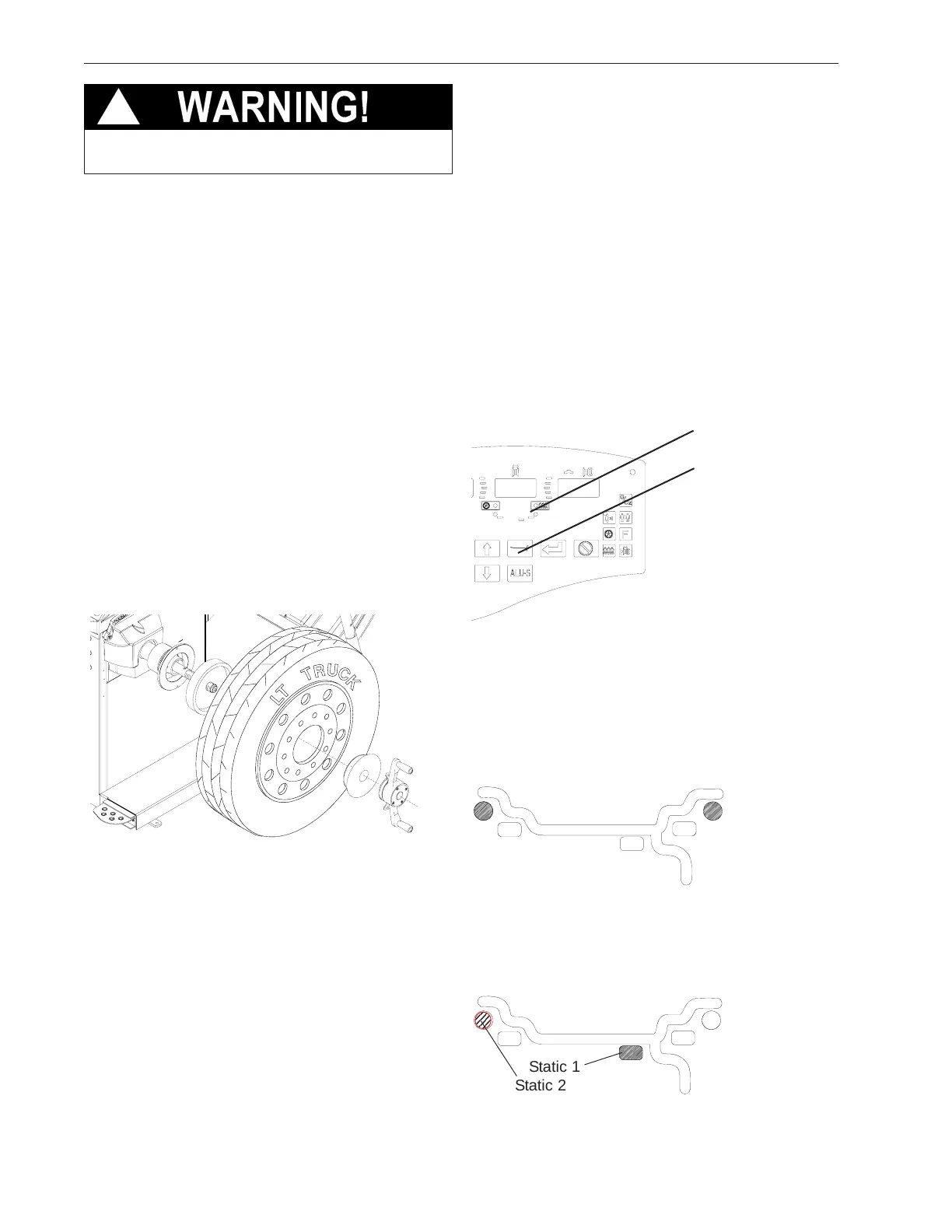

4.3.1 WEIGHT PLACEMENT MODES

Before spinning the wheel (although it may be done af-

terwards) choose the appropriate balancing mode for the

wheel. To select the various placement modes press the

Mode button until placement LEDs indicate desired

placement position.

The balancing modes available are:

A. DYNAMIC (two planes), suggested for all steel rims.

In this case the wheel weights must be clipped onto the

rim edges. This function is selected as a default and

the LEDs corresponding to the wheel weight location

are lit on (Figure 15).

B. STATIC (single plane - Figure 16). Suggested for nar-

row rims (3" or less). Use a single corrective weight placed

in the center or inner edge of rim as illustrated in Figure

16.

Figure 14

Figure 15

Figure 16

!

Mode Button

Indicator LEDs

Static 1

Static 2

Loading...

Loading...